Method and device for the manufacture of scrubbing brushes and/or painting brushes

A brush and brush technology, applied in the direction of brush type, brush body, application, etc., can solve problems such as complex structure, achieve the effect of simple structure, omit dynamic movable parts and cables, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

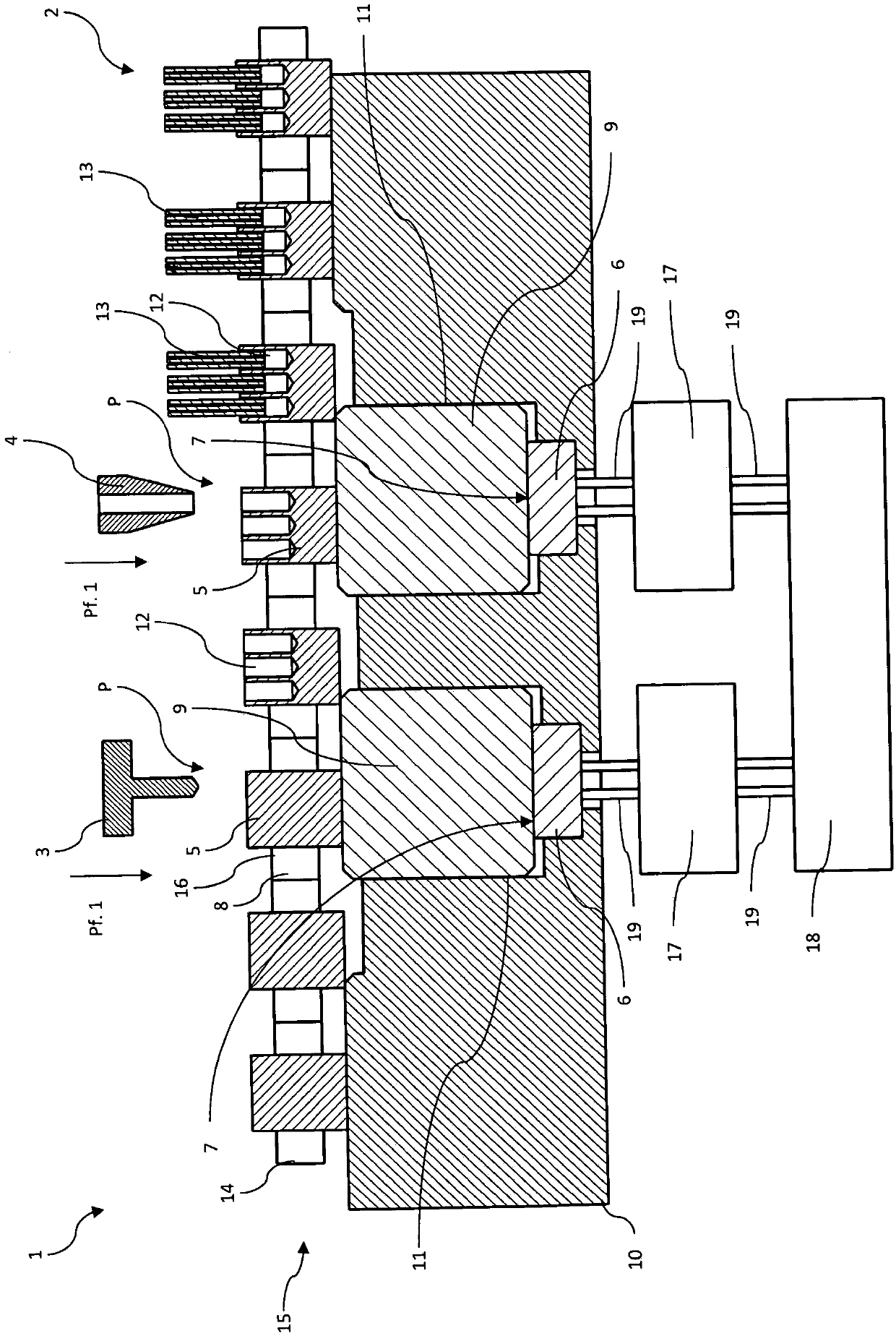

[0029] The single figure shows a device for producing brushes and / or brushes 2 , which is designated as a whole by the reference number 1 . The device 1 shown in the drawing comprises a total of two machining tools 3 and 4 , the first machining tool being designed as a drill 3 and the second machining tool being designed as a plugging tool 4 . The two processing tools 3 , 4 are designed for processing the bristle carrier 5 of the brush 2 to be produced.

[0030] A pressure sensor 6 is assigned to each processing tool 3 , 4 of the device 1 . Each pressure sensor 6 has a pressure-receiving surface 7 and is designed to determine the processing pressure exerted by the corresponding processing tool 4 of the device 1 on the bristle carrier 5 .

[0031] The pressure receiving surface 7 of the pressure sensor 6 is arranged behind the bristle carrier 5 in the processing position P in the working direction Pf.1 of the respective processing tool 3 , 4 . The processing positions P are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com