Methylphosphinate-based high-transparency flame-retardant polyvinyl alcohol film and preparation method thereof

A technology of polyvinyl alcohol film and methyl hypophosphorous acid, which is applied in the field of polymer chemistry, can solve the problems of easy change of film properties, lower flame retardant efficiency, unstable film properties, etc., and achieve high transparency retention rate, high resistance High fuel efficiency and high oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Synthesis of MeHP

[0044] Take 1 mol of methyl dichlorophosphine slowly dropwise into 2 mol of water, react at 50°C for 2 hours, and then remove the generated hydrogen chloride gas under reduced pressure to obtain colorless liquid methyl phosphinic acid MeHP.

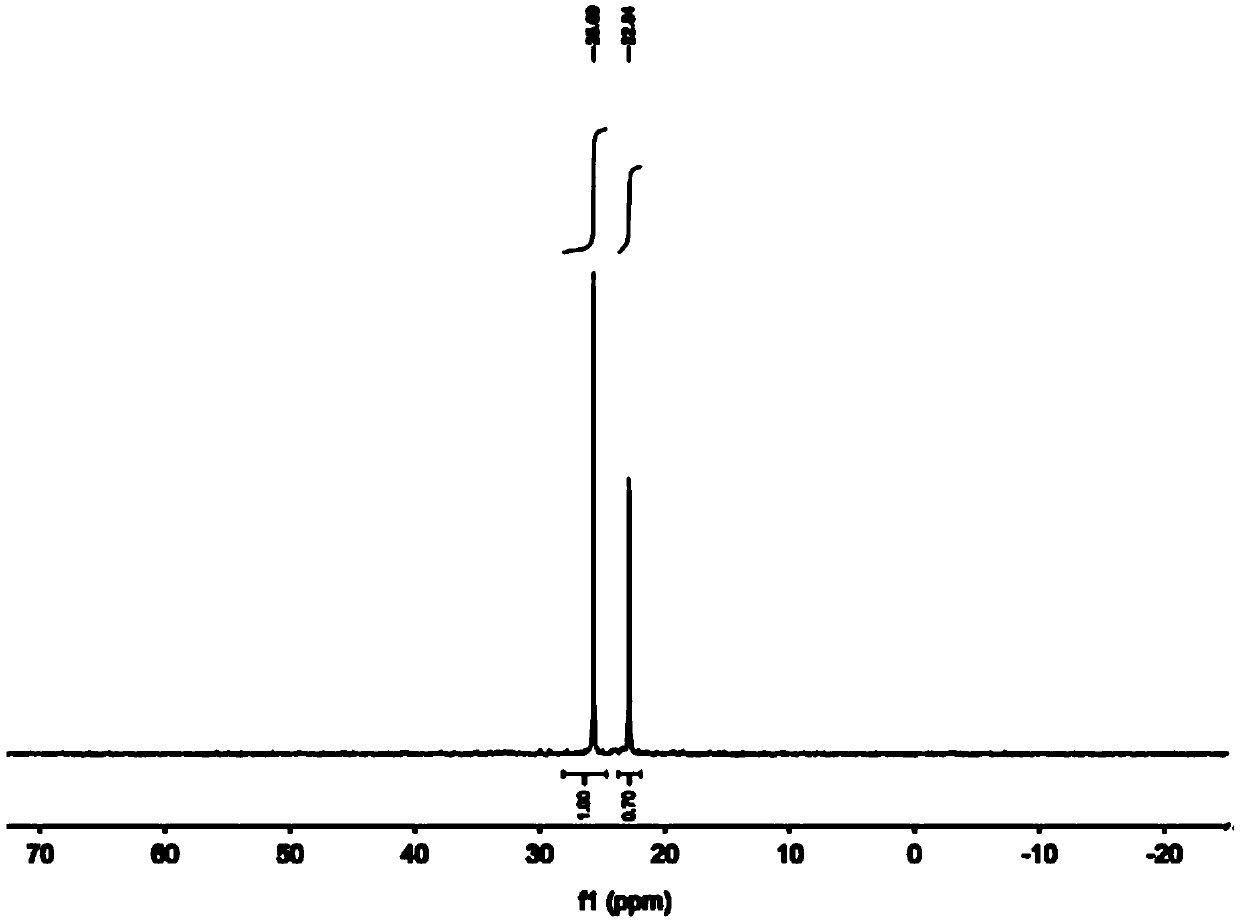

[0045] The structure of MeHP is tested by phosphorus nuclear magnetic resonance analyzer, and the results are as follows: figure 1 shown. MeHP 31 Two P resonance shift peaks (25.68 and 22.83ppm) appeared in the P-NMR spectrum. This is because MeHP has two isomers.

[0046] Preparation of PVA aqueous solution

[0047] Polyvinyl alcohol is dissolved in water, and stirred at 95° C. for 5 hours until the PVA is completely dissolved in water to form a transparent aqueous solution with a mass percentage of PVA of 10%.

Embodiment 2

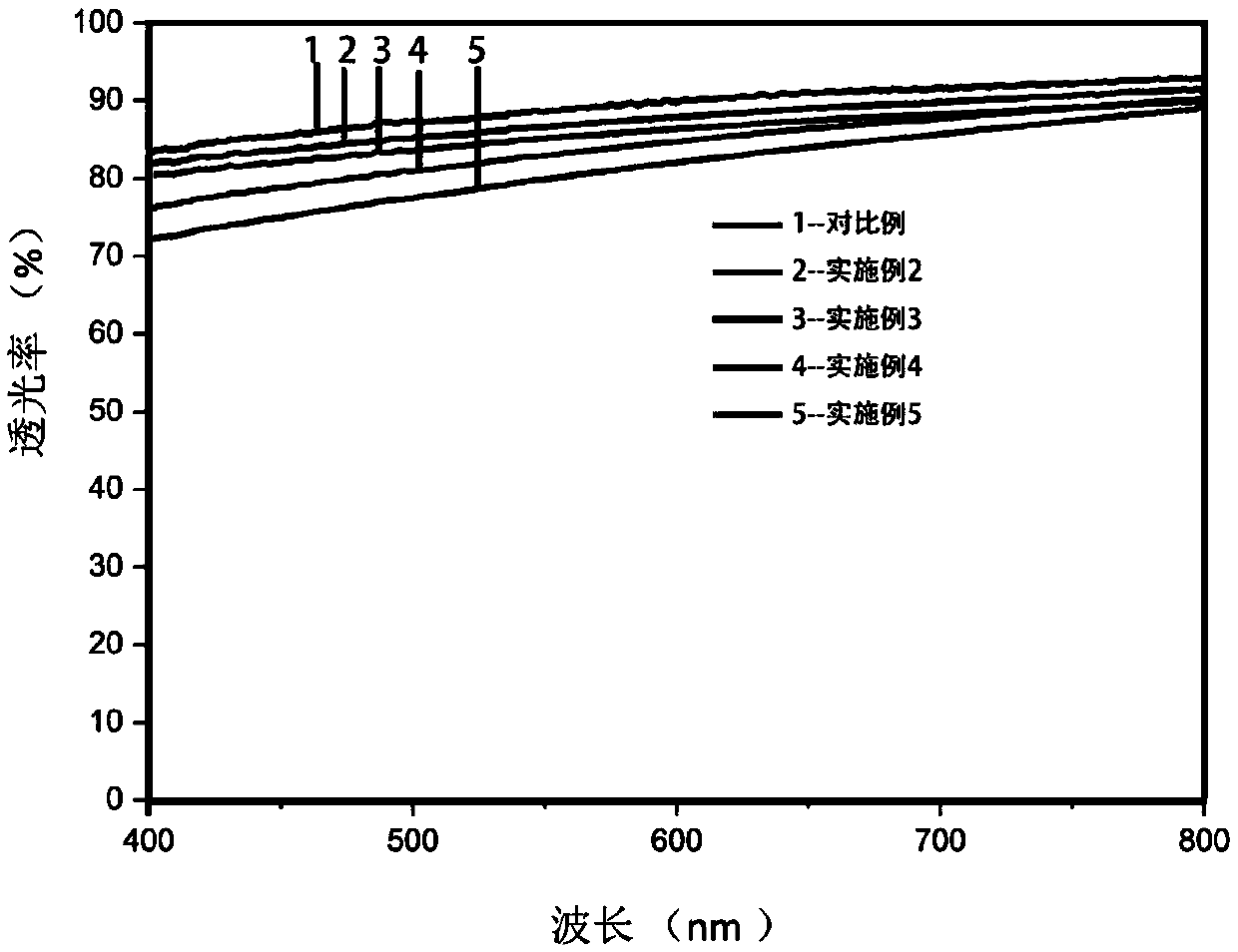

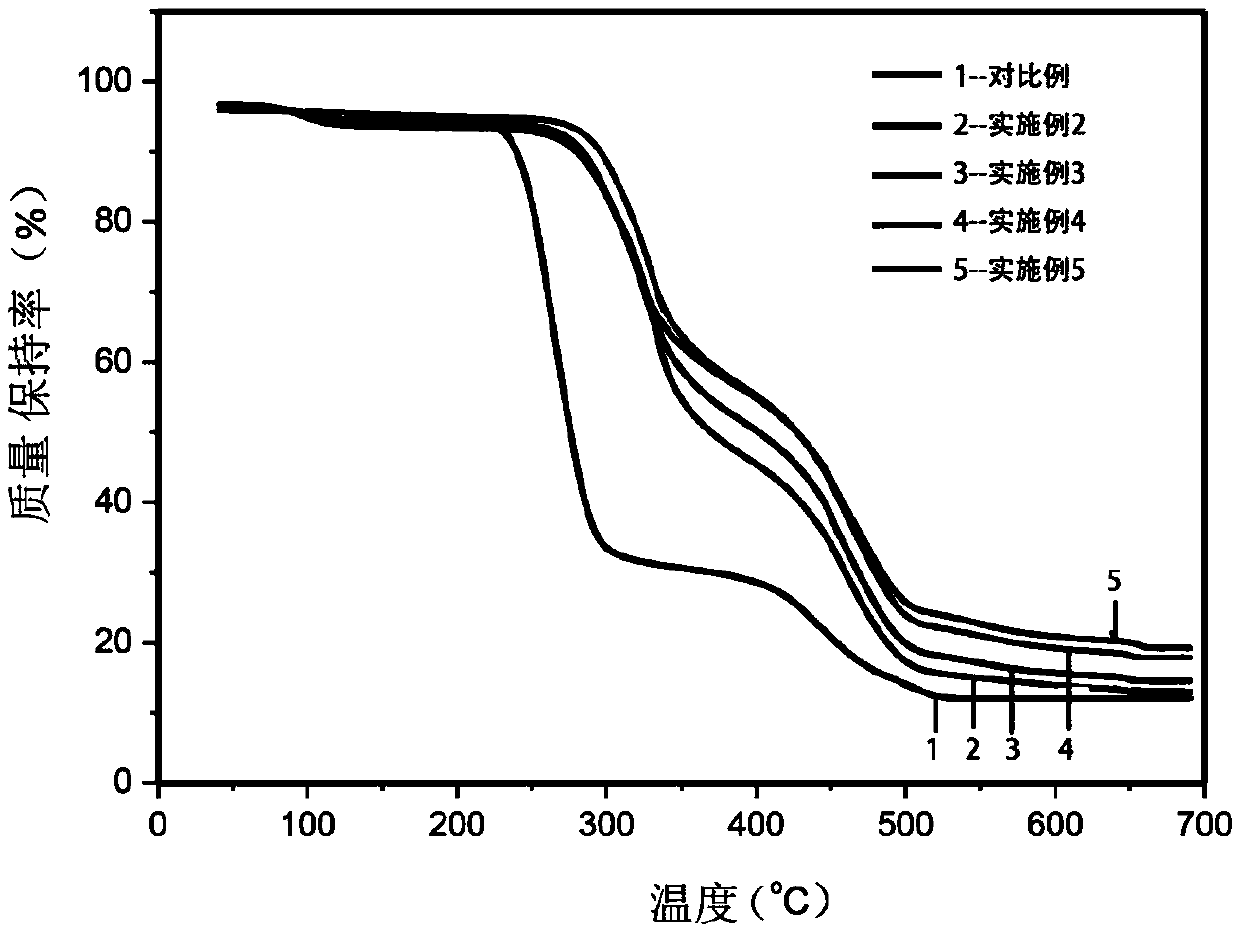

[0049]Take 95g of PVA transparent aqueous solution with a concentration of 10% by mass, add 0.5g of MeHP, and stir mechanically at room temperature for 20min. After mixing evenly, a mixed solution containing MEHP and PVA is obtained, based on the mass sum of MeHP and PVA in the mixed solution , the mass content of MEHP in the mixed solution is 5%. The mixed solution was coated on the substrate, and dried according to the temperature rise program of 50°C / 8hr+100°C / 4hr to obtain a highly transparent flame-retardant PVA film with a film thickness of 200μm.

Embodiment 3

[0051] Get 90g of the PVA transparent aqueous solution with a concentration of 10% by mass, add 1g of MeHP, and mechanically stir for 20min at normal temperature. After mixing evenly, a mixed solution containing MEHP and PVA is obtained. Based on the mass sum of MeHP and PVA in the mixed solution, The mass content of MEHP in the mixed solution is 10%. The mixed solution was coated on the substrate, and dried according to the temperature rise program of 50°C / 8hr+100°C / 4hr to obtain a highly transparent flame-retardant PVA film with a film thickness of 200μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com