Water tap direct-connected flash refrigerator and its assembly

A faucet and direct-connection technology, which is applied in the field of faucet direct-connection fast refrigerators and their assemblies, can solve the problems of poor mechanical properties, non-wear resistance, poor sealing, etc., achieve high thermal conductivity, ensure refrigeration efficiency, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Referring to the accompanying drawings, the tap direct-connected flash refrigerator and the tap direct-connected flash refrigerator assembly involved in the present invention will be described in detail.

[0039]

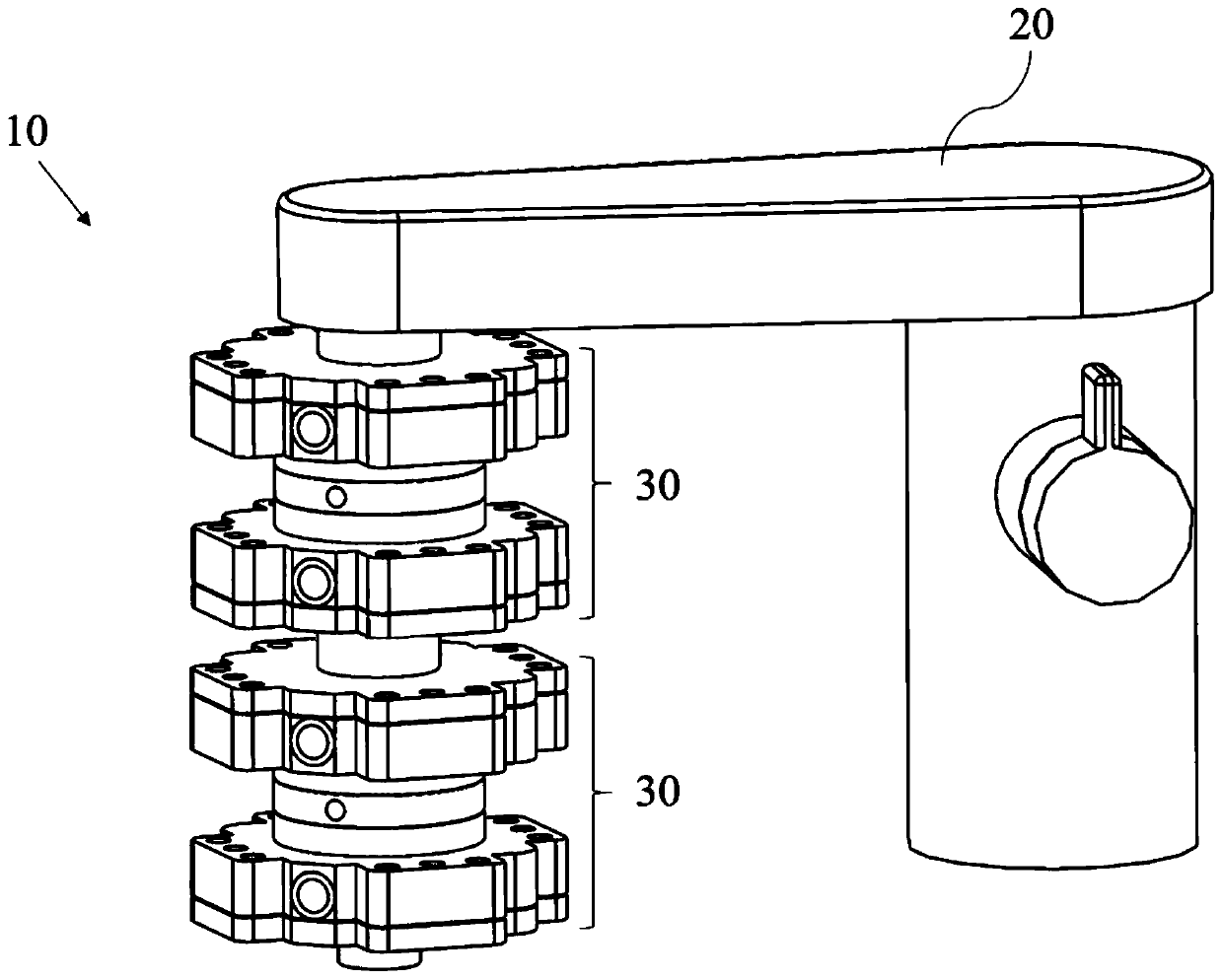

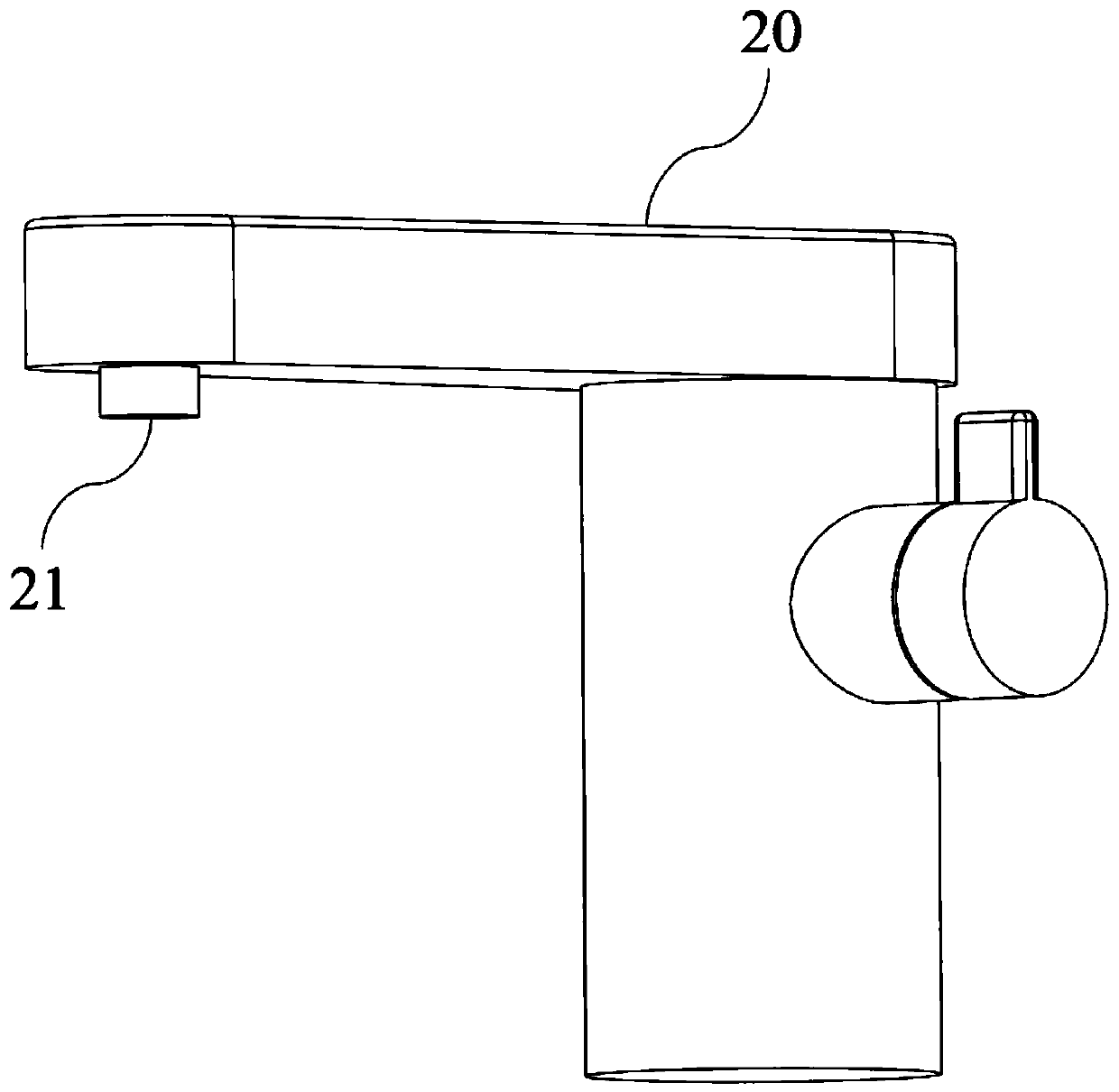

[0040] Such as Figures 1 to 5 As shown, the faucet direct-connected flash refrigerator assembly 10 communicates with the water faucet 20, and cools the water delivered by the water faucet 20. In this embodiment, the faucet direct-connected blast refrigerator assembly 10 includes two refrigerators 30 connected to each other.

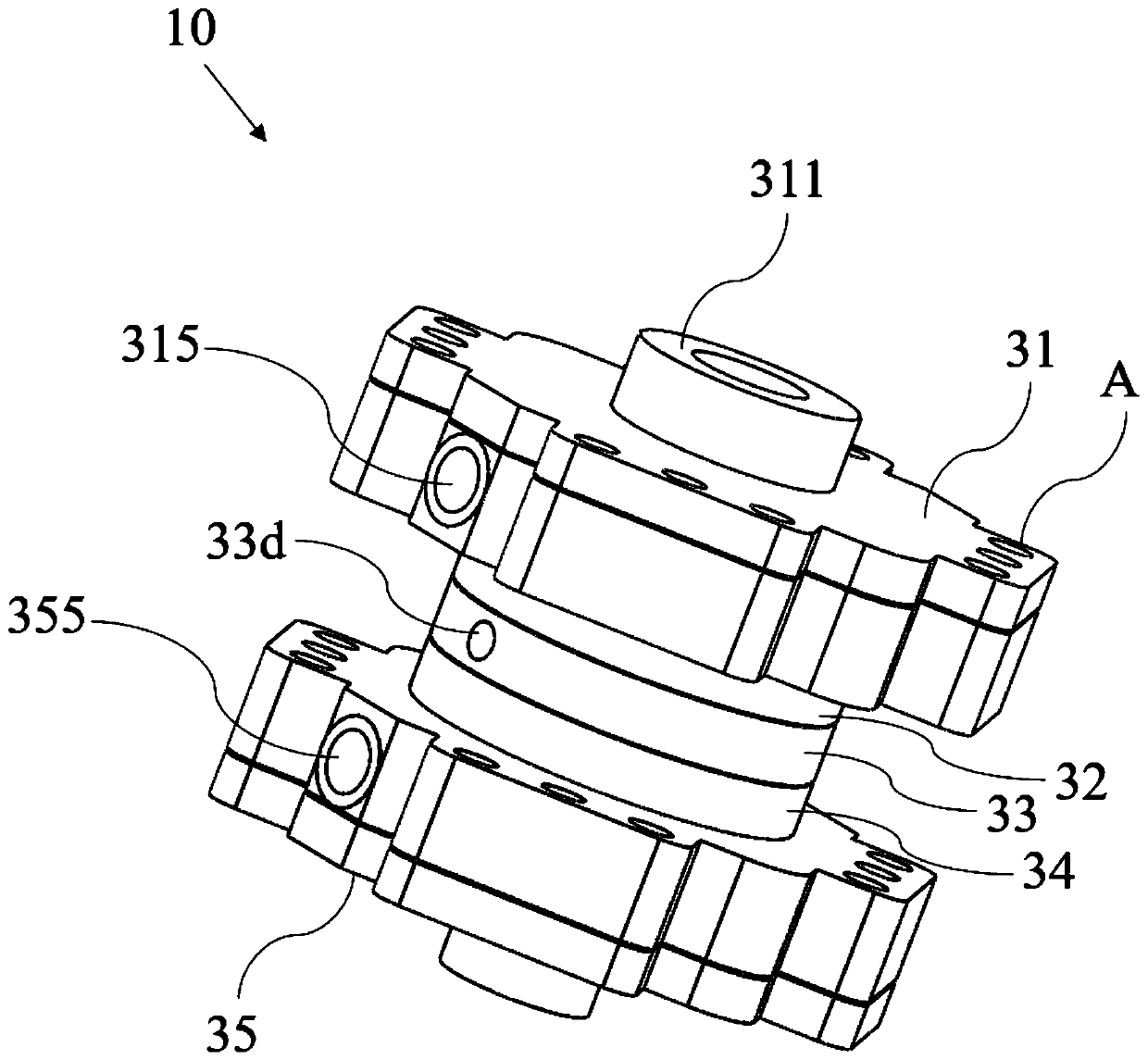

[0041] Such as Figures 1 to 11As shown, the refrigerator 30 includes a primary liquid cooling block 31, a primary cooling sheet 32, a temperature conducting sheet 33, a secondary cooling sheet 34, a secondary liquid cooling block 35, two sealing rings 36 and 37, and a temperature measuring member 38 And temperature control member 39.

[0042] Such as Figure 1~2 As shown in 6-7, the upper surface of the primary liquid cooling blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com