Method for producing quick-frozen steamed cooked wheaten food

A production method and pasta technology, applied in the field of quick-frozen food processing, can solve the problems of short microwave time, dry and hard dough, loss of soft taste characteristics, etc., and achieve the effect of real taste, soft and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

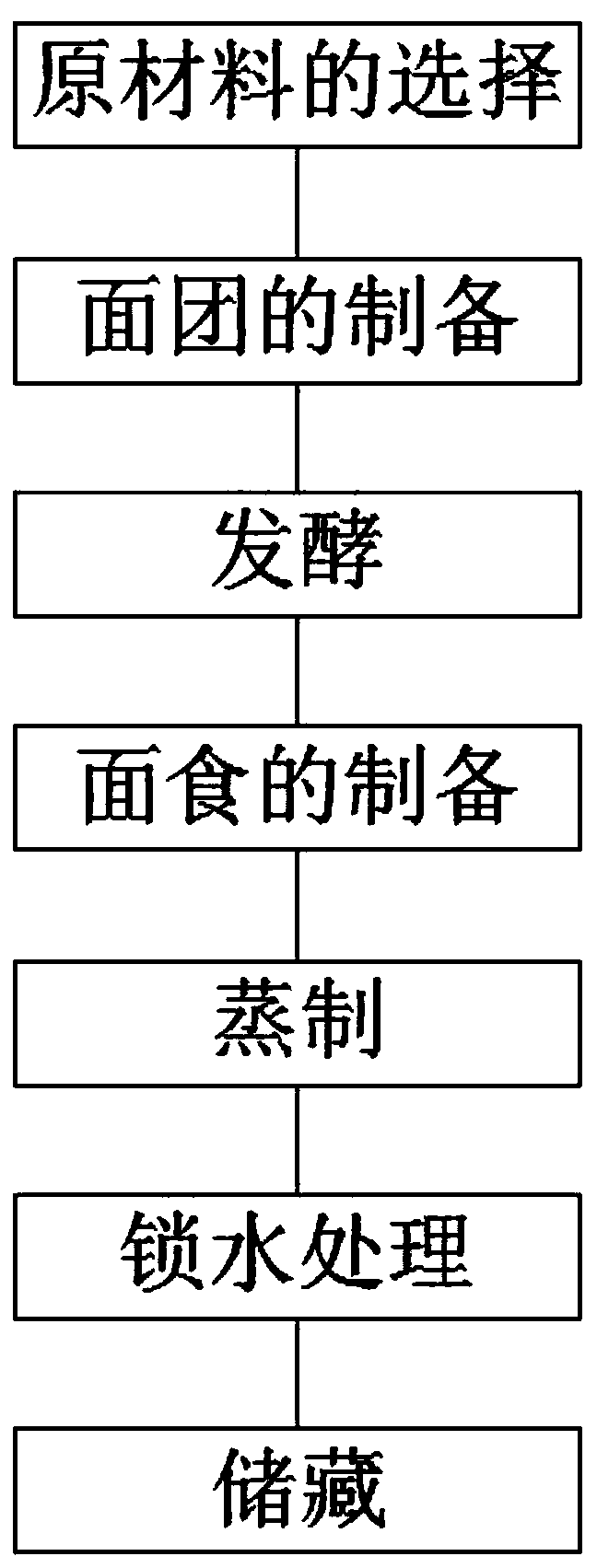

[0024] A production method of quick-frozen steamed pasta, through the steps of selection of raw materials, preparation of dough, fermentation, preparation of pasta, steaming, water-locking treatment and storage, to complete the production of quick-frozen steamed pasta; the specific steps are as follows:

[0025] (1) Selection of raw materials: select 90 parts of cereal powder, 40 parts of drinking water, 1 part of yeast and 0.2 part of additives as raw materials; additives are 20 parts by weight of acetylated distarch phosphate, 10 parts by weight of emulsifier, 4 parts by weight of Thickener, 10 parts by weight of phosphate and 2 parts by weight of gluten-increasing agent, emulsifier is selected from a kind of in propylene glycol fatty acid, diacetyl tartrate glyceride, lecithin; Thickener is selected from xanthan gum, locust bean gum, guar gum , carrageenan, and konjac gum; the gluten-enhancing agent is selected from one of potassium bromate, calcium bromate, and glutinous ri...

Embodiment 2

[0033] A production method of quick-frozen steamed pasta, through the steps of selection of raw materials, preparation of dough, fermentation, preparation of pasta, steaming, water-locking treatment and storage, to complete the production of quick-frozen steamed pasta; the specific steps are as follows:

[0034] (1) Selection of raw materials: select 110 parts of cereal flour, 60 parts of drinking water, 3 parts of yeast and 0.6 part of additives as raw materials; additives are 30 parts by weight of acetylated distarch phosphate, 14 parts by weight of emulsifier, 6 parts by weight of Thickener, 20 parts by weight of phosphate and 4 parts by weight of gluten-increasing agent, the emulsifier is selected from a kind of in propylene glycol fatty acid, diacetyl tartrate glyceride, lecithin; Thickener is selected from xanthan gum, locust bean gum, guar gum , carrageenan, and konjac gum; the gluten-enhancing agent is selected from one of potassium bromate, calcium bromate, and glutino...

Embodiment 3

[0042] A production method of quick-frozen steamed pasta, through the steps of selection of raw materials, preparation of dough, fermentation, preparation of pasta, steaming, water-locking treatment and storage, to complete the production of quick-frozen steamed pasta; the specific steps are as follows:

[0043] (1) Selection of raw materials: select 100 parts of cereal flour, 50 parts of drinking water, 2 parts of yeast and 0.4 part of additives as raw materials; additives are 25 parts by weight of acetylated distarch phosphate, 12 parts by weight of emulsifier, 5 parts by weight of Thickener, 15 parts by weight of phosphate and 3 parts by weight of gluten-increasing agent, the emulsifier is selected from one of propylene glycol fatty acid, diacetyl tartaric acid glyceride, lecithin; the thickener is selected from xanthan gum, locust bean gum, guar gum , carrageenan, and konjac gum; the gluten-enhancing agent is selected from one of potassium bromate, calcium bromate, and glut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com