Piezoelectric microphone

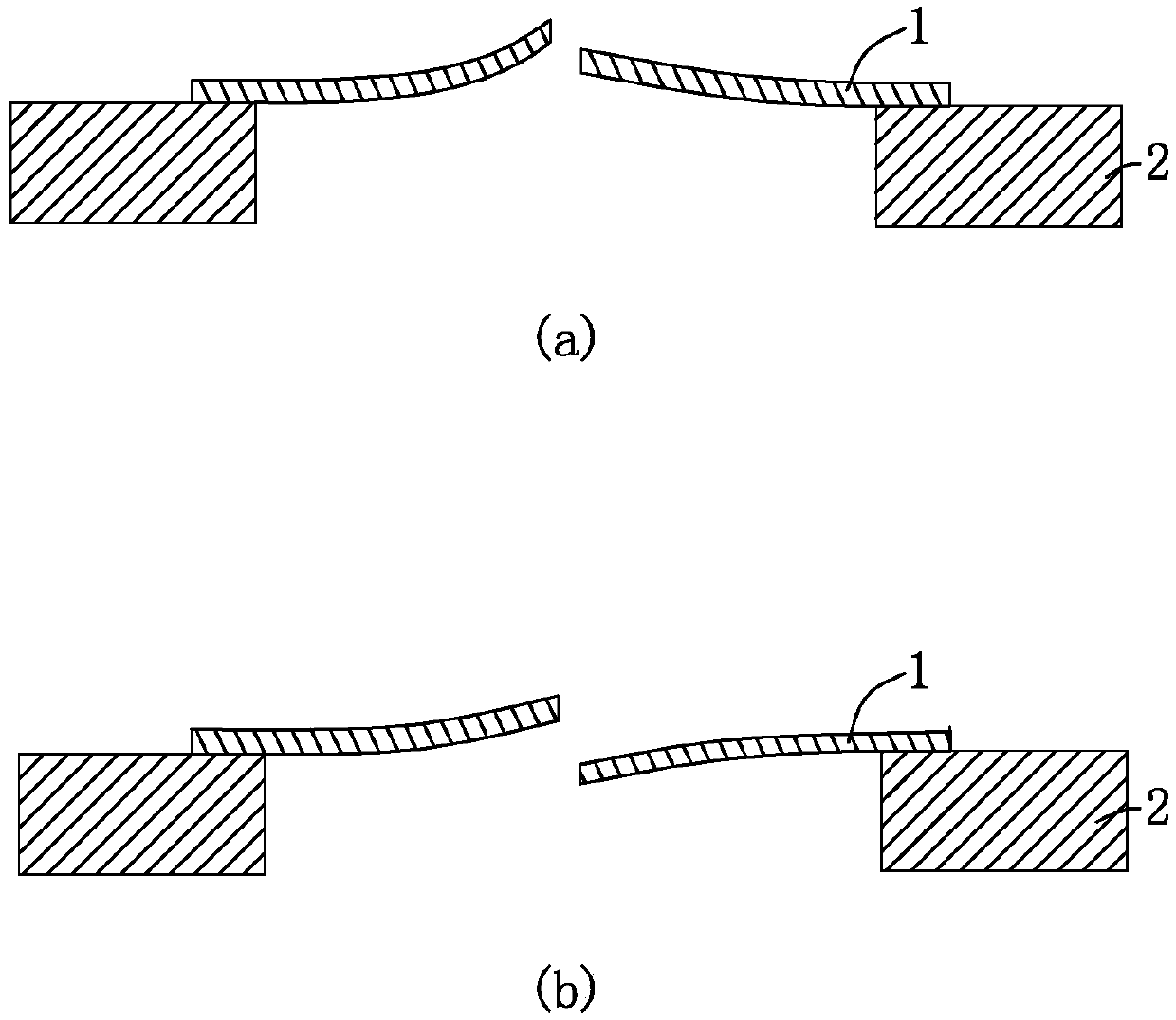

A microphone and piezoelectric technology, which is applied in the field of acoustic-electric conversion, can solve the problems affecting the performance of the microphone and the deformation of the flap of the diaphragm, and achieve the effect of reducing the gap, improving the uniformity, and improving the consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

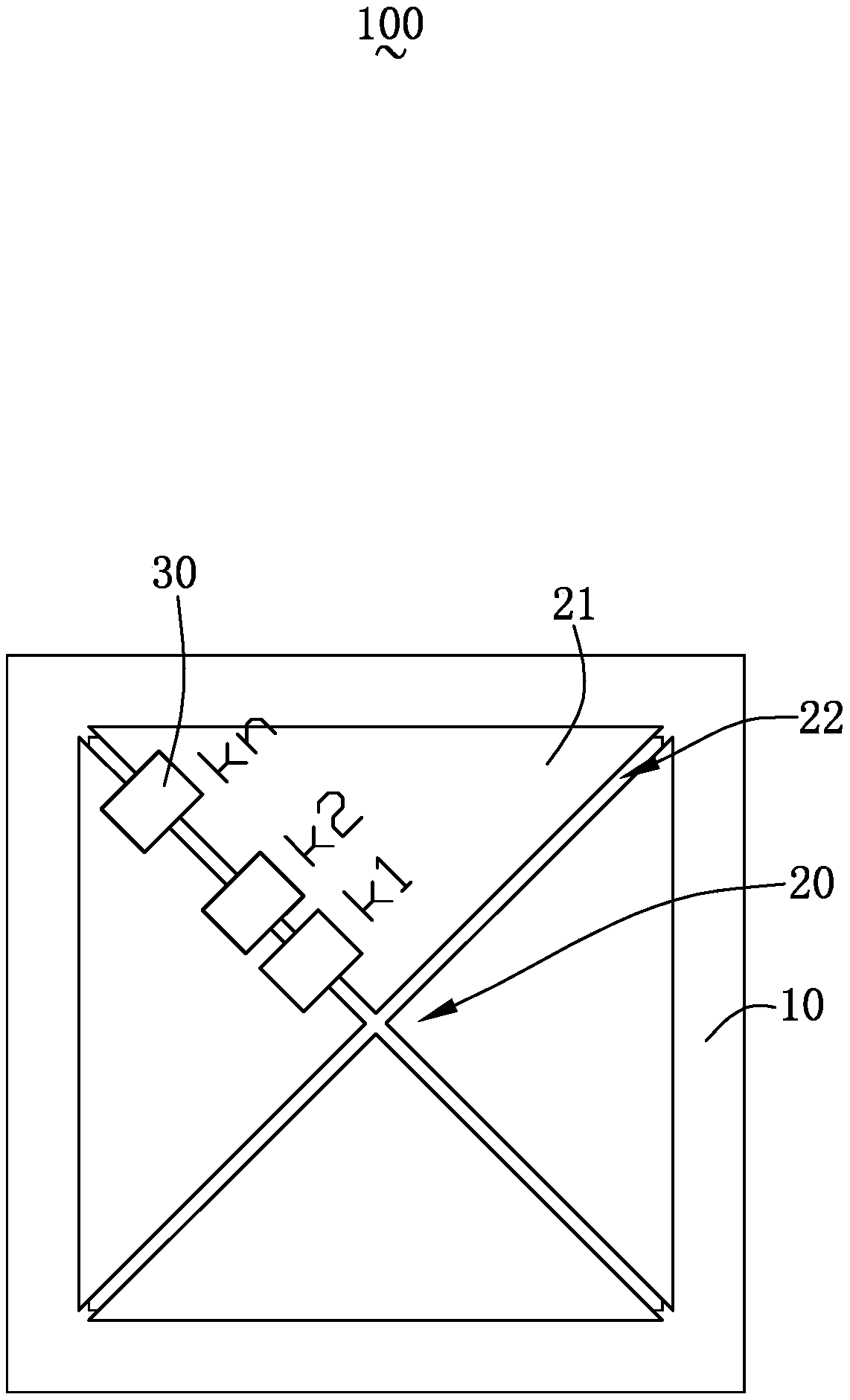

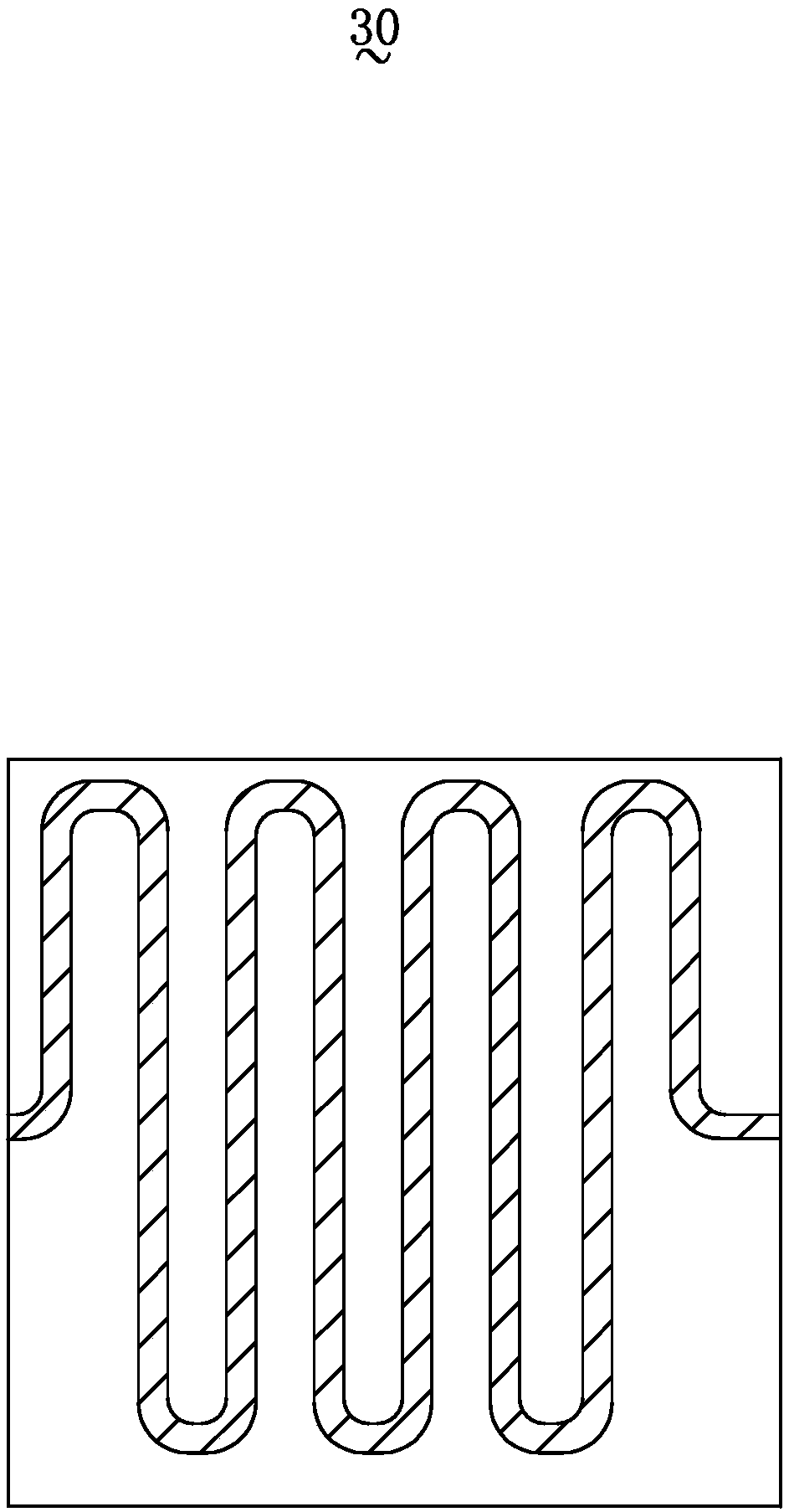

[0026] Please refer to figure 2 and image 3 . This embodiment provides a piezoelectric microphone 100, which includes a substrate 10 with a cavity back, a piezoelectric cantilever diaphragm 20 fixed on the substrate 10, and a piezoelectric cantilever diaphragm 20 fixed on the piezoelectric microphone 100. The elastic expansion part 30.

[0027] The piezoelectric cantilever beam diaphragm 20 is composed of a plurality of diaphragms 21, one end of each diaphragm 21 is fixed to the base 10, the other end is suspended above the back cavity, and each adjacent two diaphragms The flaps 21 are spaced apart to form gaps 22 .

[0028] It should be noted that, in this embodiment, four valves 21 are provided, and all four valves 21 have a triangular structure, and the four valves 21 connect the piezoelectric cantilever diaphragm 20 are surrounded by a rectangular structure. Correspondingly, four gaps 22 are correspondingly provided. Certainly, in other embodiments, the number of t...

Embodiment 2

[0040] Please refer to Figure 4 . This embodiment provides a piezoelectric microphone 200, the structure of the piezoelectric microphone 200 is basically the same as that of the piezoelectric microphone 100 in Embodiment 1, the difference lies in:

[0041]The piezoelectric cantilever diaphragm 120 of the piezoelectric microphone 200 is composed of four fan-shaped diaphragms 121 , and the four diaphragms 121 surround the piezoelectric cantilever diaphragm 120 into a circular structure. There are a plurality of elastic stretchable members 130 and they are sequentially distributed between two adjacent valves 121 in the same group.

[0042] Compared with the related art, the piezoelectric microphone of the present invention connects two adjacent valve flaps by arranging the elastic elastic member between at least one group of two adjacent valve flaps, and the elastic elastic member can The adjacent valve flaps are limited in the same plane, and the elastic stretchable member ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com