A gas cylinder heat protection structure and gas cylinder for the influence of large plume of attitude control engine

A heat protection structure and engine technology, applied in fluid treatment, mechanical equipment, gas treatment applications, etc., can solve problems affecting safety and boosting capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

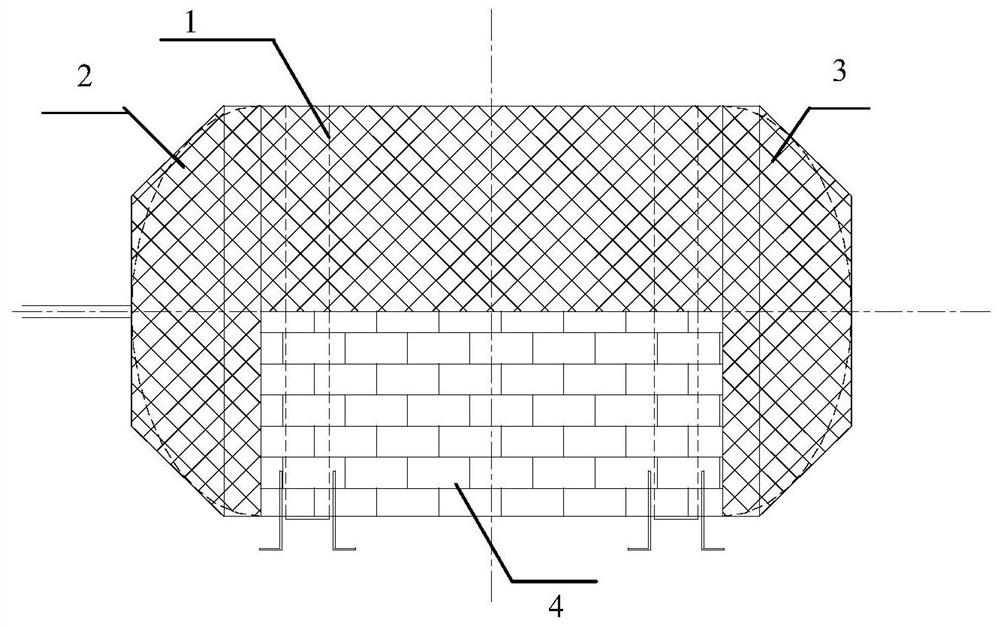

[0040] Such as figure 1 Shown is a schematic diagram of the thermal protection structure of the gas cylinder of the present invention. It can be seen from the figure that the thermal protection structure of the gas cylinder of the present invention includes a flexible heat-proof layer and a multi-layer heat insulation component, wherein the multi-layer heat insulation component is coated on the surface of the cylindrical section of the gas cylinder. A flexible heat shield covers the surfaces of the hemispheres at both ends of the gas cylinder and the surface of the multilayer insulation assembly in the cylindrical section of the gas cylinder. Such as figure 1 Shown are a cylindrical section flexible heat shield 1 , an upper hemispherical flexible heat shield 2 , a lower hemisphere flexible heat shield 3 and a multilayer heat insulation assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com