Cold-bending production technology integrated with spraying treatment and cold-bending production line integrated with spraying unit

A production process, cold bending technology, applied in the field of metallurgy, can solve the problems of high cost, large manpower and material resources, etc., to reduce demand, improve production efficiency and production benefits, and reduce the cost of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The on-line cold-bending production process integrated with spraying treatment provided in this embodiment transforms the cold-state strip into a cold-bent component with a specified shape after forming, and performs spraying treatment before the cold-bent component is formed.

[0030] Among them, the spraying process can not only remove rust, oxides and dirt, but also achieve the required uniform roughness under the violent impact and friction of abrasives, expand the physical adsorption of the surface of the material, and enhance The mechanical adhesion between the anti-corrosion layer and the surface of the component. In this embodiment, the sprayed medium can be steel shot or steel grit.

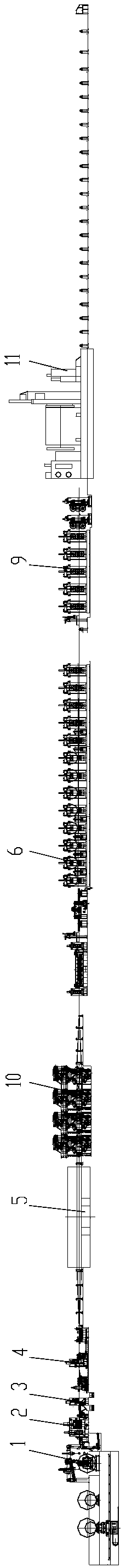

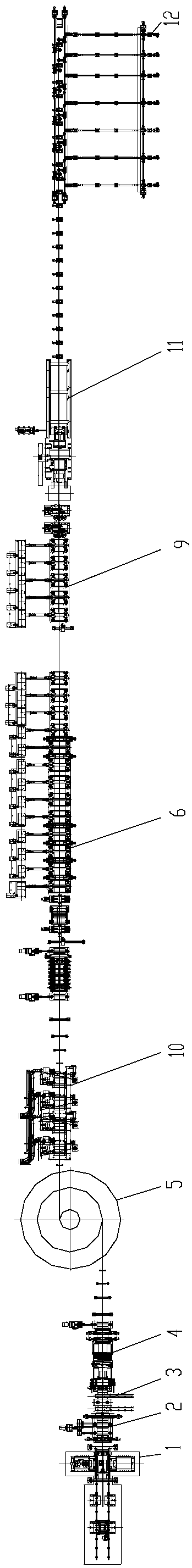

[0031] In this example, see figure 1 , figure 2 First, the cold strip is sent into a spiral looper 5 for storage and feeding, and then, the material supplied by the spiral looper 5 is sprayed first, and then the forming process, sizing and straightening are performed in sequenc...

Embodiment 2

[0044] This embodiment provides an online cold-bending production process with integrated spraying treatment. The difference between the online cold-bending production process with integrated spraying treatment in this embodiment and Embodiment 1 is that the material is sprayed after the cold-bending member is formed. And in this embodiment, the cold-formed member can be either an open profile or a closed profile. The closed profile can be one of square tube, rectangular tube, round tube or other heterosexual tubes.

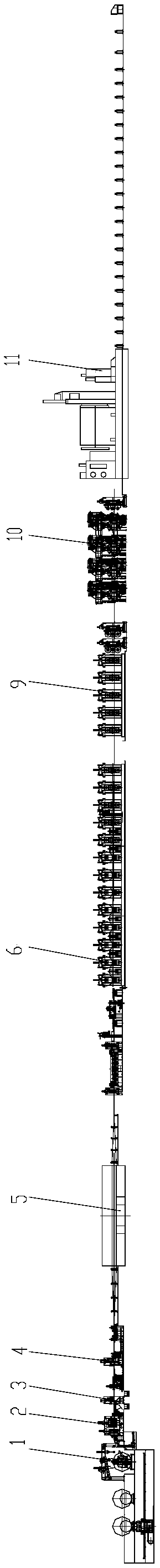

[0045] Specifically, see image 3 , Figure 4 The on-line cold bending process of the integrated spraying treatment in this embodiment includes: sending the cold strip into a spiral looper 5 for storage and feeding, and forming the materials supplied by the spiral looper 5 in sequence After processing and sizing and straightening, spray processing and cutting to length are carried out in sequence.

[0046] This embodiment also provides a continuous cold bendin...

Embodiment 3

[0050] The difference between the on-line cold-bending production process of this embodiment and the second embodiment is that the material needs to be closed-end welding and cooling before being sizing and straightening after forming, and the cold-bending component in this embodiment is Closed profiles, not suitable for open profiles.

[0051] Specifically, see Figure 5 , Figure 6 , the material supplied by the spiral looper 5 is first subjected to forming treatment, closed welding, cooling treatment and sizing and straightening in sequence, and then spraying treatment and cut-to-length cutting in sequence.

[0052] When the cold-formed member is a closed profile, the surface near the junction will inevitably be re-oxidized due to high-frequency welding. The online cold-bending production process integrated with spray treatment in this embodiment not only omits the transition before spray treatment The loading and unloading link of the material, and only one spray treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com