Vibrating-type screening device of chemical raw materials

A technology for chemical raw materials and screening devices, which is applied in the fields of sieves, chemical instruments and methods, solid separation, etc. Improve operating efficiency and improve the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

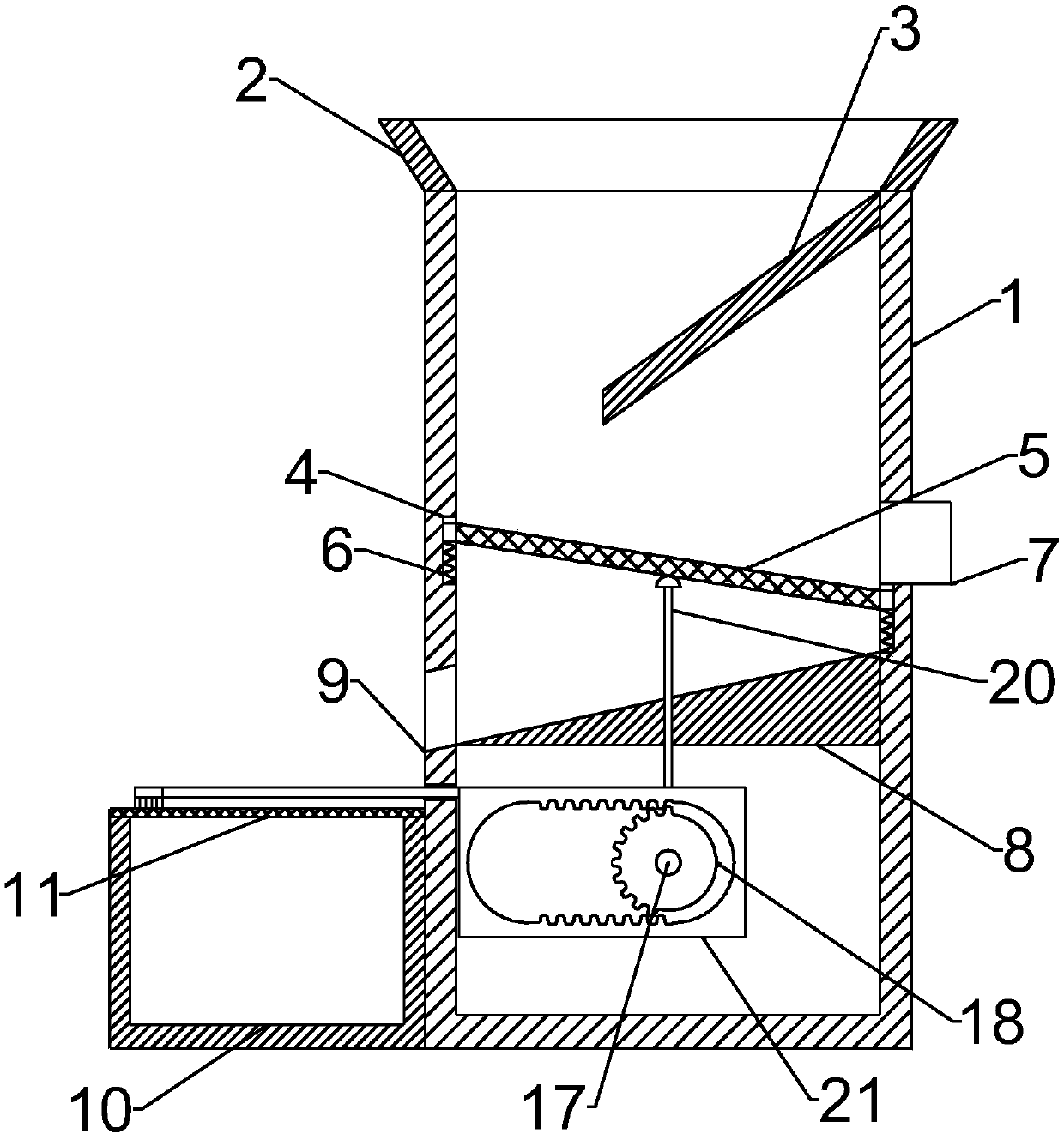

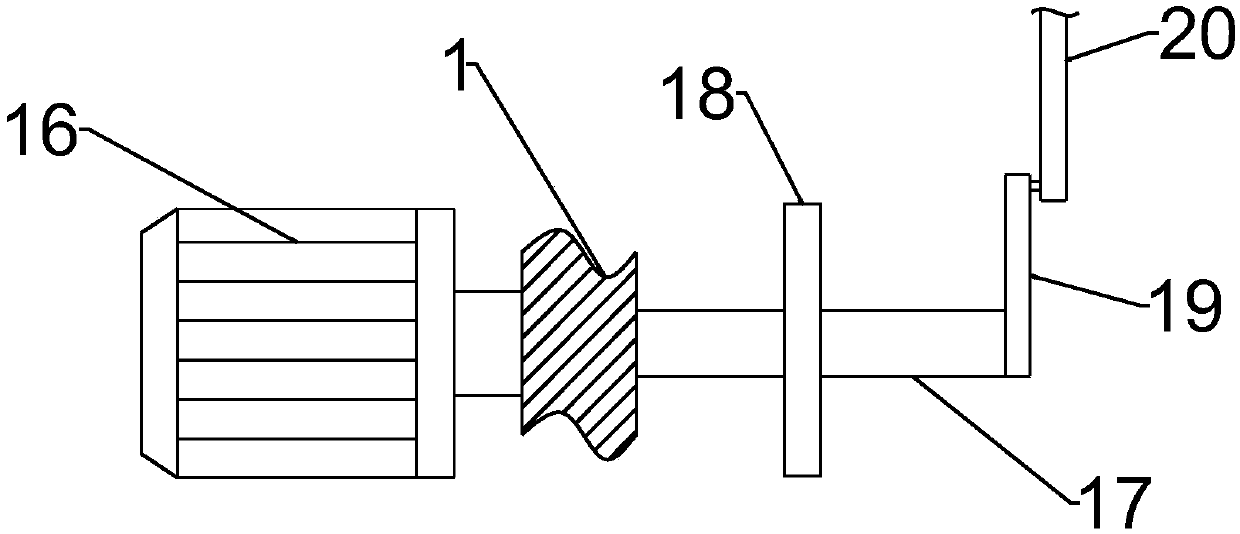

[0017] See Figure 1~2 In the embodiment of the present invention, a vibratory screening device for chemical raw materials includes a screening cavity 1, a first filter plate 5, a collecting chamber 10, a second filter plate 11, a motor 16, a rotating shaft 17 and an impact A rod 20, the two sides of the screening cavity 1 are embedded with installation grooves 4, a first filter plate 5 is connected between the installation grooves 4, and the lower end of the first filter plate 5 and the installation groove 4 There is a support spring 6 connected between the inner bottom, the left side of the screening cavity 1 is riveted with a collecting chamber 10, the upper end of the collecting chamber 10 is riveted with a second filter plate 11, the output end of the motor 16 is connected through The shaft is connected to the rotating shaft 17 for transmission, the end of the rotating shaft 17 is connected with an impact rod 20 through a connecting rod 19, and an incomplete gear 18 is wel...

Embodiment 2

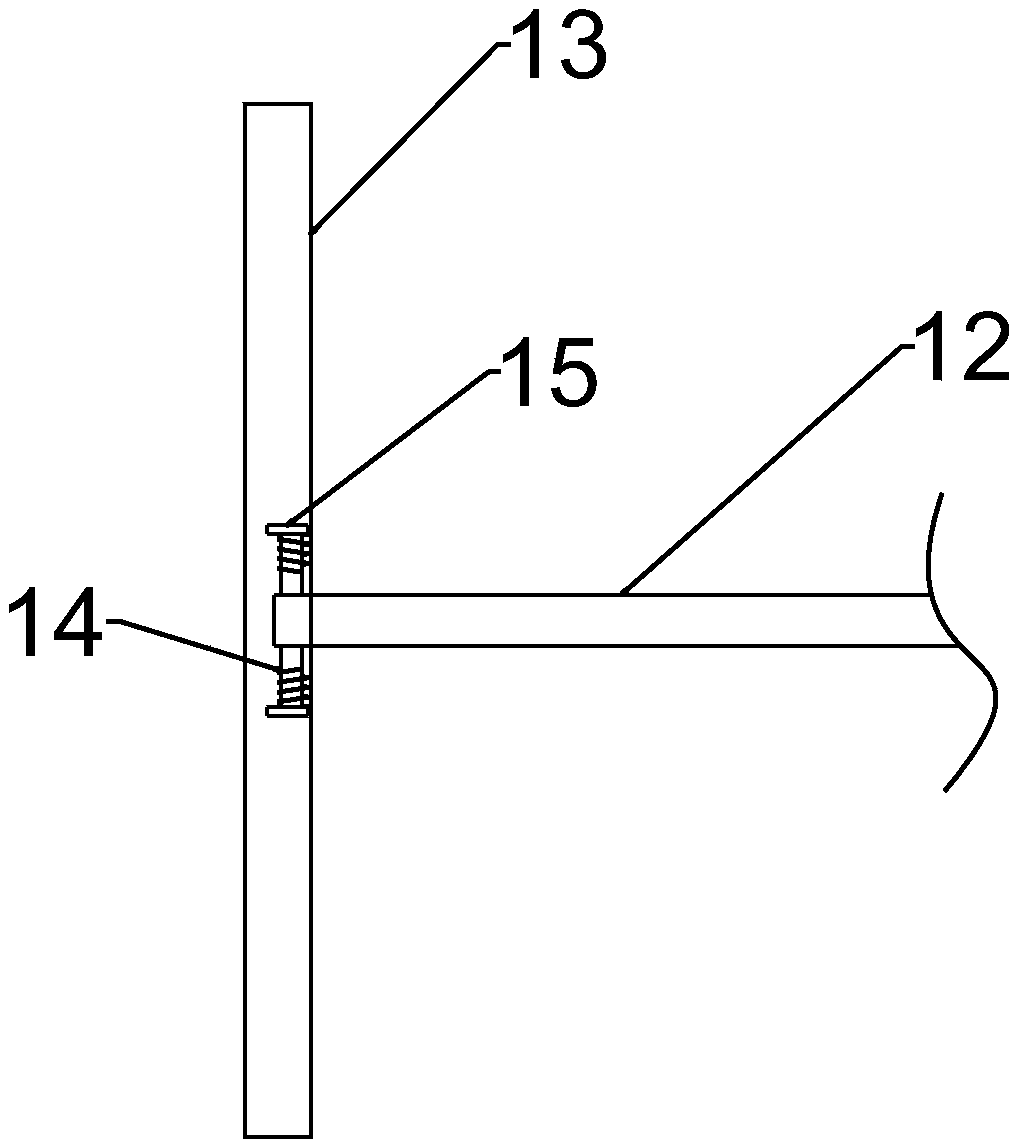

[0021] See image 3 In an embodiment of the present invention, a vibrating screening device for chemical raw materials, on the basis of embodiment 1, the sliding rod 12 is symmetrically welded with rotating pins 14 on both sides of the end, and the brush rod 13 has two upper and middle parts. A mounting plate 15 is provided for side-symmetric welding. The end of the rotating pin 14 is respectively connected to the mounting plate 15 on both sides in rotation, and a torsion spring is connected between the rotating pin 14 and the mounting plate 15.

[0022] The working principle of the present invention is: when in use, the motor 16 is started to drive the rotating shaft 17 to rotate, and the rotating shaft 17 drives the impact rod 20 to perform vertical reciprocating motion through the connecting rod 19, and the impact rod 20 continuously impacts the first filter screen during the vertical reciprocating motion. The lower end of the plate 5 makes the first filter plate 5 vibrate cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com