An automobile door assembly jig

A technology for assembling jigs and car doors, which is applied to manufacturing tools, workpiece clamping devices, workbenches, etc., can solve the problems of poor versatility of door assembling jigs, high work intensity of workers, and low matching accuracy, and achieves reduction of assembly and debugging cycles. Reduce the debugging cycle and enhance the effect of matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

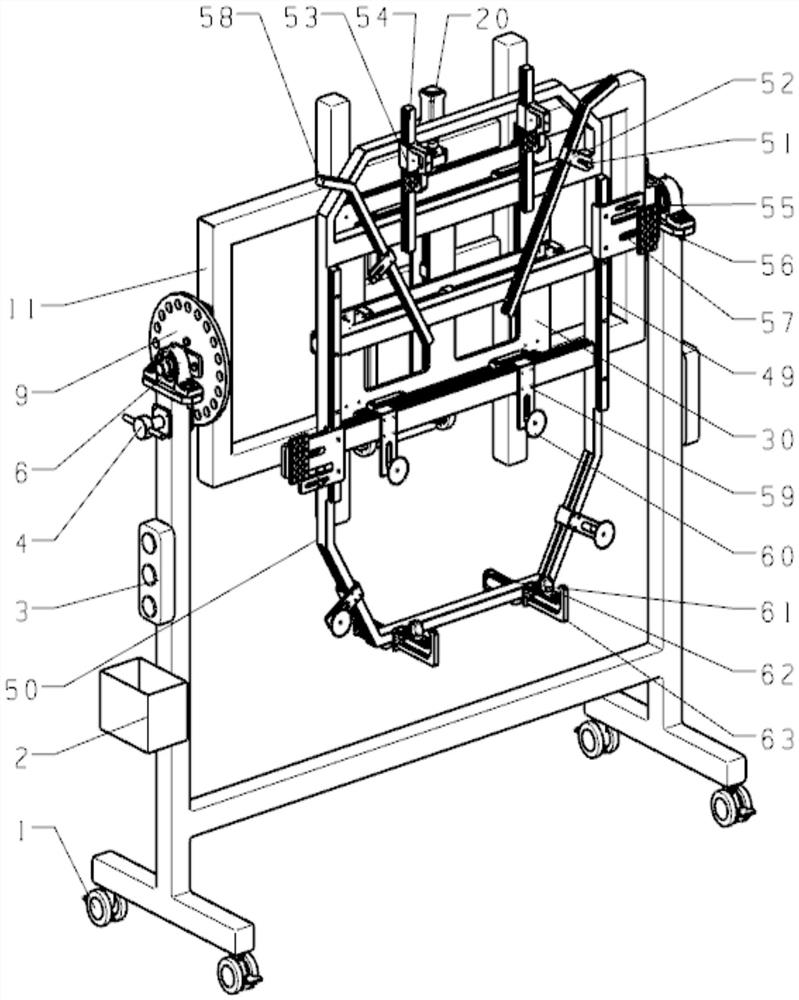

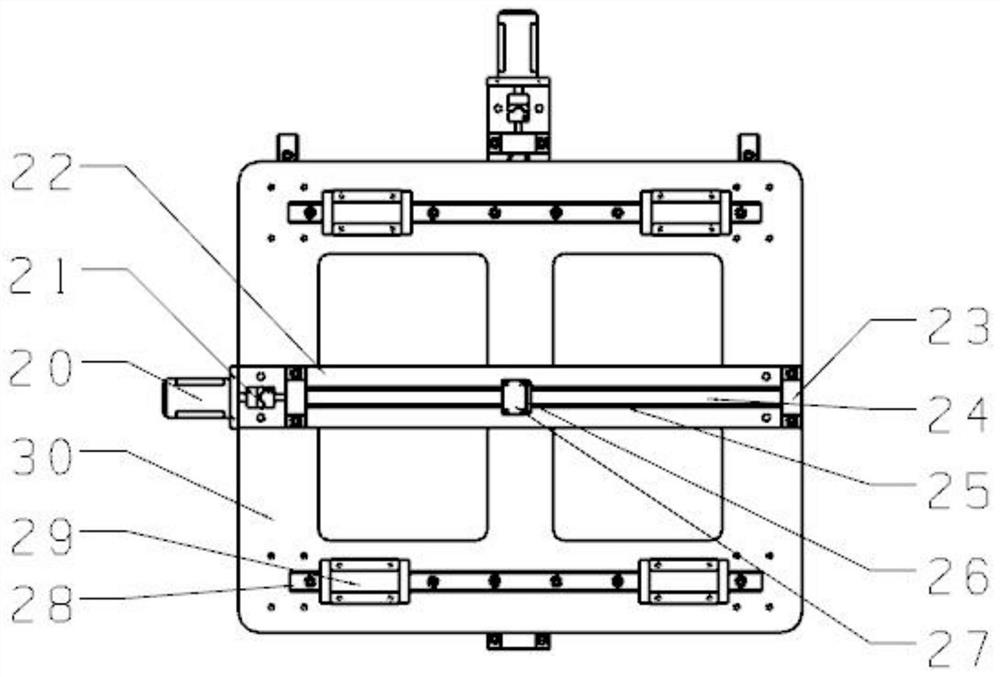

[0038] like figure 1Shown is a preferred embodiment of the automobile door assembly fixture of the present invention. The automobile door assembly fixture includes a fixture body module, a driving module, a positioning and clamping module, and a controller 3 . The three modules can be connected and fixed with bolts.

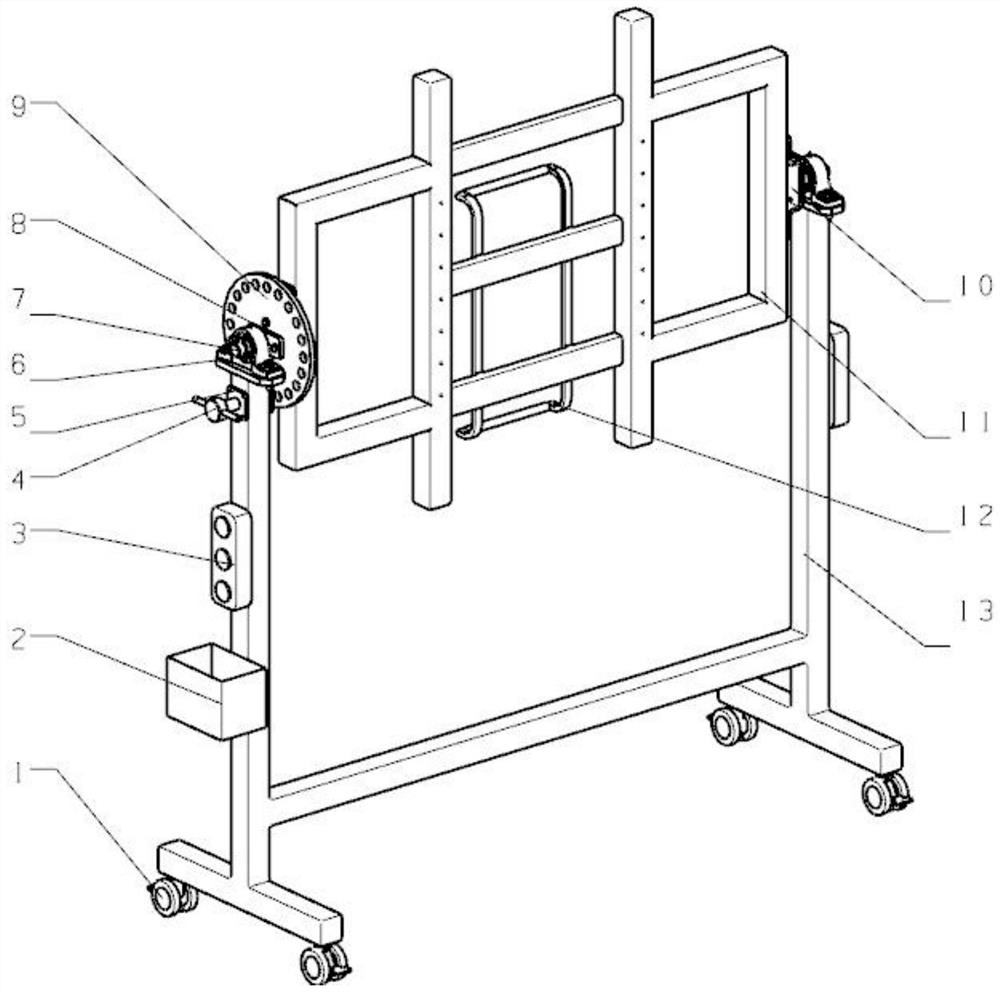

[0039] like figure 2 As shown, the fixture body module includes a frame module and a frame module, and the frame module includes a brake wheel assembly 1, a storage box 2, a controller 3, an indexing positioning pin 4, a guide block 5, and a bearing seat. 6. The rotating shaft 7 , the indexing plate connecting plate 8 , the indexing plate 9 and the frame 13 ; the frame module includes a connecting bracket 10 , a clamp frame 11 and a moving handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com