Full-automatic wet spraying control method and full-automatic wet spraying system

A control method and fully automatic technology, which is applied in earthwork drilling, spraying devices, wellbore lining, etc., can solve the problems of difficult control of wet spraying quality, low safety, and low work efficiency, so as to achieve automatic and efficient spraying process and improve spraying Quality, the effect of reducing skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

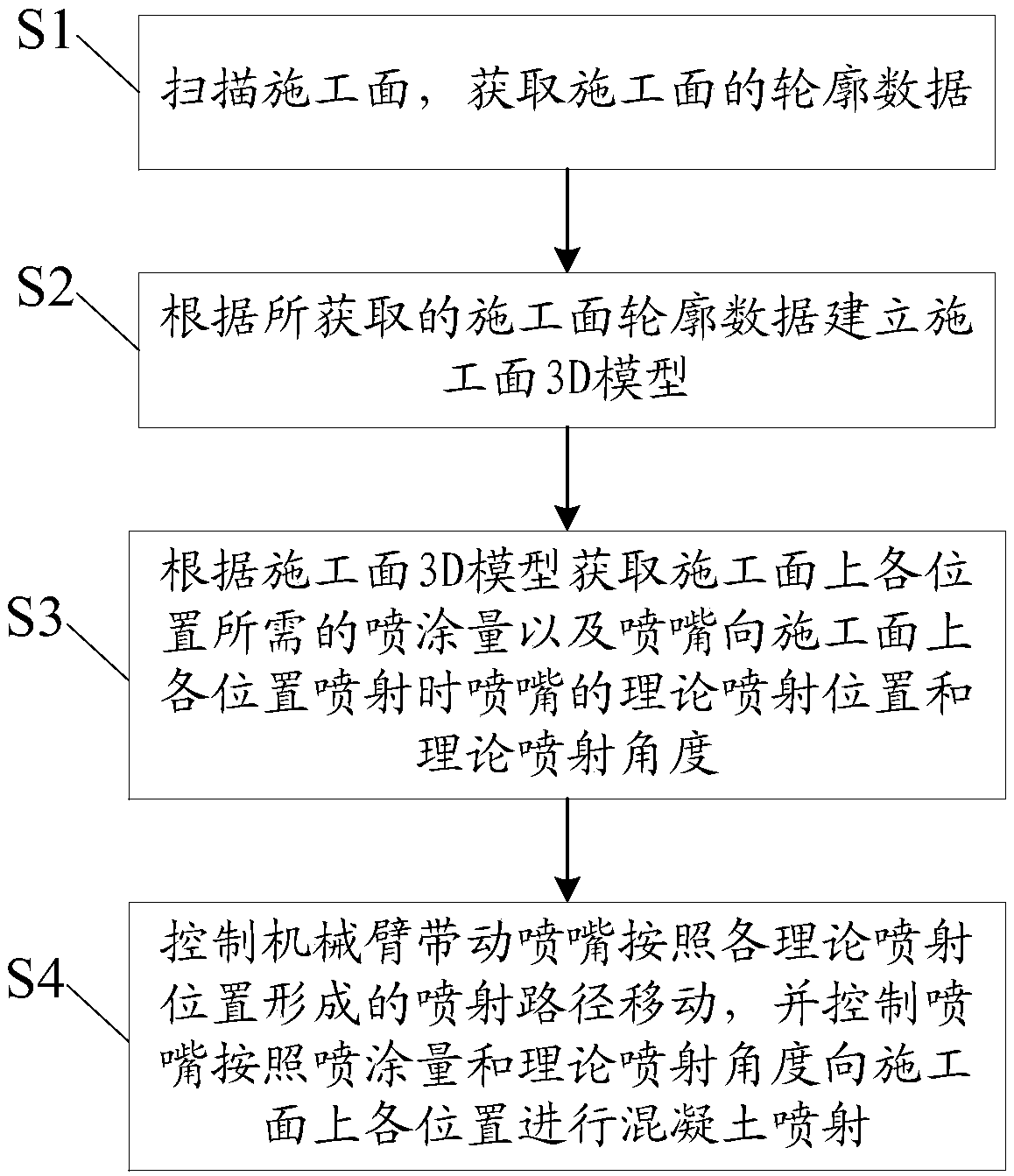

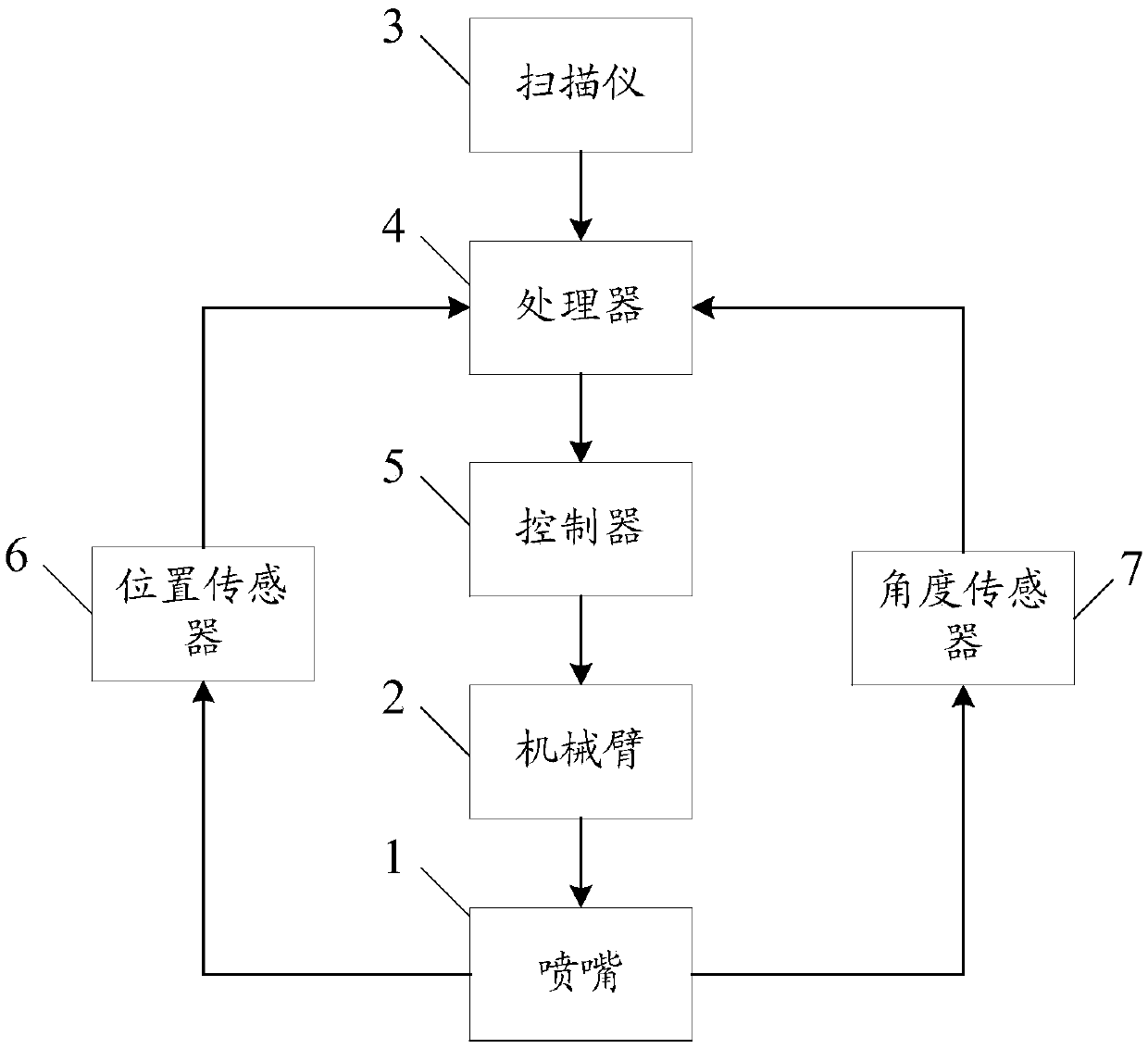

[0037] The core of the present invention is to provide a fully automatic wet spray control method and a fully automatic wet spray system, which scans the construction surface and models the construction surface, uses the 3D model of the construction surface to obtain the spraying motion parameters of the mechanical arm and the nozzle, and controls The mechanical arm and the nozzle automatically move according to the motion parameters to complete the spraying operation on the construction surface, saving time and effort, with high spraying quality and high safety.

[0038] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] Please refer to figure 1 and figure 2 , figure 1 It is a schematic flow chart of a specific embodiment of the fully automatic wet spray control method provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com