Paint collecting device for wood roll coating machine

A technology of collecting device and roller coating machine, which is applied to the device for coating liquid on the surface, coating, filtration and separation, etc. It can solve the problems of polluted paint and residual paint, and achieve less residual paint and good dust-proof effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, but not as the basis for limiting the present invention.

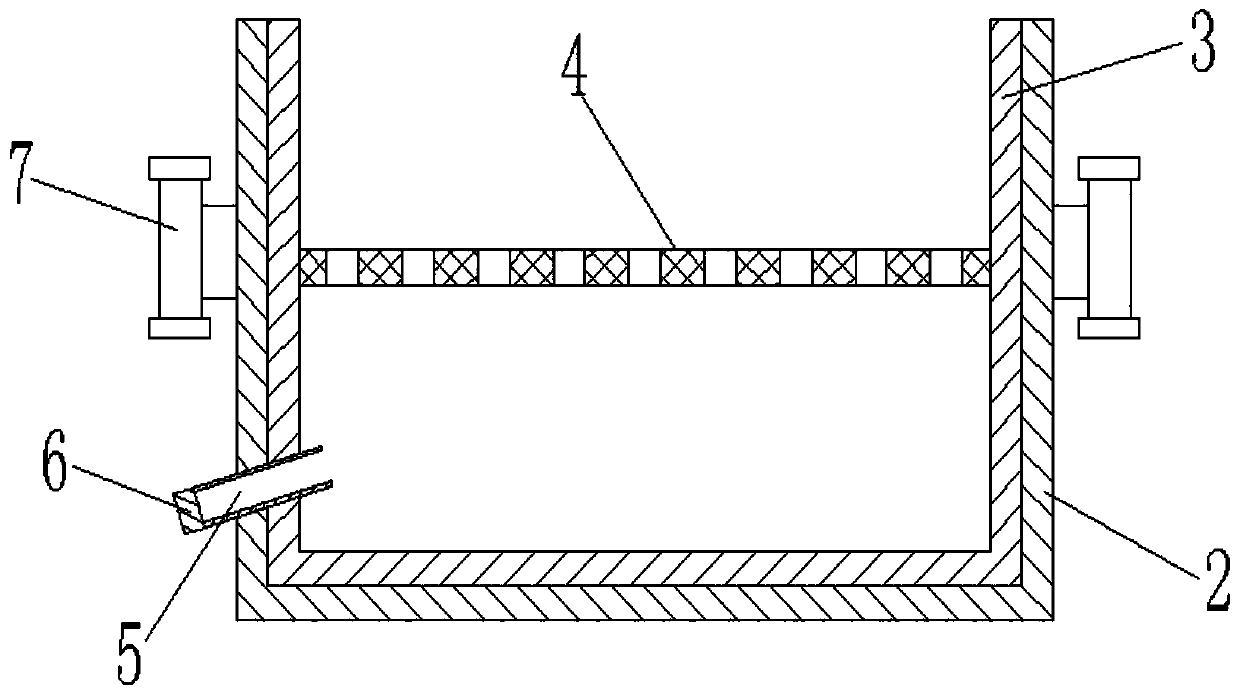

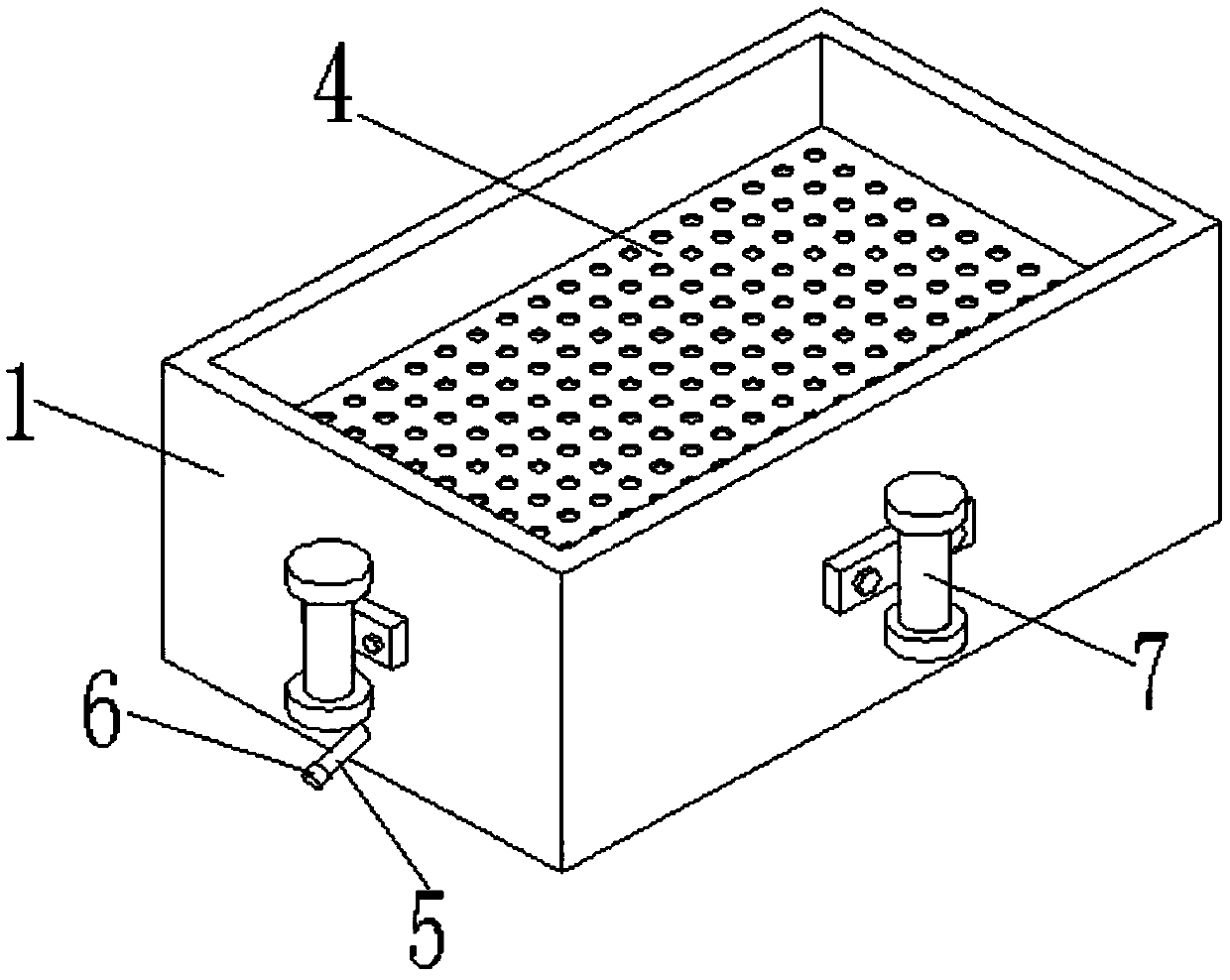

[0018] Example. Paint collecting devices for wood roller coaters, constructed as figure 1 As shown, a paint collection box 1 is included, and the paint collection box 1 is composed of a box body 2 and a blue crystal nano-liquid film layer 3 coated in the box body 2, and the blue crystal nano-liquid film layer 3 is made of a blue crystal nano-liquid film , the blue crystal nano liquid film is made of nano interface material, because the nano interface material has the characteristics of non-stick paint, so the paint will not stick on the blue crystal nano liquid film layer 3, so when the present invention pours out the paint, the present invention There is less residual paint left in the paint collection box 8. The paint collection box 1 is provided with a PP non-woven fabric layer 4, and the PP non-wov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap