Equipment for automatically mixing liquid drink freshly and mixing method

A beverage and automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of many operations, waste, time-consuming and labor-intensive, etc., and achieve the effect of improving economic efficiency, speeding up preparation time, and automatically cleaning equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

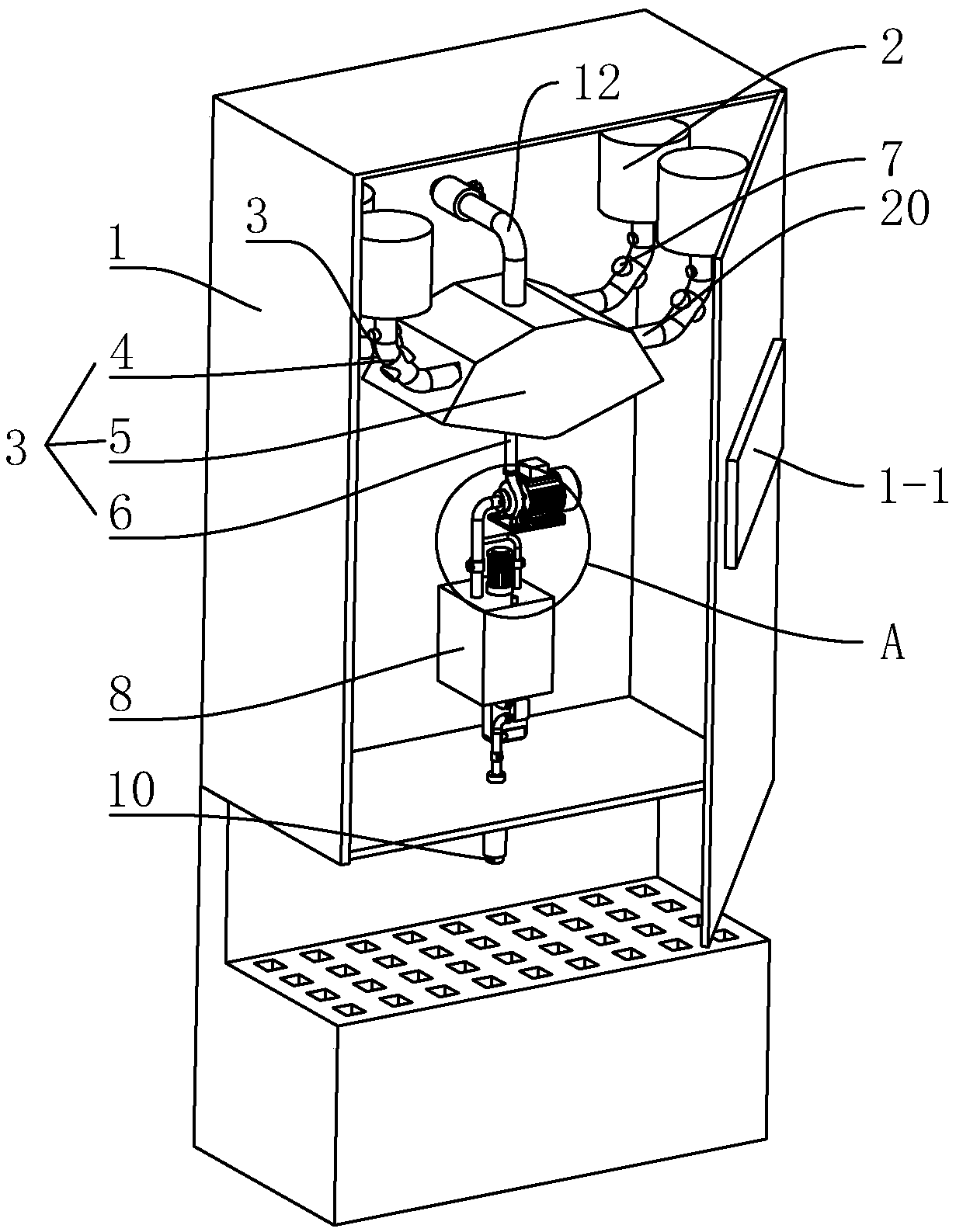

[0041] Embodiment 1, a kind of liquid drink automatic on-the-spot adjustment equipment, refer to figure 1 , including a cabinet 1, four storage boxes 2 are arranged on the upper part of the cabinet 1, the storage boxes 2 are equipped with a discharge assembly 3, the discharge assembly 3 is connected to the mixing box 8, and a discharge nozzle 10 is set at the lower end of the mixing box 8 For discharging, the cabinet 1 is also provided with a control panel 1-1 with a control system. The control system controls different amounts of materials to be unloaded from different storage boxes 2, and then the various materials are fully mixed through the stirring paddles in the stirring box 8 to realize a single production of beverages.

[0042] Continue to refer to figure 1 , the discharge assembly 3 includes a multi-port joint 5 fixed on the chassis 1, the upper and lower ends of the multi-port joint 5 are in the shape of a boss, and at the same time, two installation pipes 20 are re...

Embodiment 2

[0049] Embodiment 2, a modulation method:

[0050] S1. Input the quantity of each material required on the control system;

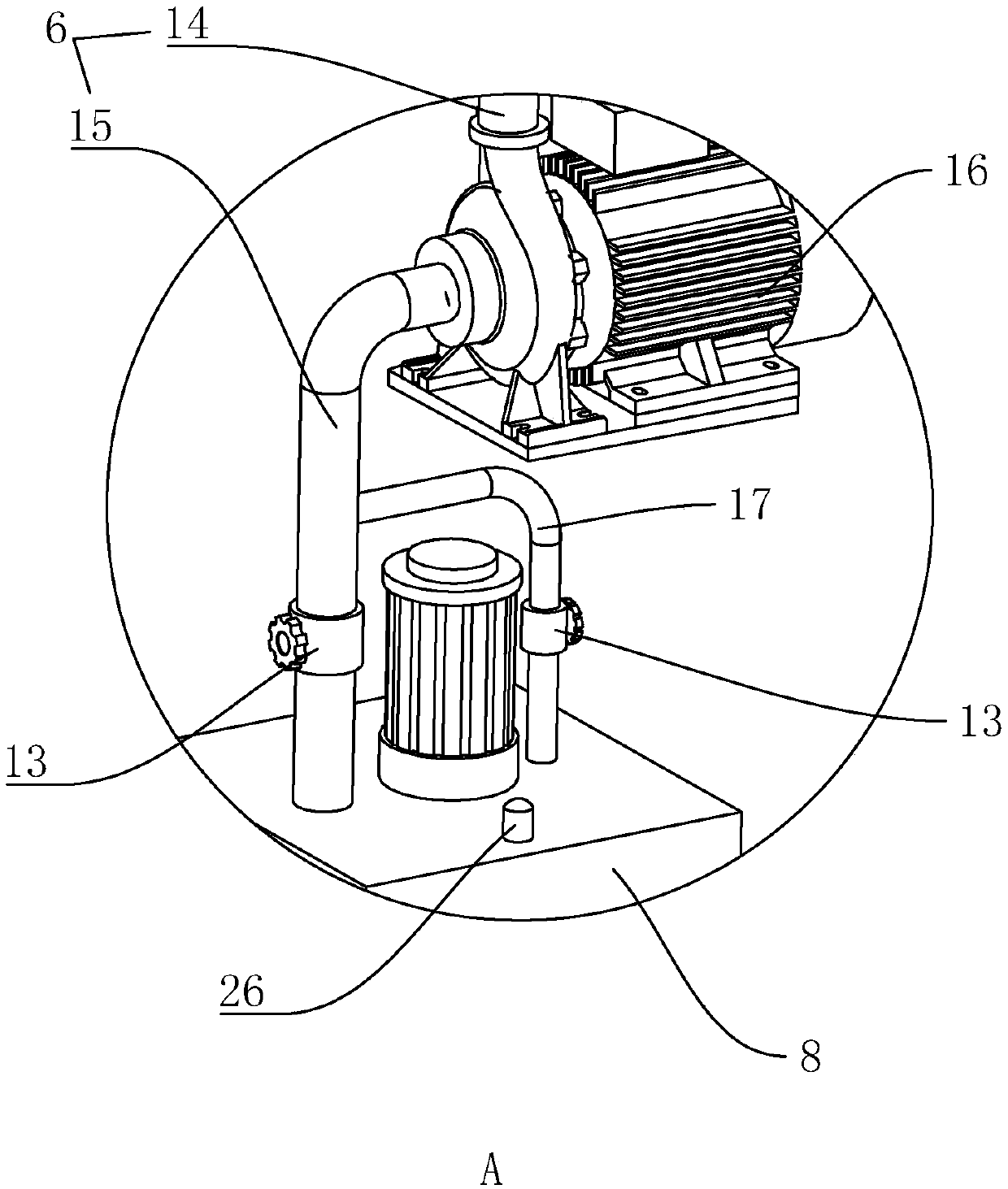

[0051] S2. The control system opens the opening and closing valve 13 on the feeding pipe 4, and the material is concentrated into the multi-port joint 5 and enters the collecting pipe 14. At the same time, when the actual value of the flow meter 7 on the feeding pipe 4 is the same as the preset value , storage box 2 stops feeding;

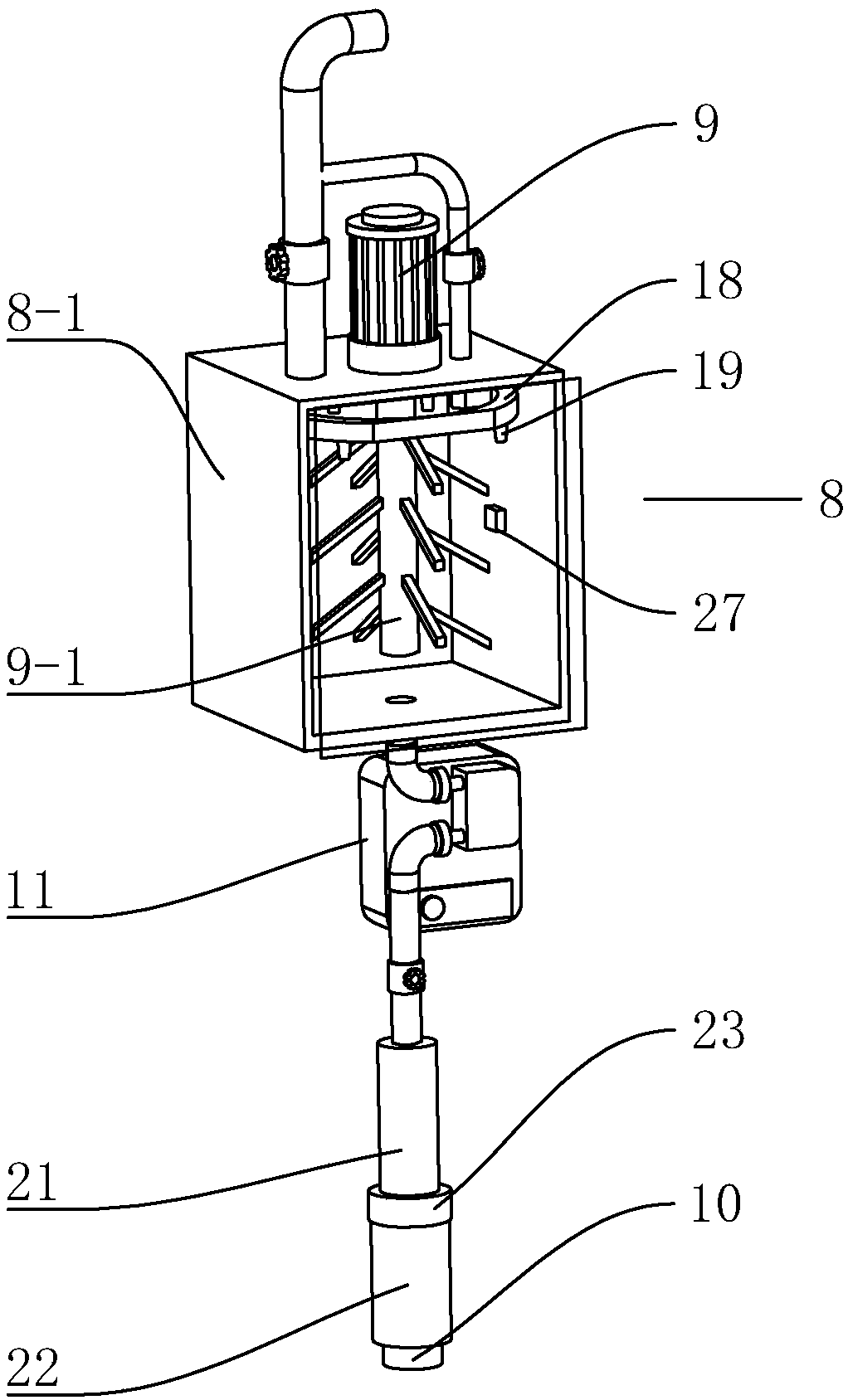

[0052] S3. After the material in the collecting pipe 14 is transported to the feeding pipe 15 by the centrifugal pump 16, the material enters the box 8-1, and the output motor 9 drives the stirring paddle 9-1 to stir the material;

[0053] S4. After the stirring is stopped for 20 seconds, the opening and closing valve 13 on the discharge nozzle 10 is opened, and the finished product is discharged into the drinking cup through the peristaltic pump 11;

[0054] S5. After the drink is made, the opening and closing valve 13 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com