Adjustable pipeline mounting, welding, assembling and moving emplacement device

A welding assembly and pipeline installation technology, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of incapable pipeline assembly, single function, and inability to improve the efficiency of pipeline processing and installation, and achieve compact structure and improved work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

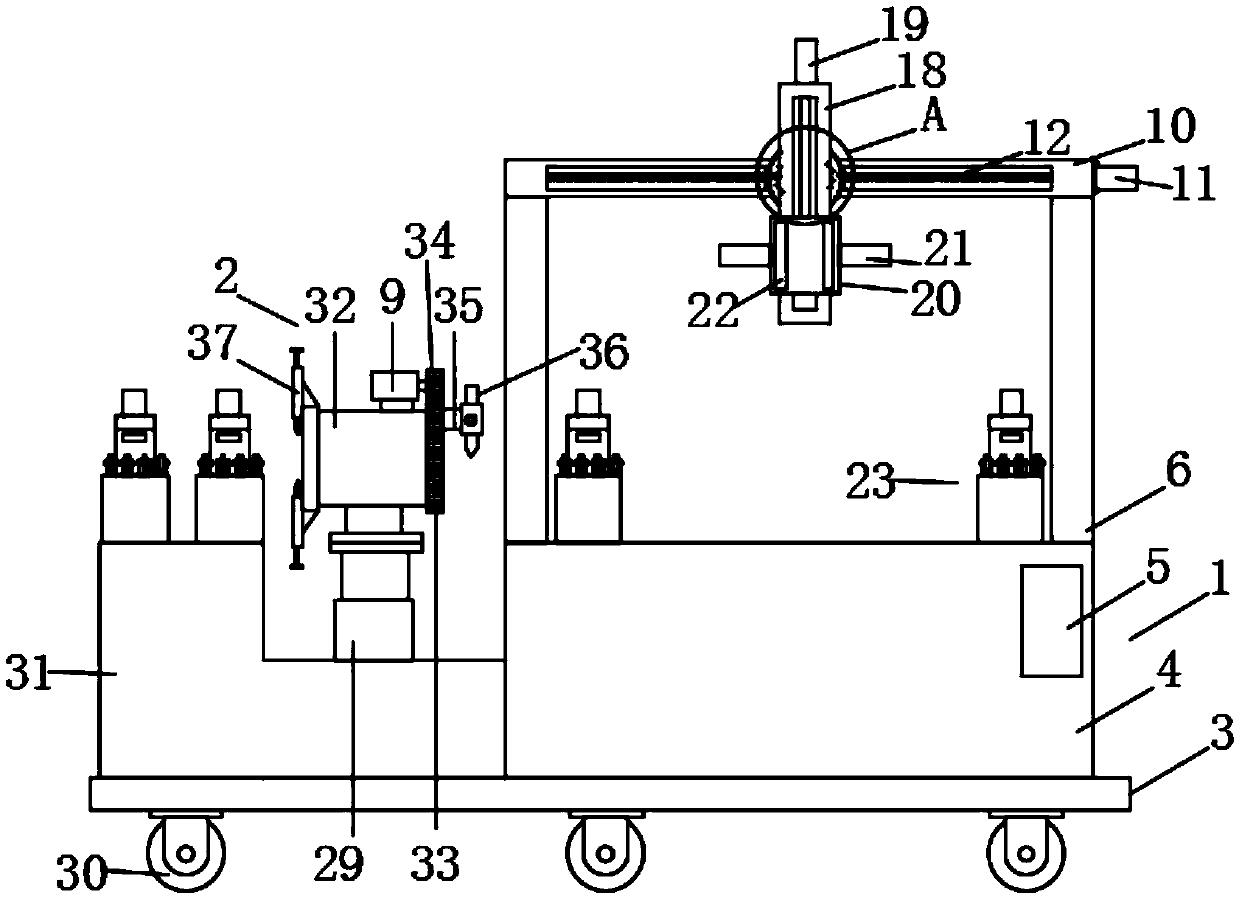

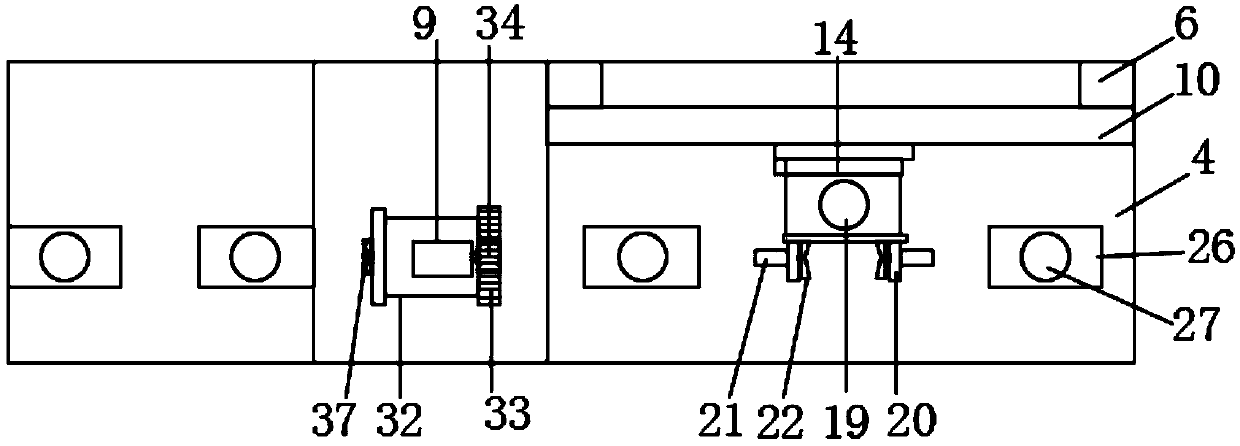

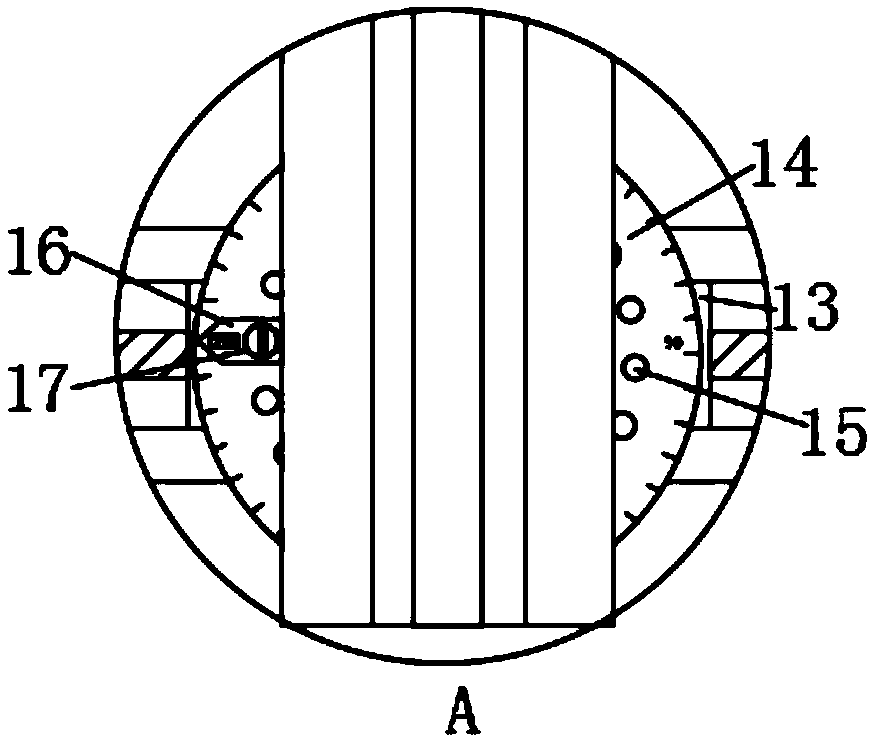

[0023] Example: such as Figure 1-6 As shown, a device for installing, welding, assembling, and moving an adjustable pipeline in the present invention includes an installation mechanism 1 and a welding mechanism 2. Knife 7, beam 10, moving motor 11, moving screw rod 12, moving slider 13, angle plate 14, limit hole 15, angle pin 16, limit pin 17, lifting chute 18, lifting cylinder 19, fixed sliding table 20. Clamping cylinder 21, clamping fixture 22 and limit fixture 23, one end of the top of the mobile base 3 is fixedly connected to the workbench 4, and both ends of the top of the workbench 4 are fixedly connected to the support column 6, A crossbeam 10 is fixedly connected between the tops of the two supporting columns 6, and one end of the crossbeam 10 is fixedly connected with a moving motor 11, and the inner rotation of the crossbeam 10 is connected with a moving screw 12, and the output of the moving motor end is fixedly connected with one end of the moving screw rod, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com