Aircraft engine hanging structure

An aircraft engine and suspension technology, which is applied to aircraft power plants, aircraft parts, power plant construction, etc., can solve the problems of difficult installation coordination, difficult processing, complex structure, etc., and achieve light weight, high structural rigidity, and reduced Effect of Structural Weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

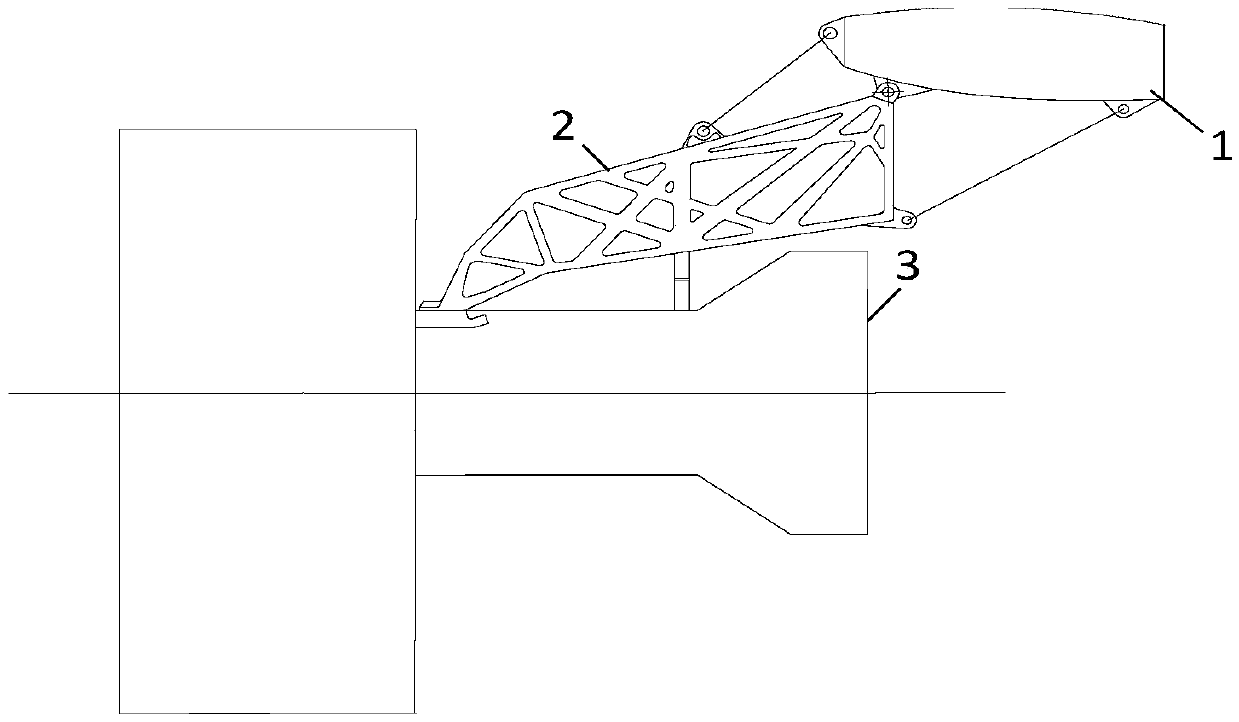

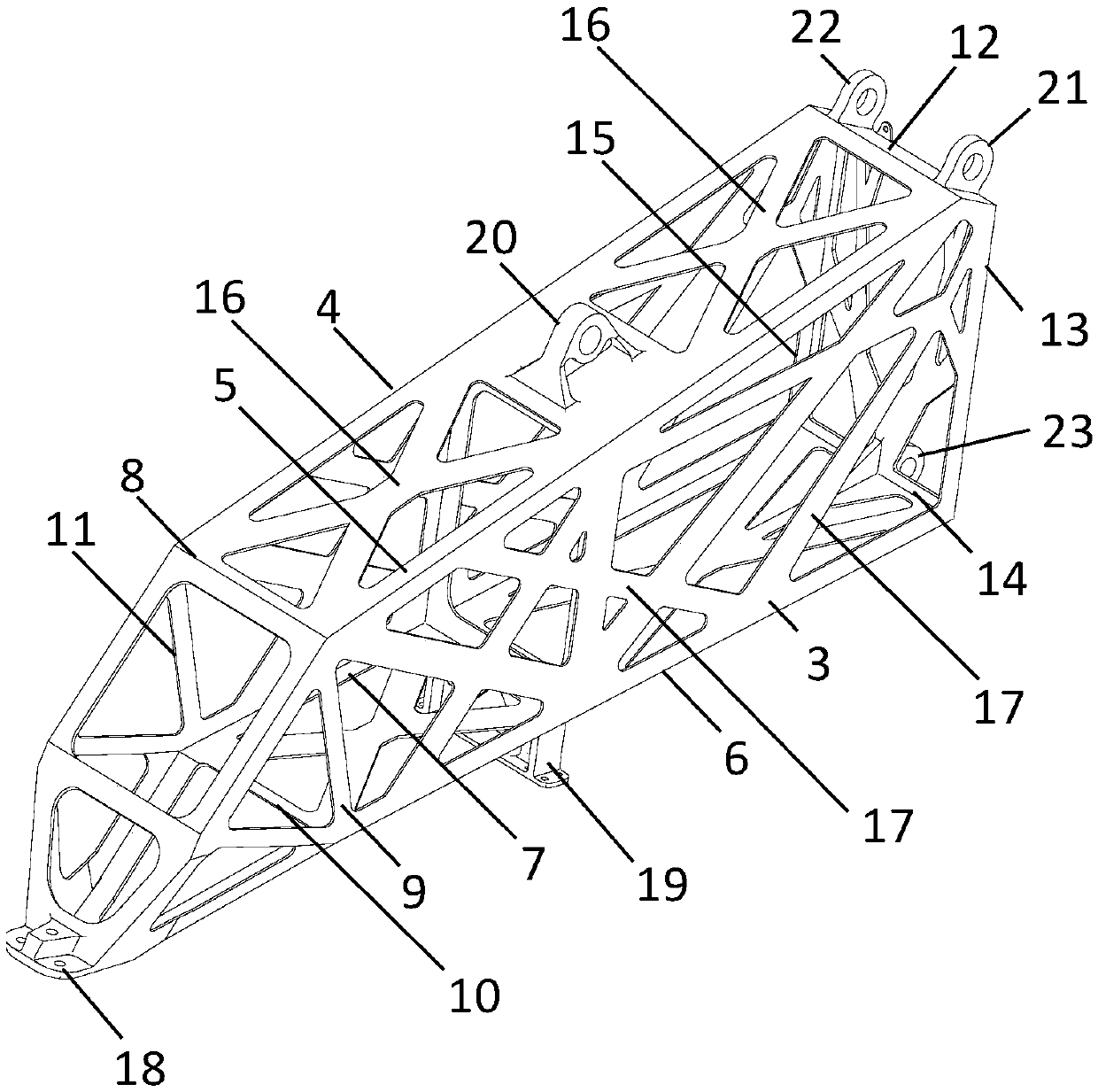

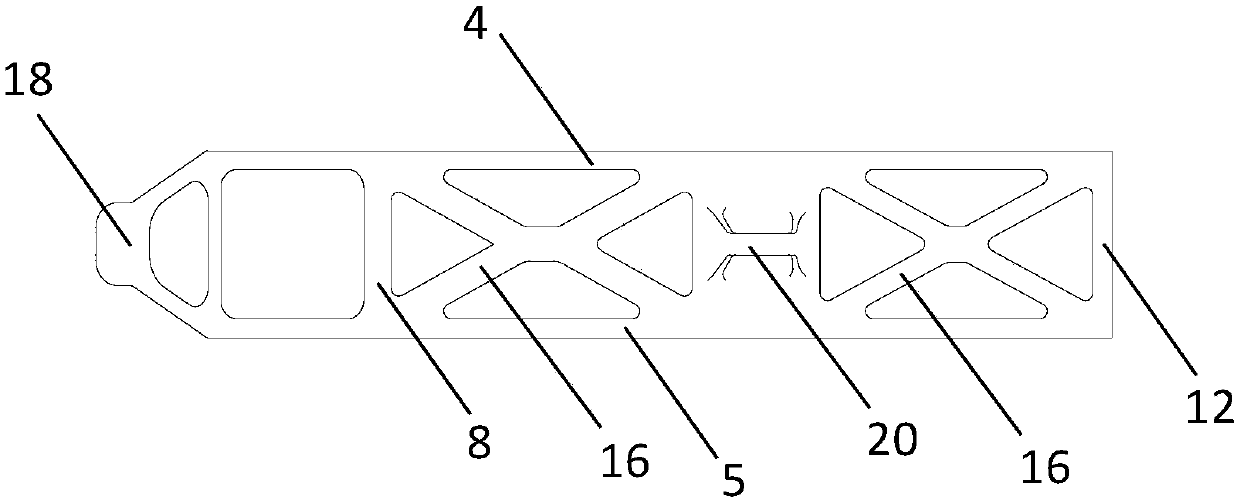

[0014] Referring to the accompanying drawings: the aircraft engine suspending structure of the present application is located below the wing 1, and is used to suspend the engine 3 on the aircraft wing. Therefore, the suspending structure 2 must meet the necessary rigidity and strength, and at the same time try to Possibly reduce own weight. The aircraft engine suspension structure of the present application includes a suspension body and a plurality of joints for connecting with adjacent structures. It is characterized in that the suspension body and the joints are an integral structure of additive manufacturing, and the suspension body 2 is a A hollow truss structure composed of a plurality of edge strips and a plurality of ribs, the edge strips constitute the outline of the hanging body, the ribs are staggered between the edge strips, and the joint base is connected with the adjacent edge strips and ribs . In practice, the outline of the hanging body includes four side edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com