Partial prefabricated assembled steel and recycled concrete composite panel and its production and assembly method

A technology of recycled concrete and prefabricated assembly, applied in construction, building components, building materials, etc., can solve the problems of complex construction and poor adhesion of shear connectors, and achieve fast assembly methods, strong anti-slip ability, and high production simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

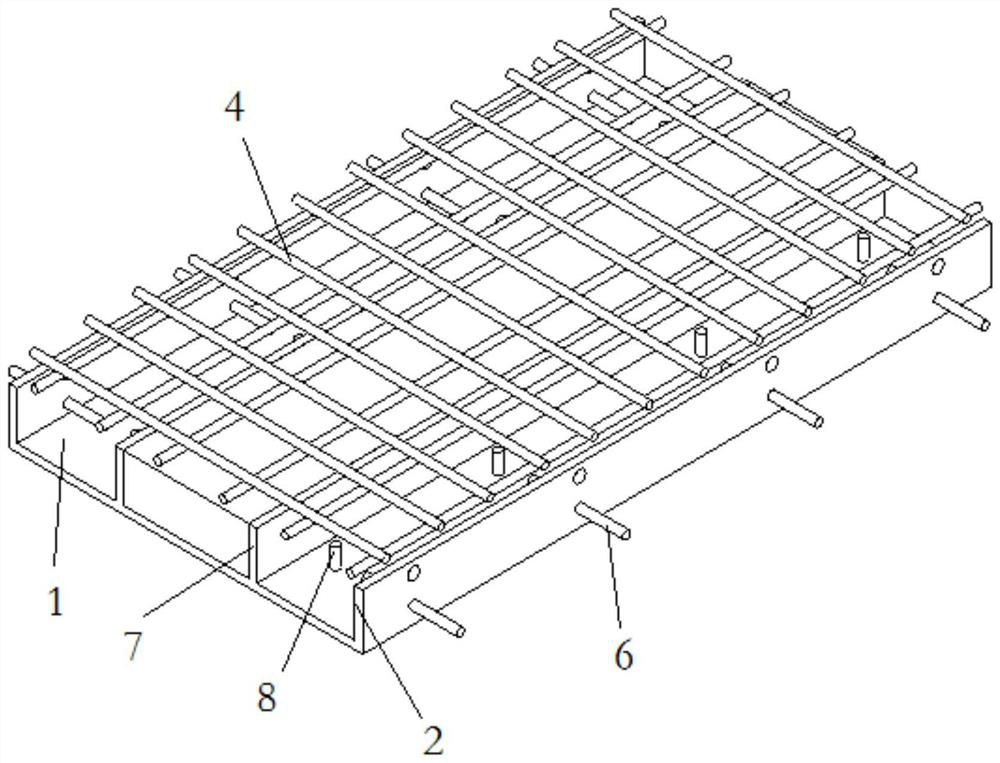

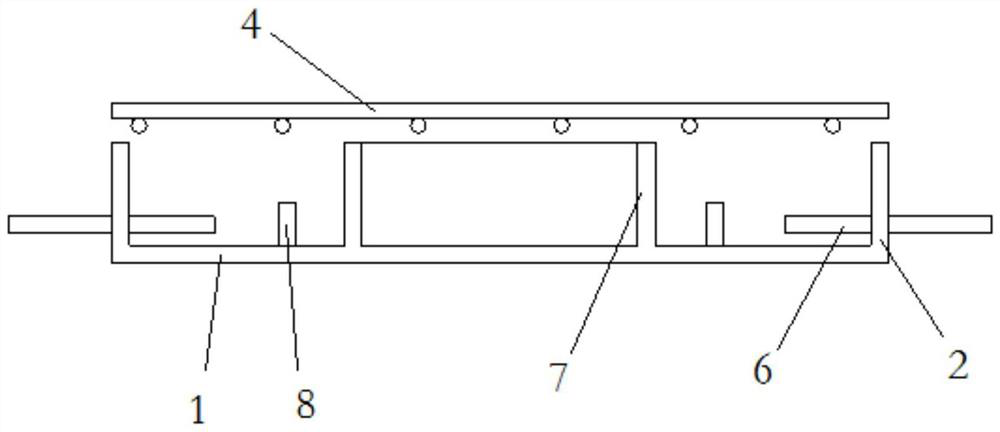

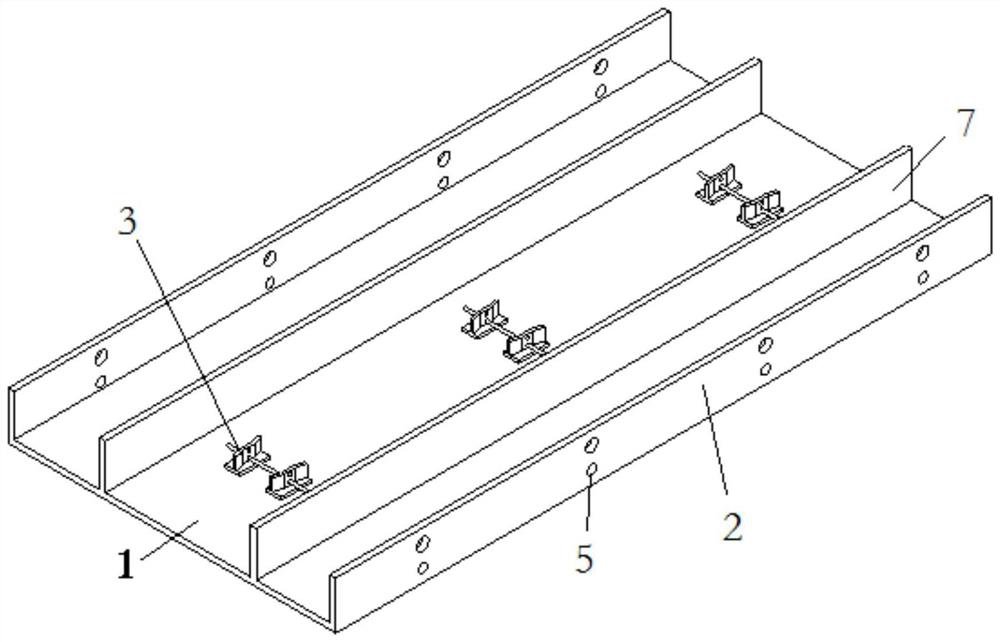

[0032] A partially prefabricated steel and recycled concrete composite panel, such as figure 1 , figure 2 and image 3 As shown, it includes a composite plate bottom plate 1, two side plates 2 and a plurality of ribs 7 are vertically fixed on the composite plate bottom plate 1, each side plate 2 and each rib 7 are arranged in parallel, and the ribs 7 are located at Between the two side plates 2, any two adjacent rib plates 7 are fixed with shear connectors 3 on the bottom plate 1 of the connecting plate, such as Figure 4 As shown, each shear connector 3 includes a bottom plate 3-1, a connecting plate 3-2 and two inclined plates 3-3 are vertically fixed on the bottom plate 3-1, and one inclined plate 3-3 and the connecting plate 3 One side of -2 is affixed, and the other sloping plate 3-3 is affixed to the other side of the connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com