Waste heat recovery device and waste heat recovery method based on outlet smoke temperature control

A technology of outlet smoke temperature and waste heat recovery, applied in steam generation method using heat carrier, lighting and heating equipment, components of steam boiler, etc., to achieve enhanced ability of variable load and disturbance, simplified control process, and flexible control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

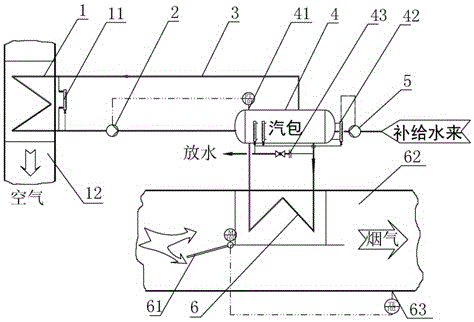

[0035] The schematic diagram of the waste heat recovery device based on outlet smoke temperature control of the present invention is as follows figure 1 As shown, it mainly consists of a combustion air air side finned tube heat exchanger 1, a magnetic flap liquid level sensor 11 with an output signal, an air side flue 12, a condensed water circulation pump 2, a saturated steam output pipe 3, and a steam drum 4 , steam drum pressure sensor 41, magnetic flap liquid level gauge 42, drain valve 43, make-up water pump 5, flue gas side fin heat exchanger 6, flue gas baffle 61, flue gas side flue 62, tail flue gas Air temperature sensor 63 constitutes.

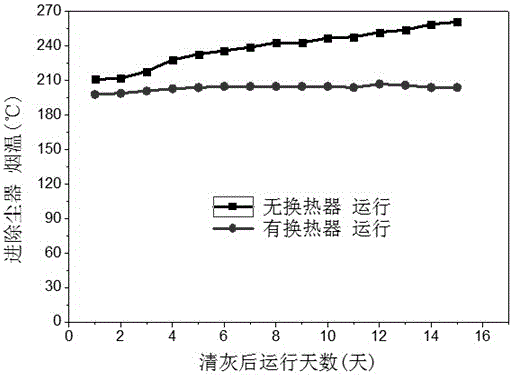

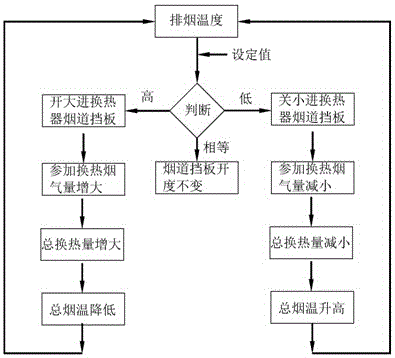

[0036] In order to ensure the full recovery of flue gas waste heat and the requirement that the flue gas outlet temperature is stable within a safe range, the present invention adds a heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com