Heat pipes with non-condensable gases

A gas and heat pipe technology, applied in the field of heat pipes with non-condensable gas, can solve the problems that electronic components cannot work efficiently, and electronic components cannot reach the working temperature smoothly, so as to achieve the effect of increasing practicability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

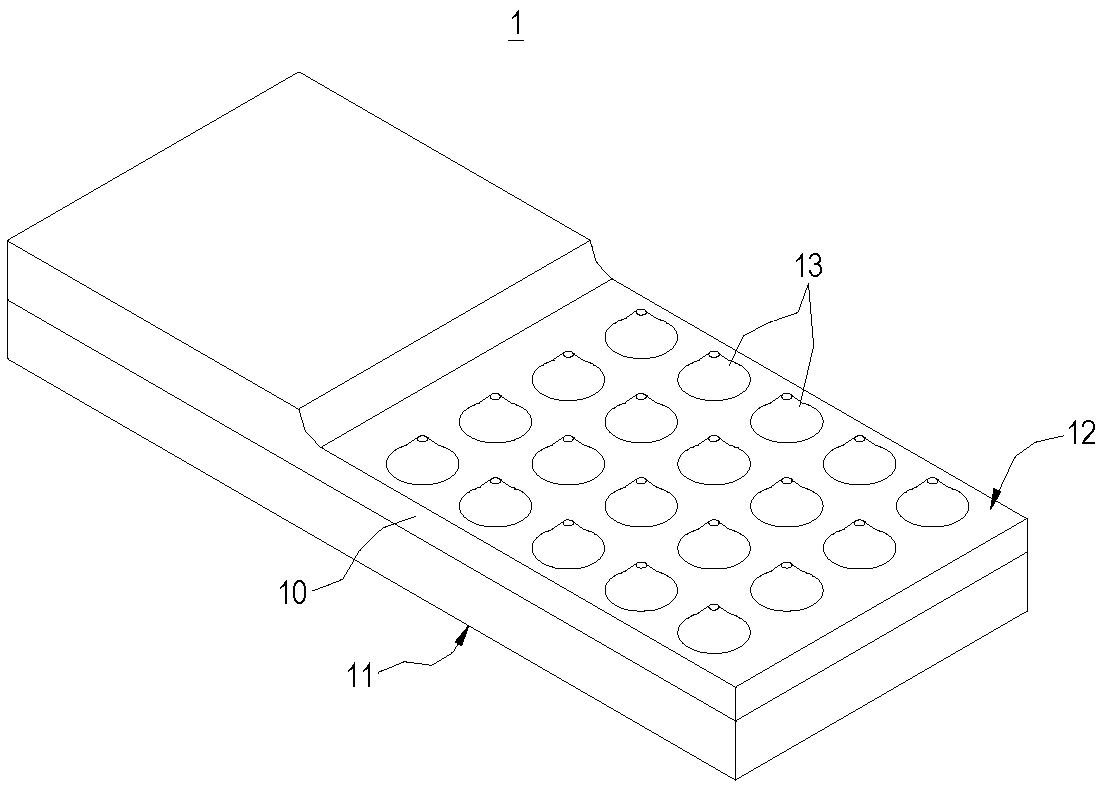

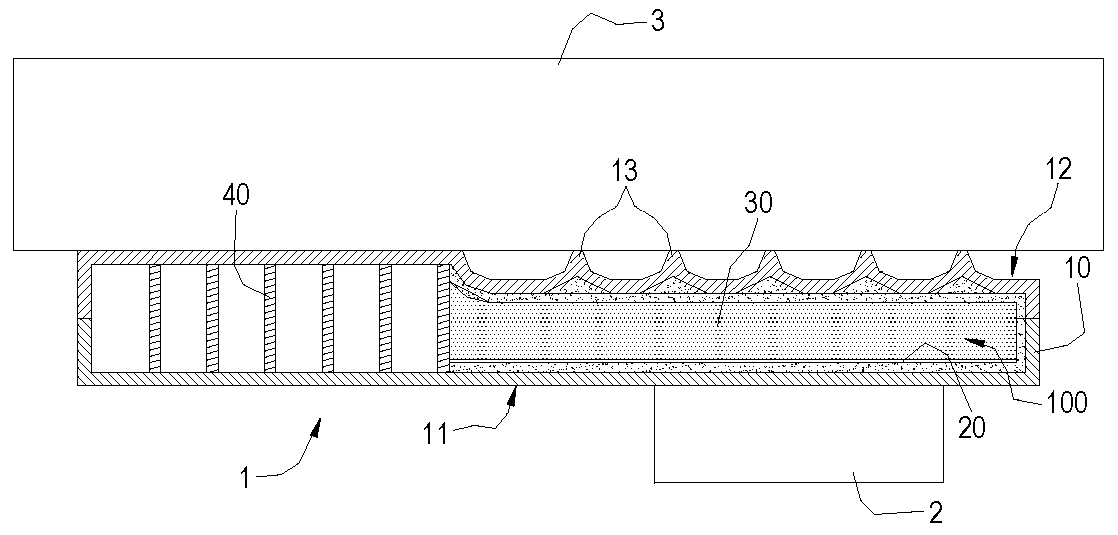

[0015] refer to Figure 1 to Figure 3 Shown are the three-dimensional appearance schematic diagram, the use schematic diagram and the cross-sectional schematic diagram of the heat pipe with non-condensable gas of the present invention, respectively. like figure 1 and 2 As shown, the heat pipe 1 with noncondensable gas of the present invention is used to dissipate heat from a heat-generating electronic component 2 ; preferably, the heat pipe 1 with noncondensable gas is also combined with a heat sink 3 . In an embodiment of the present invention, the heat sink 3 is a set of heat dissipation fins.

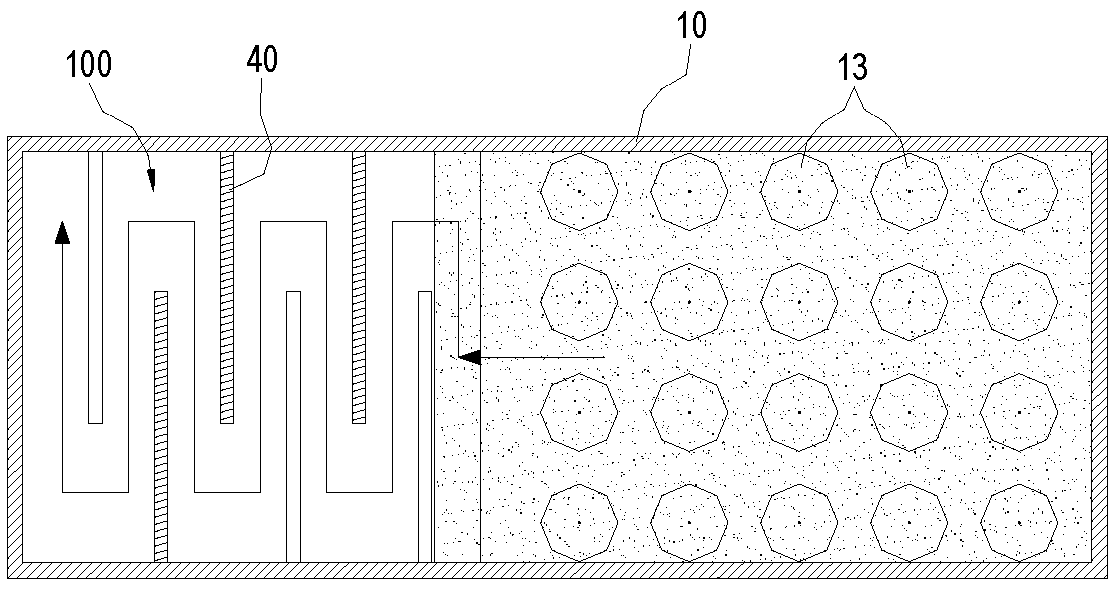

[0016] refer to figure 2 and image 3 As shown, in this embodiment, the heat pipe 1 with noncondensable gas includes a heat con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com