A method for manufacturing fully adaptive support tooling for soft mold auxiliary support

A technology of auxiliary support and manufacturing method, which is applied in the field of fully adaptable support tooling manufacturing, can solve problems that affect product manufacturing accuracy, product molding quality, fiber folds or buckling, and poor support structure strength, so as to reduce production costs and manufacturing cycles, Avoid wrinkling or buckling, stable state effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

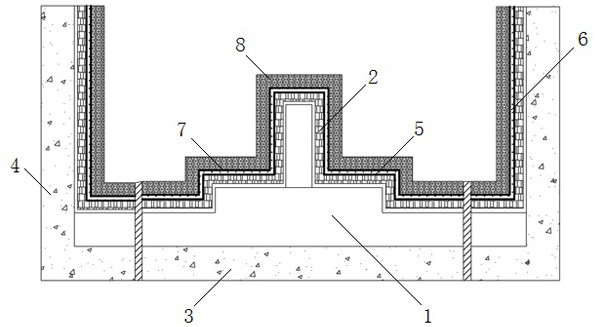

[0029] The technical solutions of the present invention will be clearly and completely described below with reference to the embodiments and the accompanying drawings. Obviously, the described embodiments are only the preferred embodiments of the present invention, not all the embodiments, nor are they intended to be used for the present invention. Any other form of limitation, any person skilled in the art may use the disclosed technical content to make changes or modifications and equivalent changes. However, any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention without departing from the content of the technical solutions of the present invention still belong to the protection scope of the technical solutions of the present invention.

[0030] This embodiment is a manufacturing method of a fully adaptable support tool for auxiliary support of a soft mold. The soft film includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com