Current transformer

A technology of current transformer and conductive tube, which is applied in the direction of inductor, inductor/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc. It can solve the problems of poor insulation level of transformer and difficult secondary molding, etc. To achieve the effect of ensuring insulation level, improving production efficiency and reducing partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

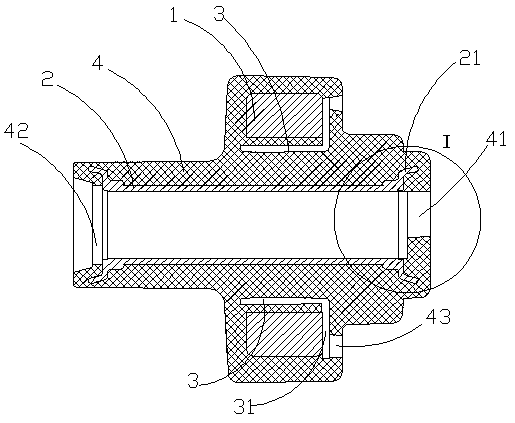

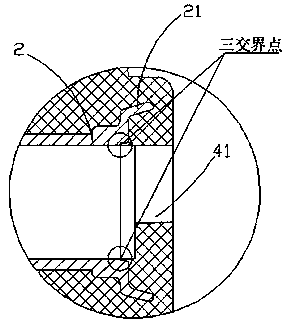

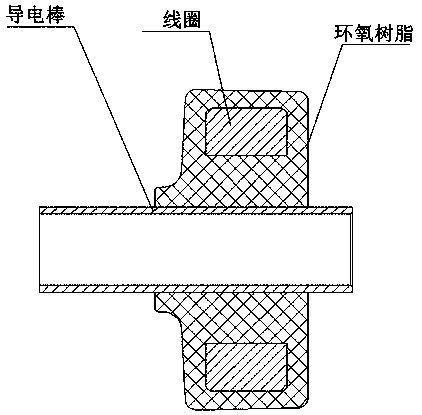

[0021] The embodiment of the present invention discloses a current transformer, such as figure 1 , figure 2 As shown, it includes a coil 1, a conductive tube 2, a low-voltage shield 3, and an insulator 4. The coil 1, the conductive tube 2, and the low-voltage shield 3 are all located in the insulator 4, and the low-voltage shield 3 is a cylinder with two ends open. The low-voltage shield 3 is inserted into the coil 1, the low-voltage shield 3 is set outside the conductive pipe 2, the insulator 4 is made of epoxy resin, and the insulator 4 is provided with a first connection hole 41 , the second connection hole 42 , the first connection hole 41 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com