Detachable pre-cutting stirrer

A mixer and pre-cutting technology, which is applied to mixer accessories, mixers with rotating mixing devices, and pretreatment of mixed materials. It can solve the problems of large loads of mixing blades, non-replaceable disassembly, and economic losses, etc., and achieves reductions in cloth. average, prolong service life, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

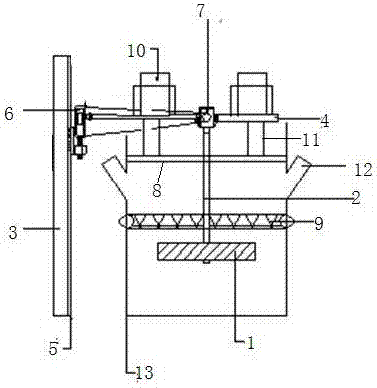

[0017] Embodiment 1: see Figure 1-Figure 2 , a detachable pre-cut agitator, the detachable pre-cut agitator includes a stirring tank 13, a stirring assembly, a support assembly, a cutting and pressing assembly and a power assembly, and the stirring assembly is located in the stirring tank 13; the power The component is located on the supporting component and connected with the stirring component through the stirring drive shaft, the power system of the cutting and pressing component is located on the supporting component, and the pressure plate of the cutting and pressing component is located inside the tank. Both the cutting and pressing assembly and the stirring assembly are placed on the same support assembly, which makes the structure simple and compact, and stands upright in production. The stirring assembly includes a stirring blade set and a transmission shaft. The stirring blade set 1 is connected to the transmission shaft 2 through self-tightening bolts , the support...

Embodiment 2

[0018] Example 2: see Figure 1-Figure 2 , as an improvement of the present invention, the power assembly includes a motor 6 and a reduction box 7, the motor 6 is arranged on the motor running track 5; the reduction box 7 is arranged on the suspension bracket 4, and the motor is connected to the The reduction box is connected, and the belt transmission method is adopted, which can greatly reduce the damage to the mechanical structure of the supporting components caused by the resonance generated when the agitator is working, thereby prolonging the service life of the agitator. The belt drive also has the characteristics of stable output power, and can also protect the motor from overload.

Embodiment 3

[0019] Embodiment 3: see Figure 1-Figure 2 , as an improvement of the present invention, the cutting and pressing assembly includes a solid pressing plate 8, a steel tread plate 9, a hydraulic press 10, and a hydraulic rod 11; the hydraulic press is located above the suspension bracket; the two ends of the hydraulic rod are respectively connected to a solid pressing plate and a hydraulic press; the steel checkered bottom plate is located below the feed inlet, and is connected with the inner wall of the mixing tank by a movable buckle. The steel checkered bottom plate is connected with the inner wall of the mixing tank by movable buckles. When the mixer does not need prefabricated cutting and pressing, the movable buckle can be released, and the steel checkered bottom plate leaves the mixing tank with the mixing blade set. The hydraulic machine of this product adopts independent power supply, which is convenient for maintenance and repair in the production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com