Swivel construction method for bridge in water-rich area

A construction method and swivel technology, applied to bridges, bridge parts, bridge materials, etc., can solve the problems of large working space, time-consuming and labor-consuming, and affecting swivel, so as to achieve small equipment occupation, simplify positioning procedures, and ensure swivel body effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

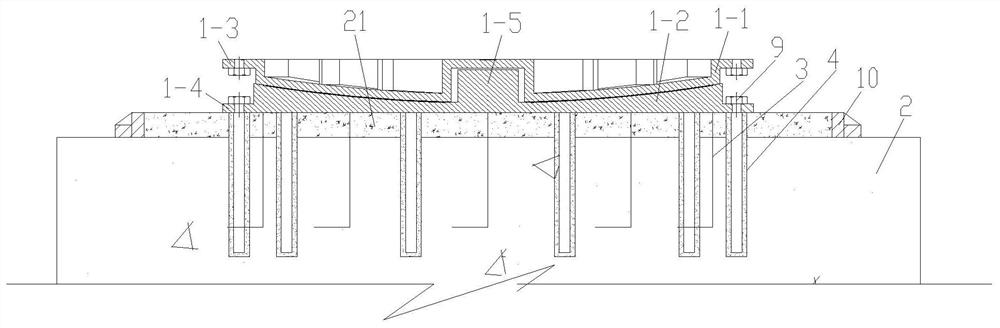

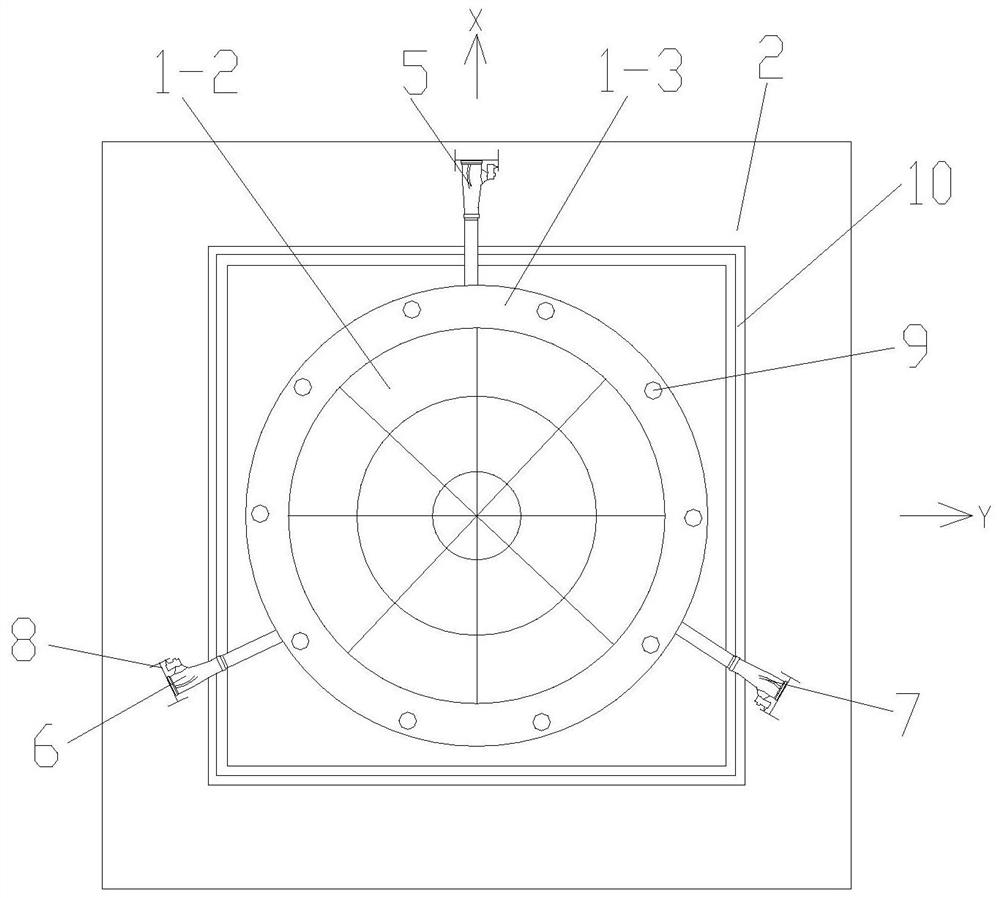

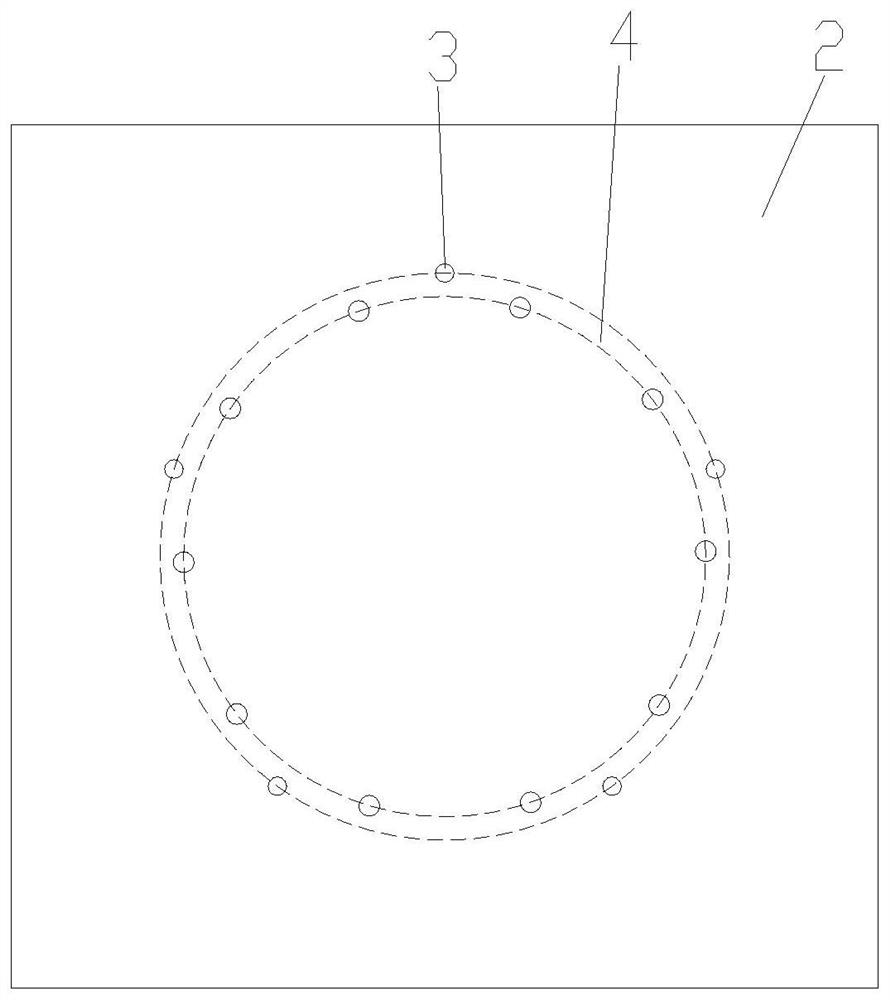

[0077] Such as Figure 1 to Figure 14 As shown, a swivel construction method of a bridge in a water-rich area of the present invention, the method adopts a swivel spherical hinge support 62 arranged at the bottom of the main pier 22 of the bridge to realize the swivel, and the swivel spherical hinge support includes The upper ball pendulum 1-1, the lower ball pendulum 1-2, and the rotating shaft 1-5 arranged between the upper ball pendulum 1-1 and the lower ball pendulum 1-2, the upper ball pendulum 1-1 and the lower ball pendulum 1-2 2 vertical connection, the upper ball pendulum 1-1 is provided with an annular top seat 1-3, the lower ball pendulum 1-2 is provided with an annular base 1-4, and the annular base 1-4 is provided with a plurality of Circumferentially arranged anchor bolts 9, the method comprises the following steps:

[0078] Step 1. Installation of the temporary water-stop structure of the swivel spherical hinge support;

[0079] Step 2. The construction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com