Overload protection device of torque driver

An overload protection and driver technology, applied in the field of drivers, can solve the problems of complex structure, damage to other components by debris, and difficulty in removing small debris, and achieve the effects of compact overall structure, convenient manufacturing and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

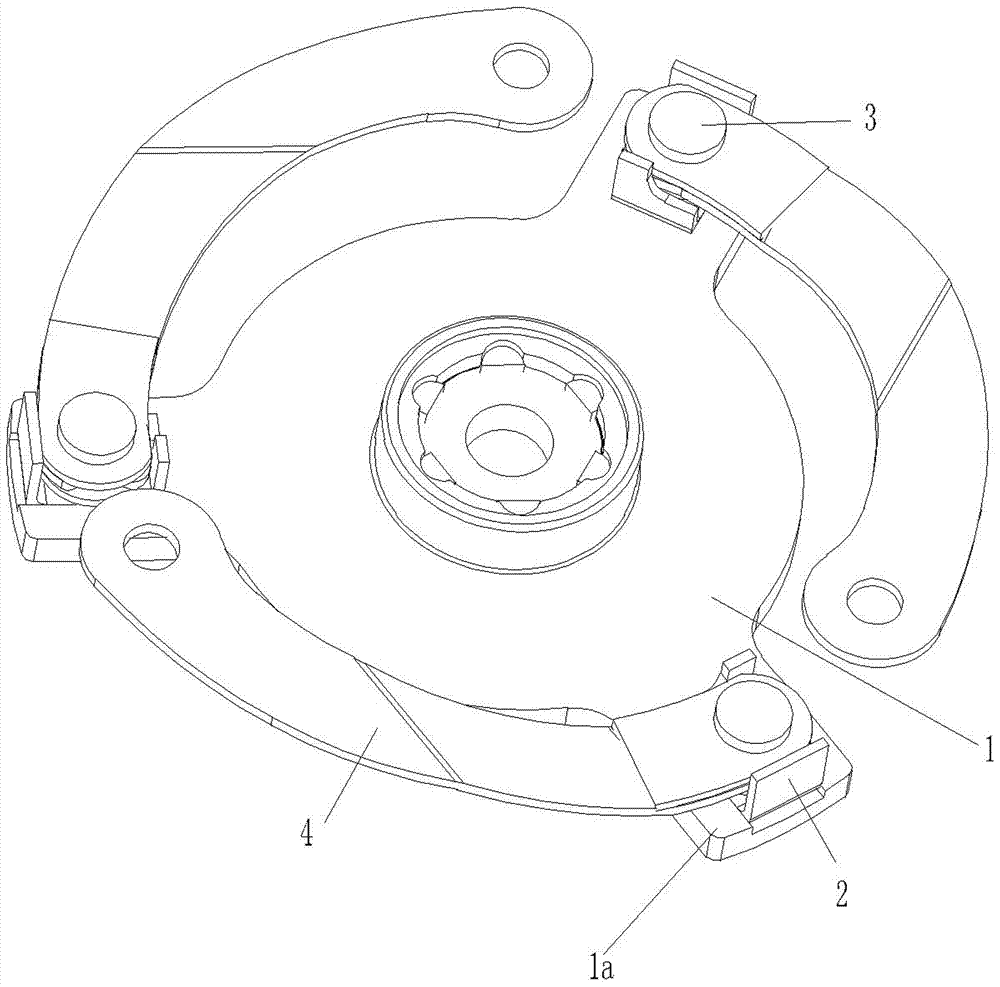

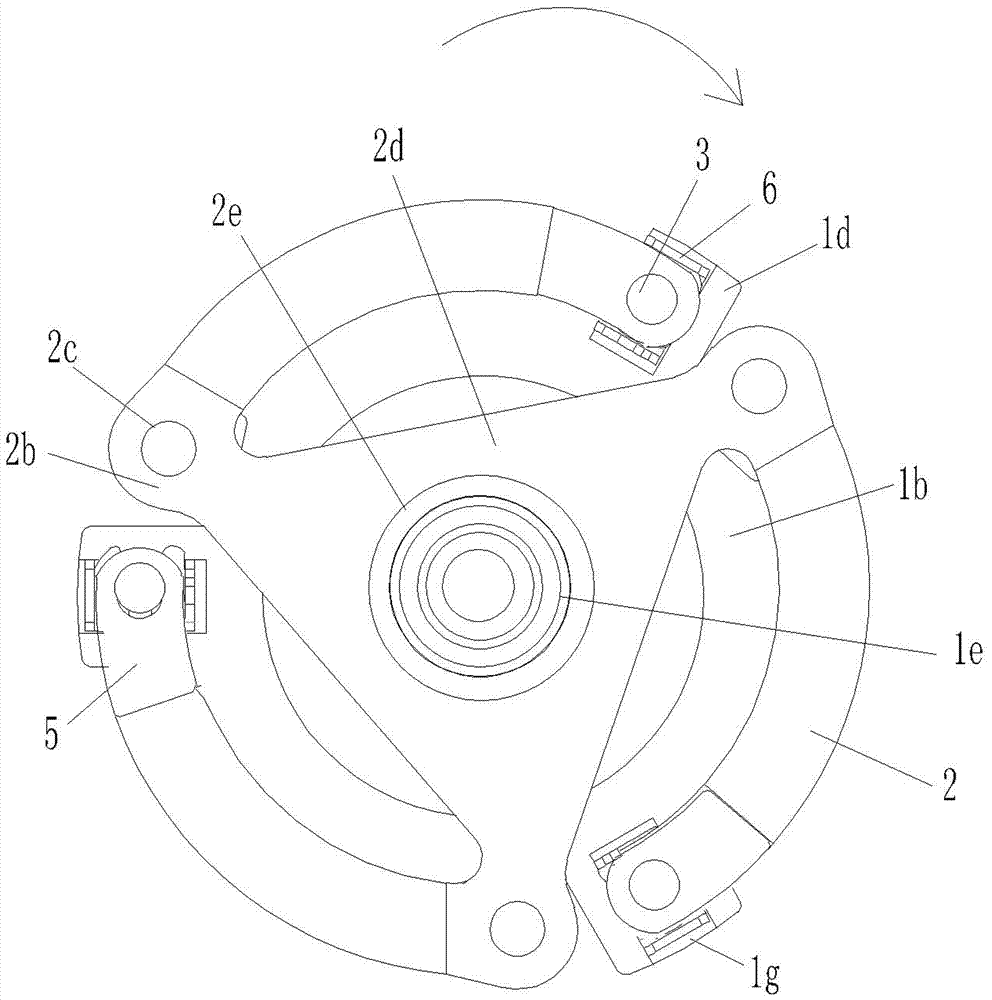

[0027] Such as figure 1 , 2 , 8 and 9, an overload protection device for a torque driver, which includes a figure keyboard 1 and a group of connected arc reeds 2, one end of each arc reed 2 is provided with a snap-in gap 4, The other end is provided with a connecting part 2b that is connected and matched with the pulley, and the end where the snap-in notch 4 is located is not on the same level as the end where the connecting part 2b is located, so that the arc-shaped reed 2 has a Elasticity in direction. The spline key 1 is composed of a connection plate 1b and its connected spline sleeve 1e, and a central gasket 8 is also provided in the spline sleeve 1e, and the spline sleeve 1e forms a connection with the compressor .

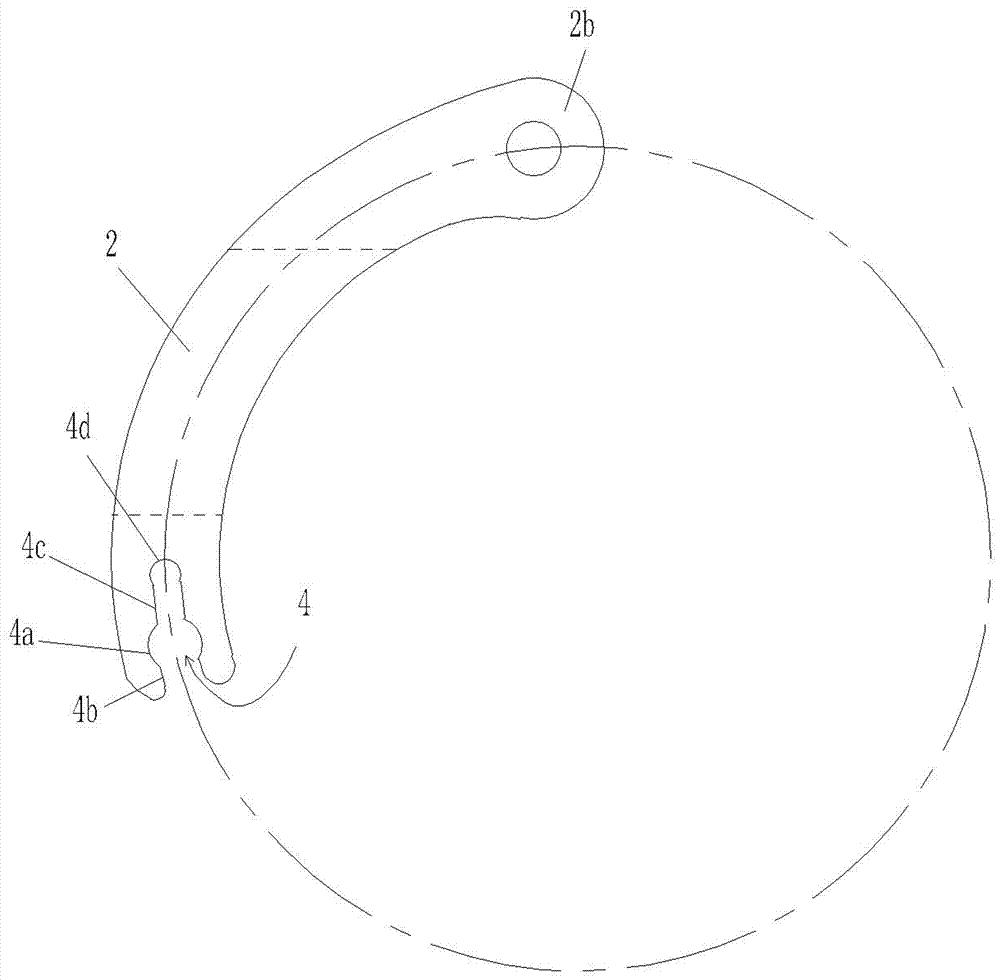

[0028] The radian of the clamping notch 4 is the same as that of the arc-shaped reed 2, and it includes: a clamping hole 4a corresponding to the rivet 3, and a clamping gap 4b communicating with the outside is provided on one side of the clamping hole 4a....

Embodiment 2

[0035] Such as Figure 3-9 As shown, an overload protection device for a torque driver, it includes a figure keyboard 1, and a group of three arc-shaped reeds 2, each end of one end of the arc-shaped reed 2 is provided with a snap-in gap 4, and the other end of the The end portion is provided with a connecting portion 2b that is connected and matched with the pulley, and the arc-shaped reed 2 is connected to the pulley by passing a bolt not shown in the figure through the connecting hole 2c on the connecting portion 2b. The end where the locking notch 4 is located is not on the same level as the end where the connecting portion 2 b is located, so that the arc-shaped reed 2 has elasticity along the axial direction of the keypad 1 .

[0036] The spline key 1 includes a spline sleeve 1e, and a central gasket 8 is arranged inside the spline sleeve 1e, and the spline sleeve 1e forms a connection and fit with the compressor. One end of the spline sleeve 1e is connected to the splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com