Shaping mold and method of thin-wall sheet metal parts

A forming method and technology of forming molds, applied in the field of sheet metal forming, can solve the problems that the size of the part cannot be guaranteed, cannot meet the use requirements, and the movement resistance of the guide rail increases, so as to save the percussion process, reduce labor intensity, Guaranteed effect of profile size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

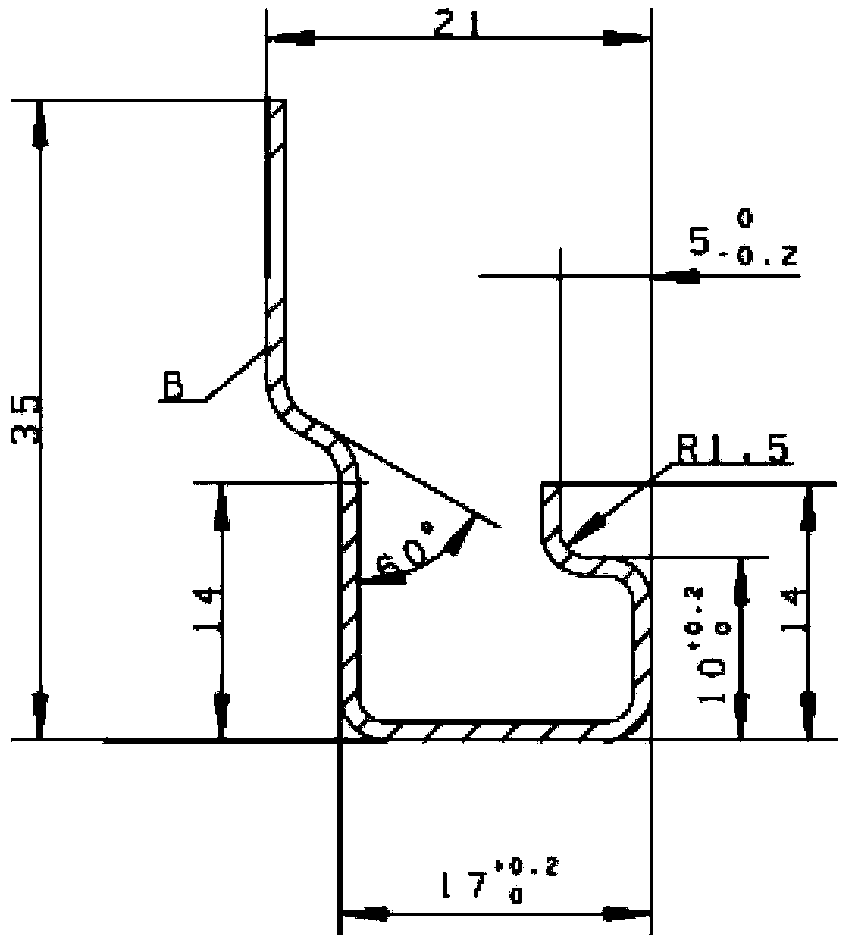

[0030] Such as figure 1 with Figure 7 Shown is the final size drawing of the parts processed by the present invention and the schematic diagram of the position of each bending section.

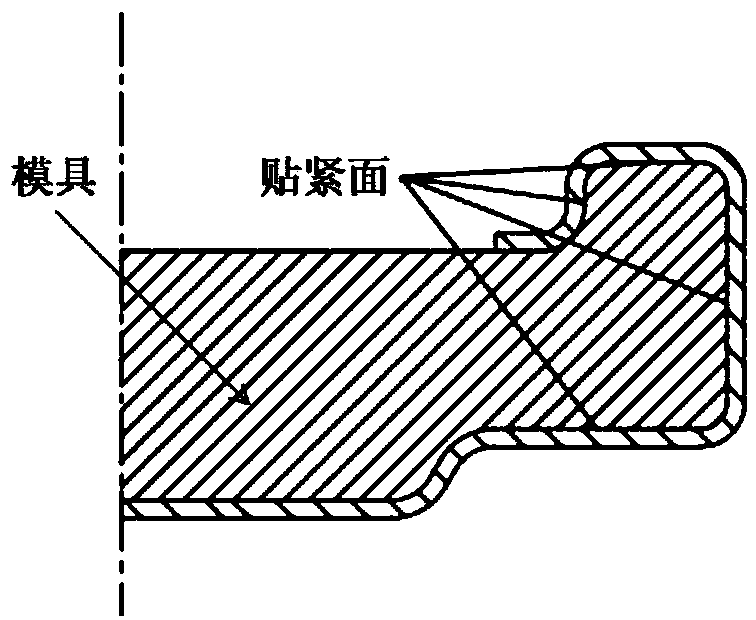

[0031] Such as figure 2 Shown is the schematic diagram of the existing processing method and mold.

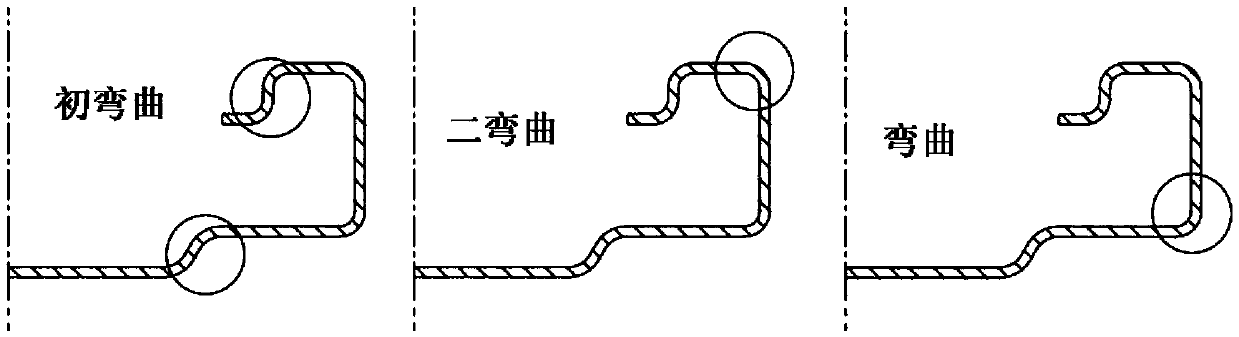

[0032] Such as image 3 As shown, it is a schematic diagram of the position corresponding to each bending in the three bendings of the present invention.

[0033] Such as Figure 4 As shown, the lower surface of the male mold of the first bending mold includes two sections of S-shaped curved surfaces, corresponding to the first S-shaped curved section 1 and the second S-shaped curved section 4, respectively, and the two sections of S-shaped curved surfaces and the outer sides are respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com