An integrated cooker with oil fume adaptability

A technology of integrated stoves and performance, applied in the field of integrated stoves, can solve the problems of oil stains not easy to wipe, increase production costs, hidden safety hazards, etc., achieve the effects of reducing production costs and power consumption, increasing fan power, and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

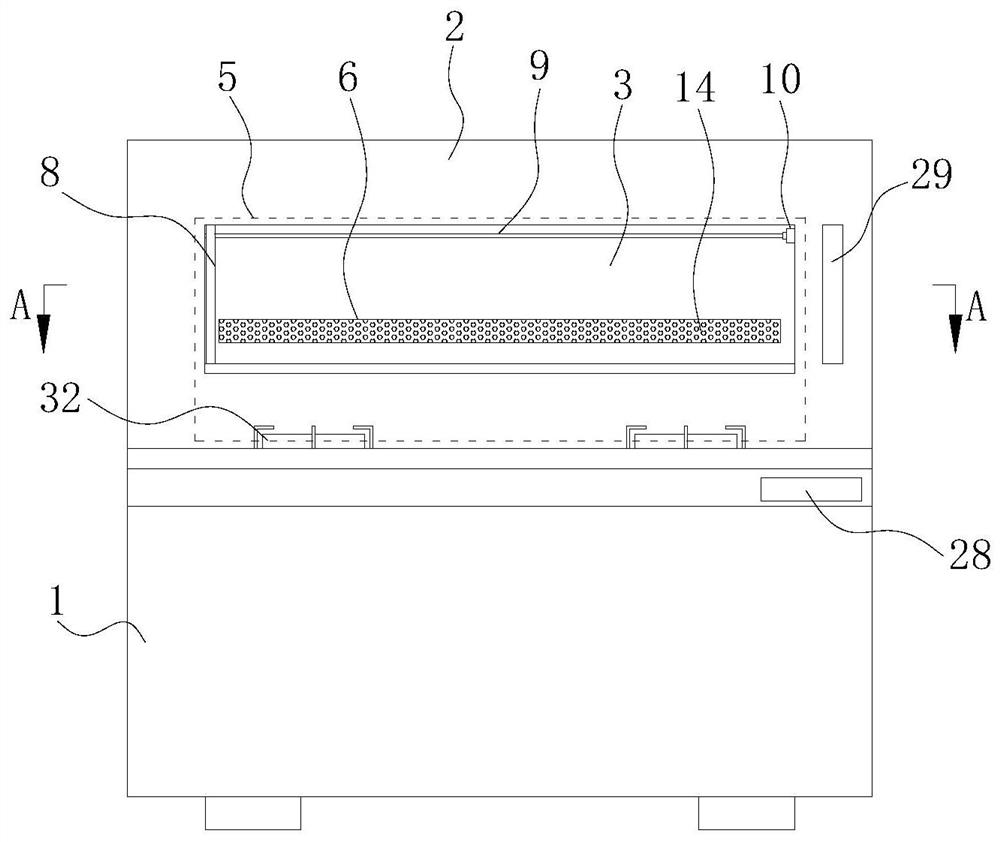

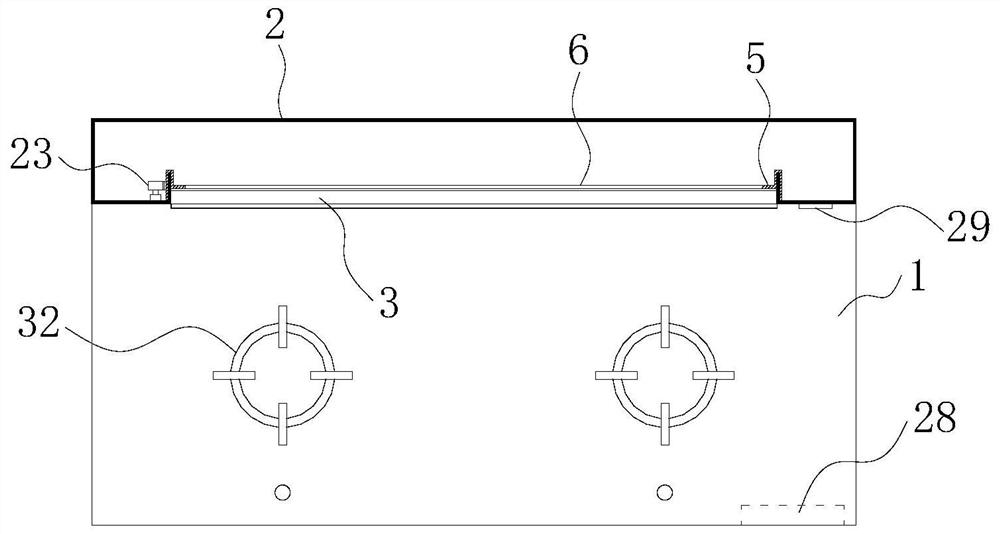

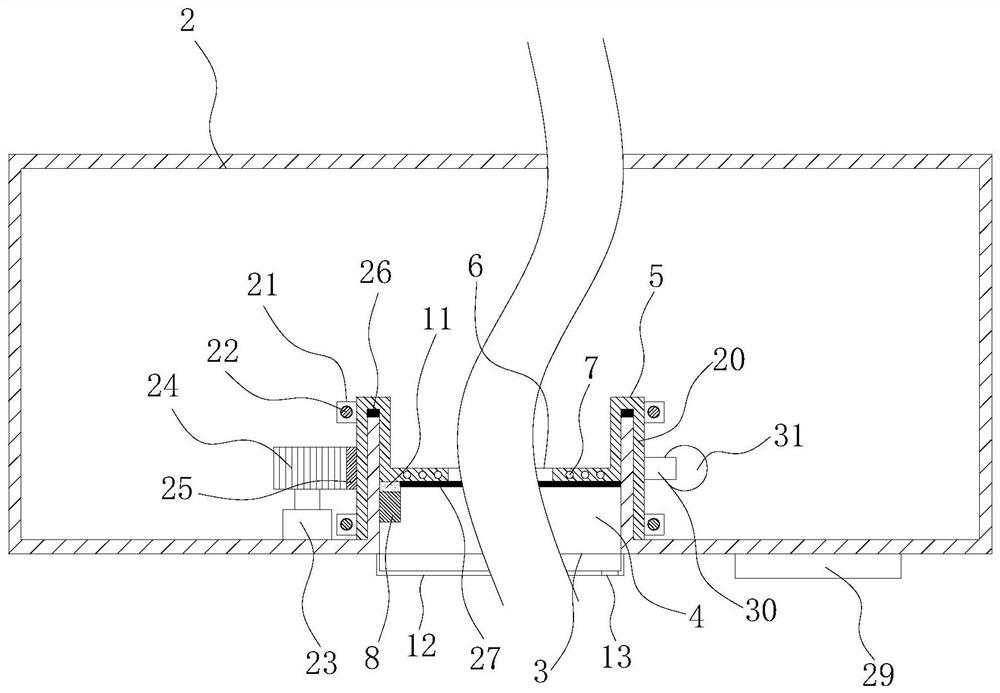

[0026] like Figure 1-8 The shown integrated cooker with cooking fume adaptability includes an integrated cooker main body 1 and a hollow smoke collecting hood 2 arranged on the rear side of the top of the integrated cooker main body 1. Fans, exhaust ducts, etc. are connected to discharge oily fume. Compared with the traditional integrated cooker, one of the core improvements of the present invention is that, as figure 1 As shown, the center of the front panel of the smoke collecting hood 2 is provided with a rectangular adjustment opening 3 , and the edges around the adjustment opening 3 are bent backward to form a rectangular smoke inlet passage 4 . The rear end of the smoke inlet channel 4 is provided with a lifting plate 5 , and the middle part of the lifting plate 5 is provided with a strip-shaped smoke inlet 6 extending along the left and right directions. The front side of the lifting plate 5 is close to the edge of the rear end of the smoke inlet passage 4, and can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com