Water seal friction torque detection machine

A friction torque, testing machine technology, used in measuring devices, torque measurement, power measurement and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

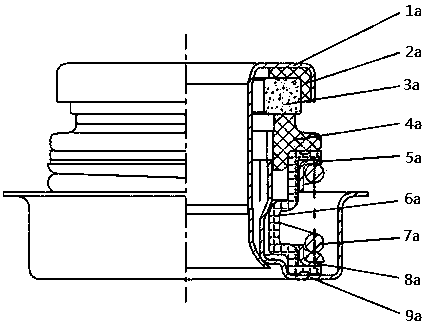

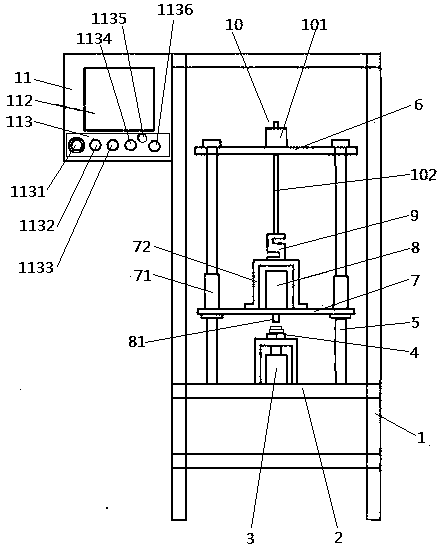

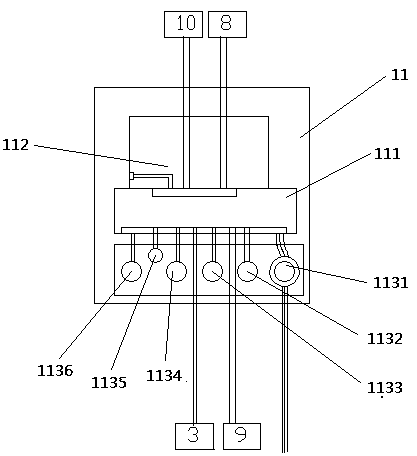

[0053] Embodiment 1: A water seal friction torque detector, see figure 2 , including a support frame 1, a support platform 2, a torque sensor 3, a water seal mounting seat 4, a vertical shaft 5, a fixed beam 6 and a movable beam 7, a servo motor 8, a pressure sensor 9, a lifting device 10 and a console 11; The middle part of the support frame 1 is fixedly equipped with a horizontally distributed support platform 2, and a vertically distributed torque sensor 3 is installed above the central part of the support platform 2. The upper end of the torque sensor 3 is a torque input shaft end. The upper end of the torque sensor 3 is fixedly installed with a horizontally distributed water seal mounting seat 4;

[0054] A pair of vertical shafts 5 are mounted symmetrically on both sides of the support platform 2, and horizontally distributed fixed crossbeams 6 are fixedly mounted on the tops of the two vertical shafts 5, and the two ends of the fixed crossbeams 6 are fixed on two The ...

Embodiment 2

[0074] Embodiment 2: The difference from Embodiment 1 is that the lifting device 10 is a manual screw lift.

Embodiment 3

[0075] Embodiment three: the difference from embodiment one is: as Figure 5 As shown, the motor output shaft 81 is connected with a shaft coupling 82 and a driven shaft 83, and the shaft coupling 82 is a flexible shaft coupling; through this structure, the servo motor 8 can be better protected to prevent the servo motor from 8 Overload operation, and the detection of different types of water seals can be realized by changing the size and model of the coupling 82 and the driven shaft 83.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com