Heater built-in valve

A technology for heaters and valve stems, which is applied to valve heating/cooling devices, valve lifts, valve details, etc. It can solve problems such as uneven temperature, achieve easy operation, easy replacement, and reduce the difficulty of plugging and unplugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be described in detail below by way of example with reference to the accompanying drawings. However, the relative arrangement and the like of the components described in the present embodiment are merely illustrative examples unless otherwise specified, and do not limit the scope of the present invention thereto. In addition, for the sake of convenience, the directions of members and the like may be referred to as up, down, left, and right based on the directions on the drawings, but these directions do not limit the scope of the present invention.

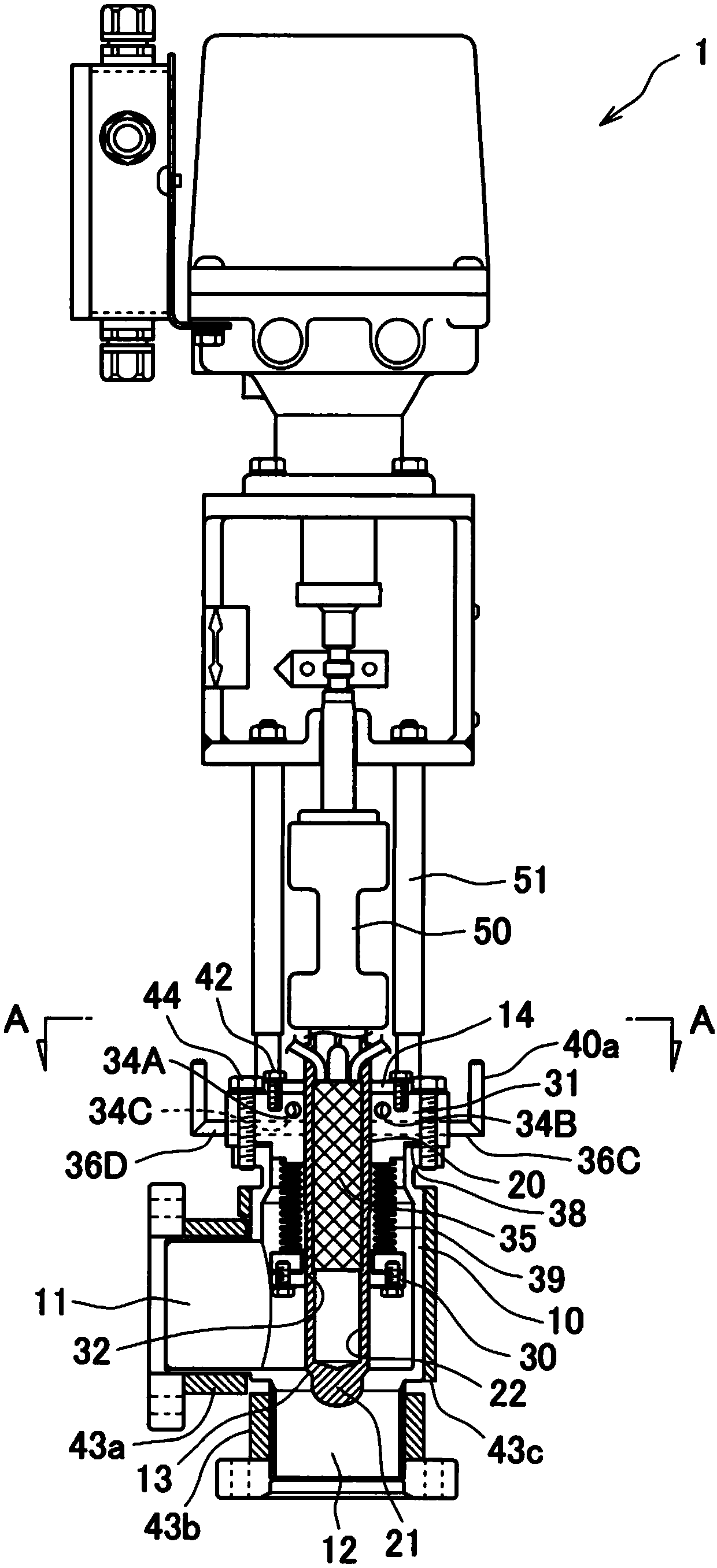

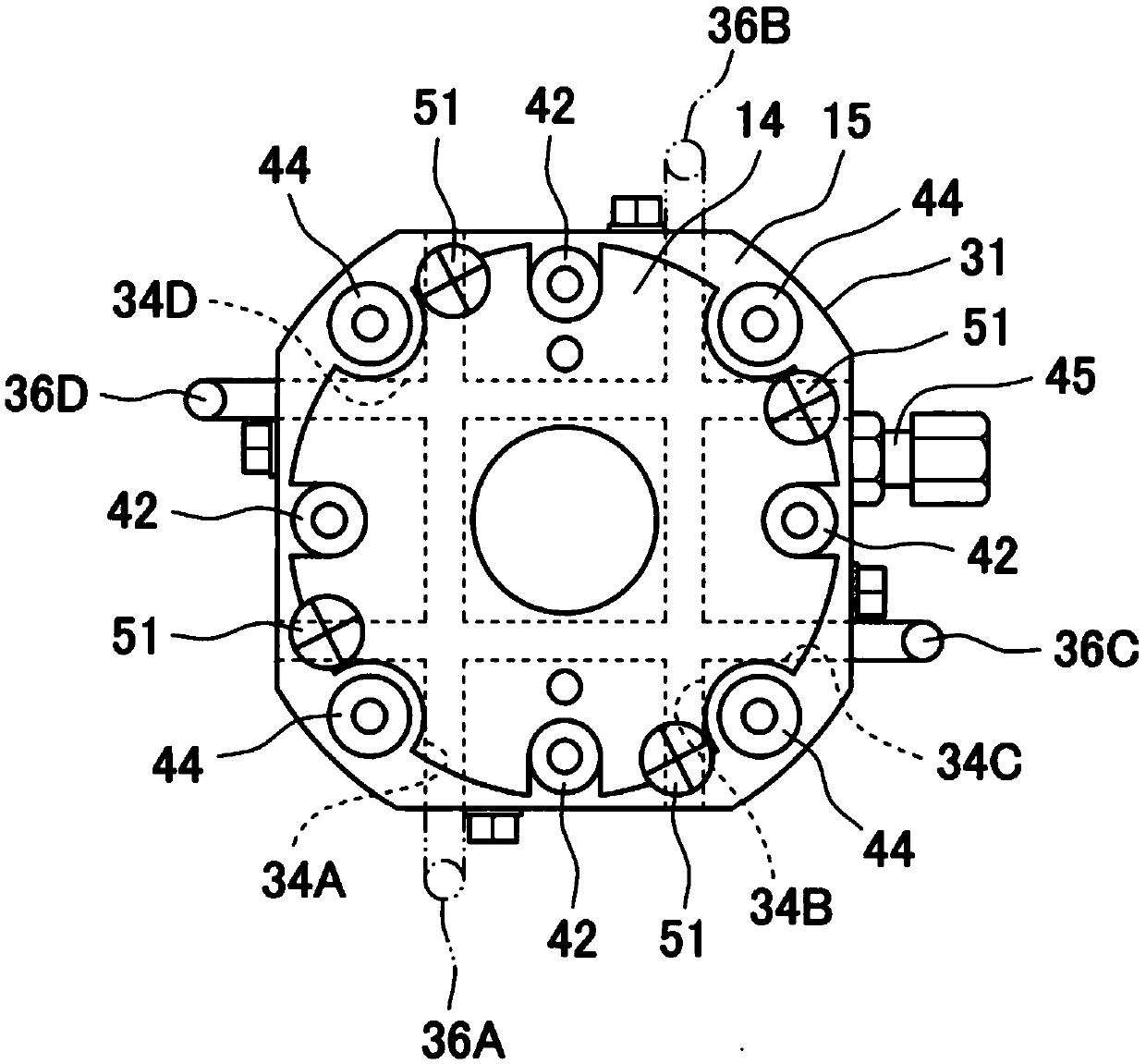

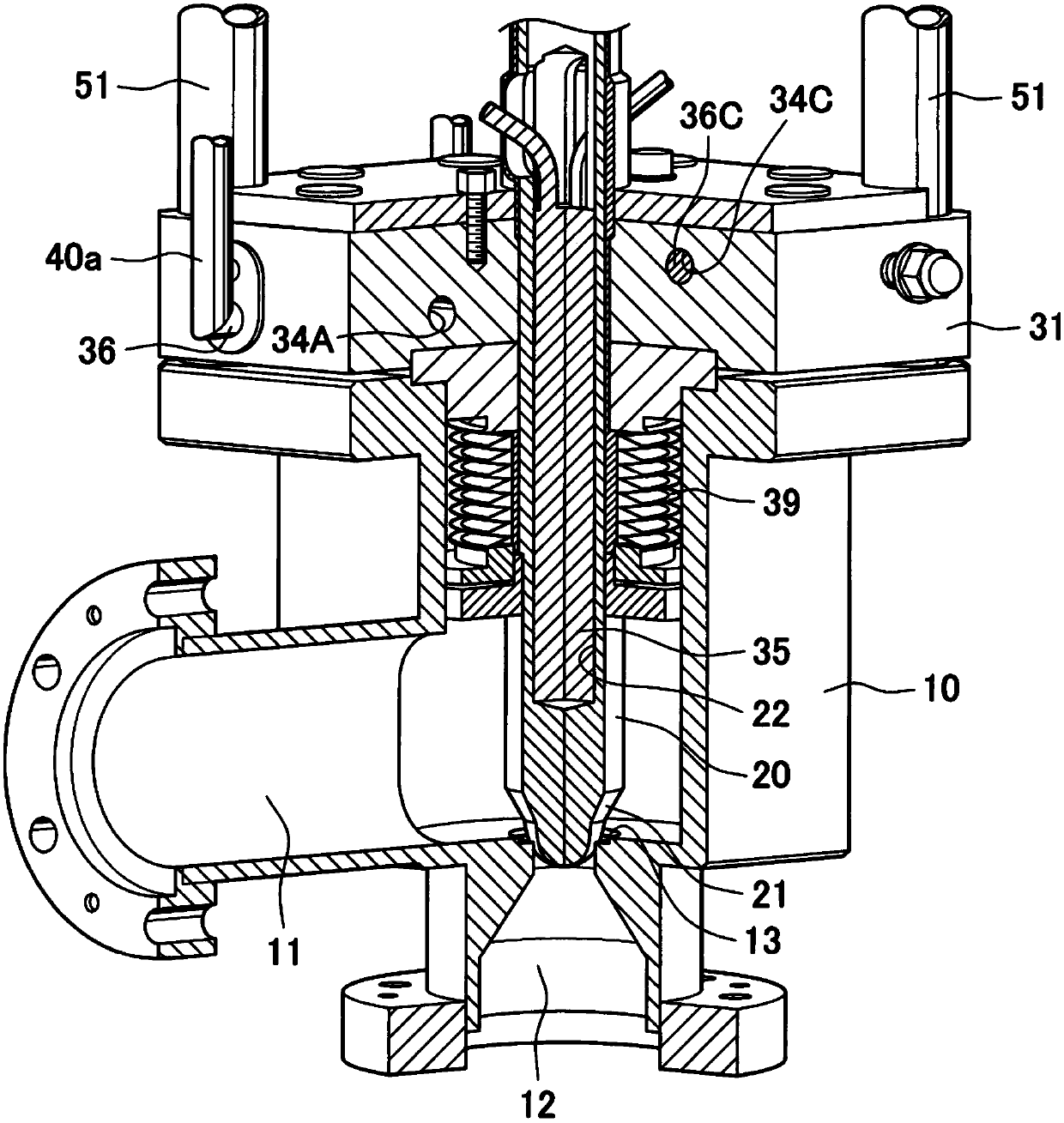

[0037] figure 1 It is a figure which shows Example 1 of the heater built-in valve of this invention, This valve 1 is also called a heater built-in vacuum on-off valve.

[0038] The valve body 10 is provided with an inlet channel 11 and an outlet channel 12 , and a valve seat 13 is formed therebetween. The fluid flows in from the left and flows downward with the valve ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com