Heat exchange two-layer pipe sealing structure and installing fixture and method thereof

A technology of sealing structure and installation fixture, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc., which can solve the problems of large impact on the fatigue life of the sealing ring, large volume of the sealing structure, and pollution of two media, etc. Achieve the effect of stable and durable sealing effect, good sealing effect and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

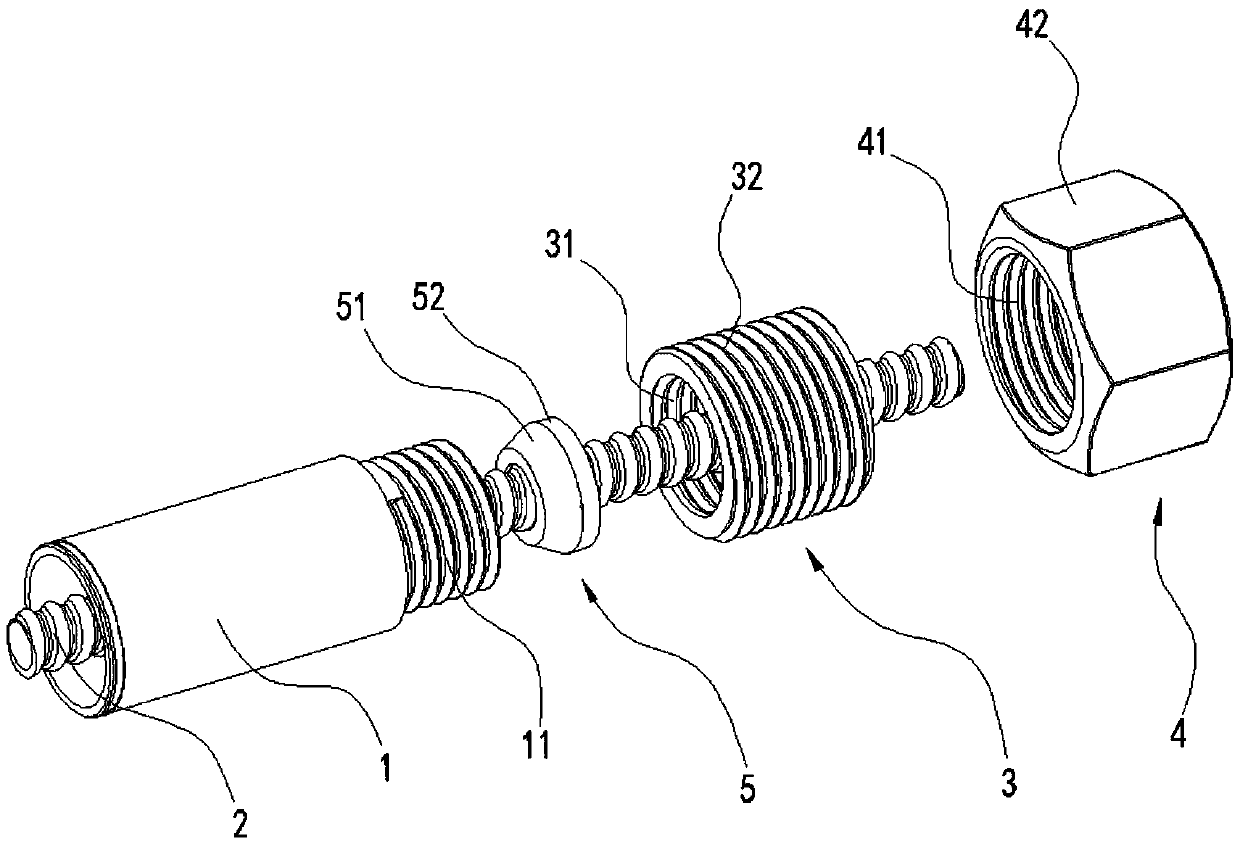

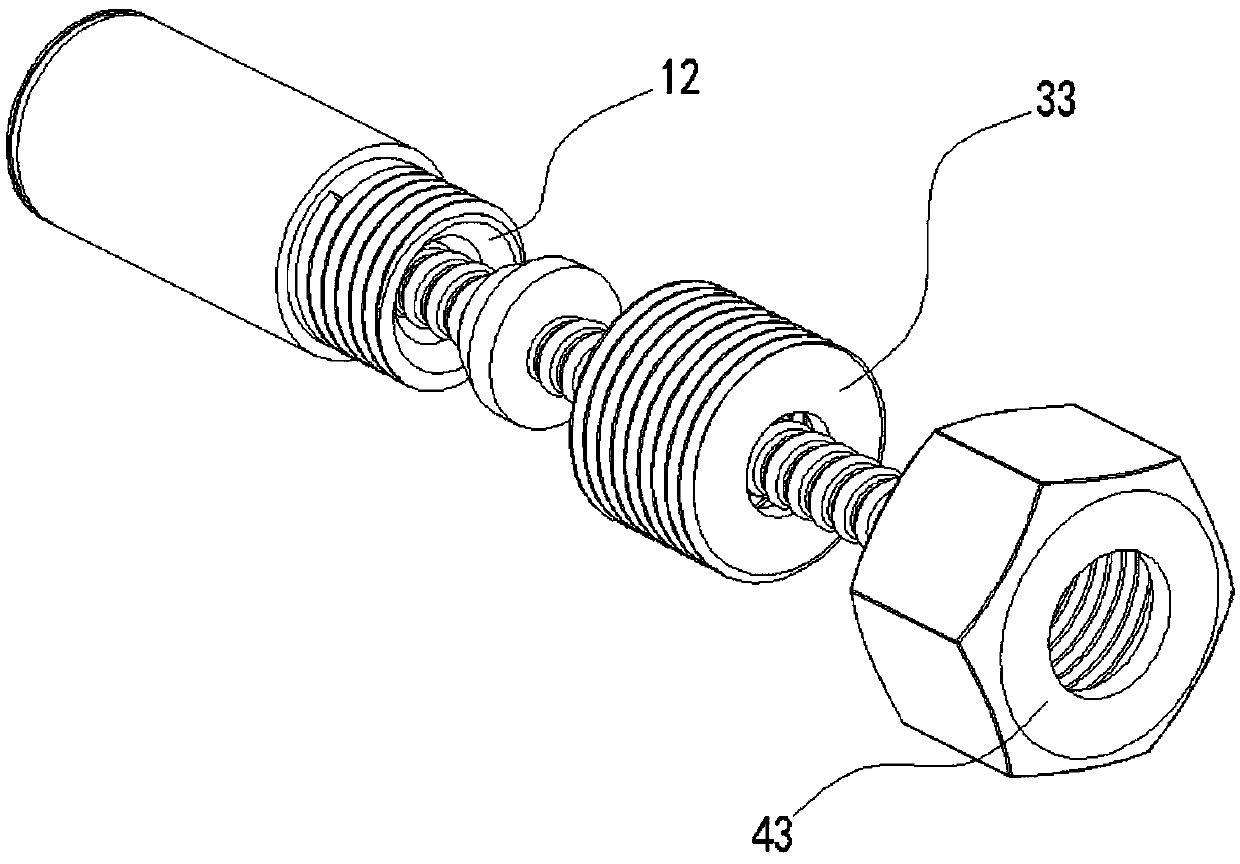

[0027] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine figure 2 - Figure 9 The accompanying drawings describe the present invention in further detail.

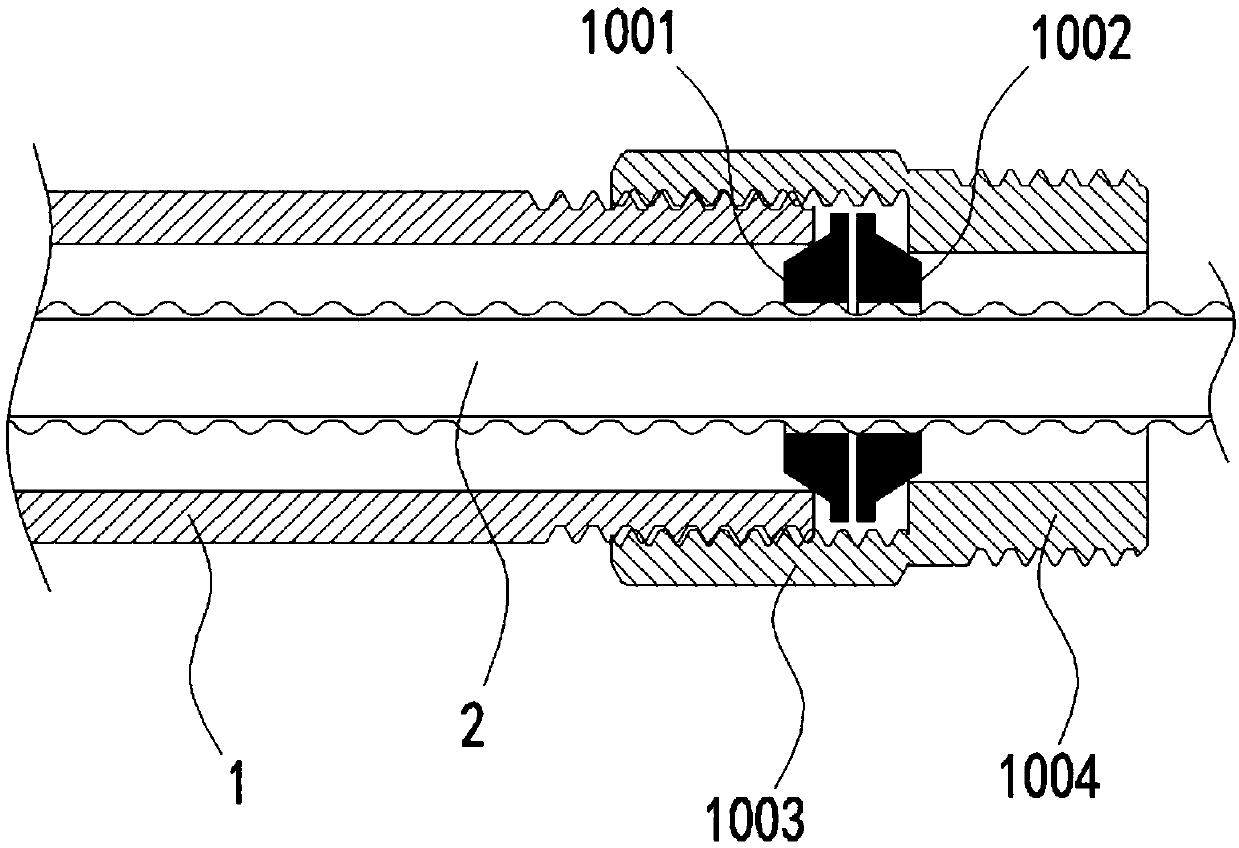

[0028] refer to figure 2 - Figure 5 As shown, a heat exchange double-layer tube sealing structure includes an outer tube 1, an inner tube 2 arranged inside the outer tube 1, and a sealing member 5, and the sealing member 5 is sleeved on the inner tube 2; the sealing member 5 includes an outer slope 51 and Cylinder 52, the cylinder 52 is affixed to the larger end of the outer slope 51, the diameter of the cylinder 52 is the same as the diameter of the larger end of the outer slope 51;

[0029] The end 11 of the outer tube 1 has an inner bevel 12, and the end of the inner bevel 12 with a larger diameter faces the opening of the end 11 of the outer tube 1, and the outer bevel 51 matches the inner bevel 12;

[0030] The outer wall of the outer in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com