Sizing device for conveying and loading cigarettes conveniently

A setting device and cigarette technology, applied in packaging and other directions, can solve the problems of heavy workload, easy deformation and depression of cigarettes, and achieve the effects of avoiding position shift, improving efficiency and quality, and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

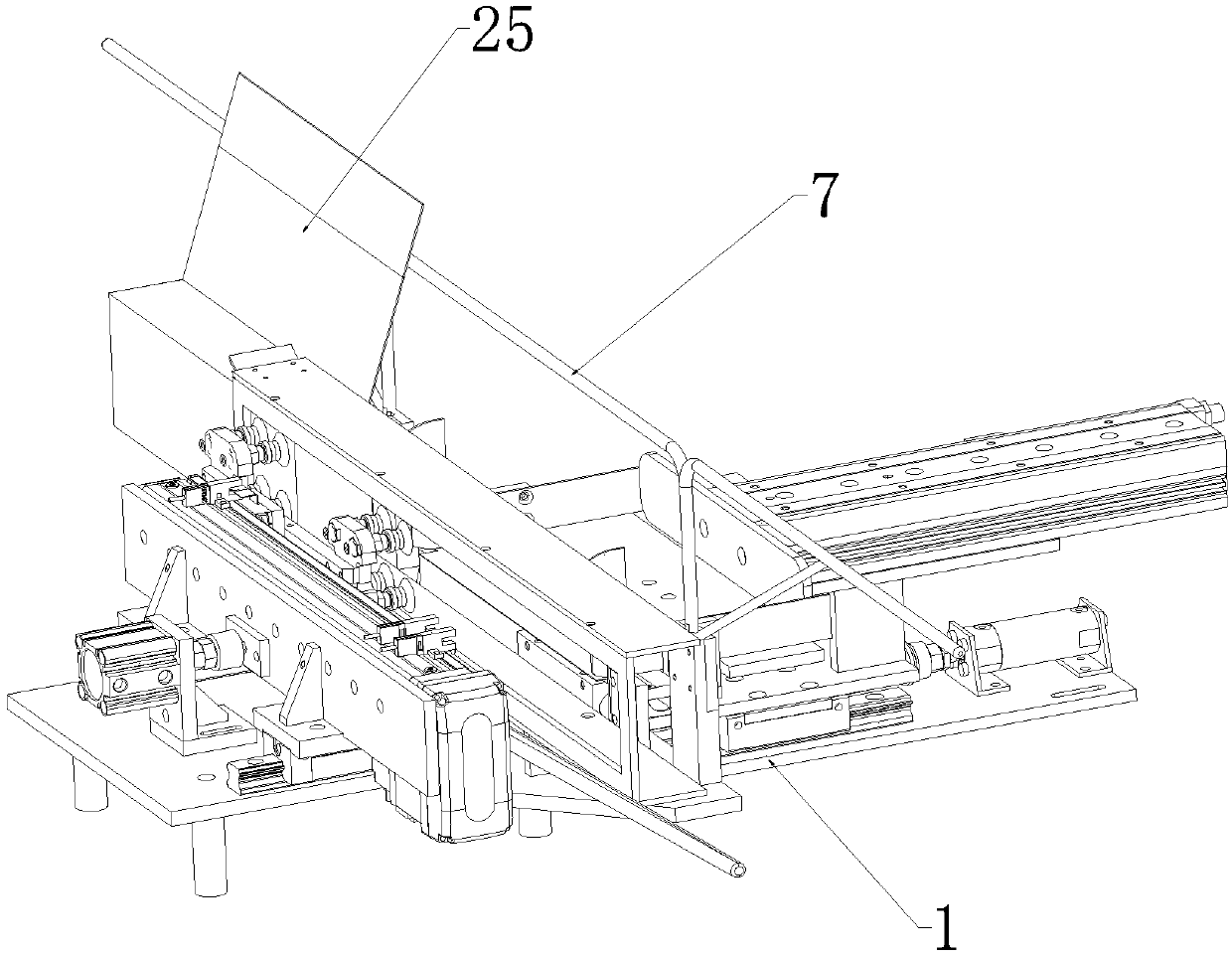

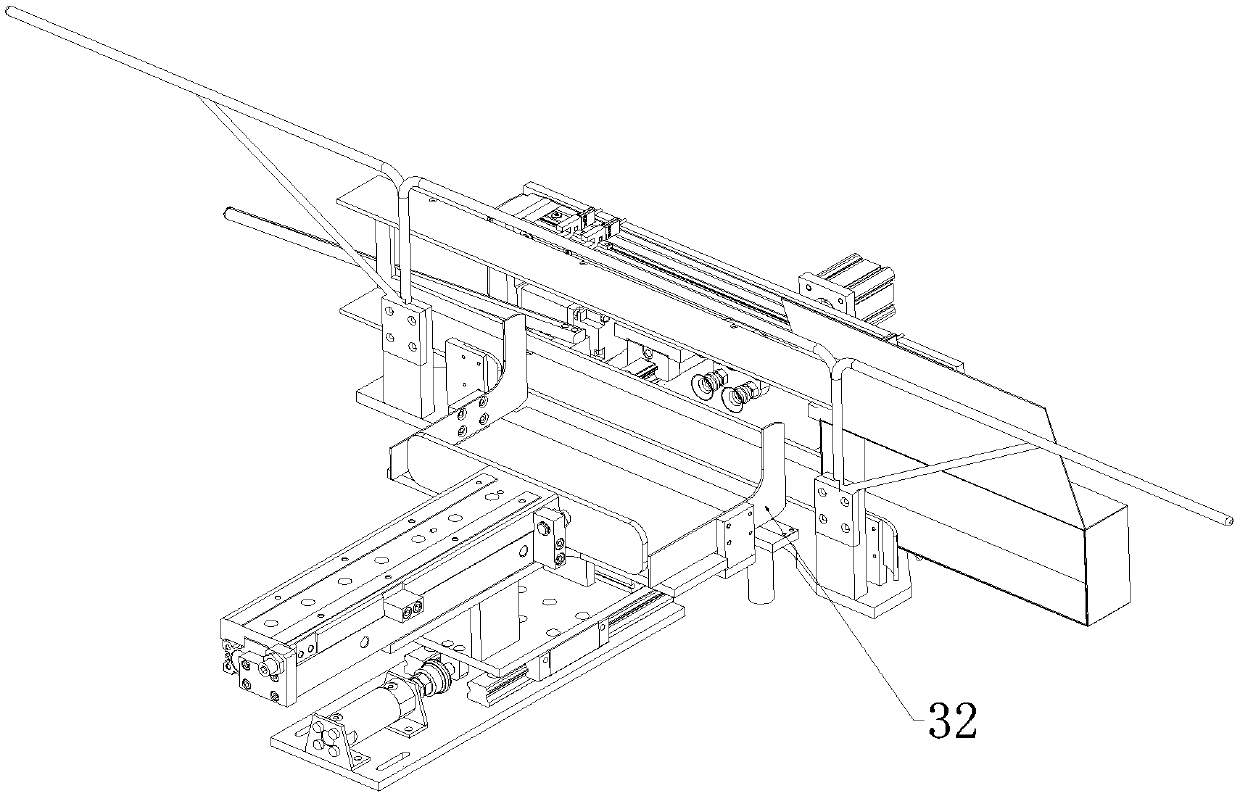

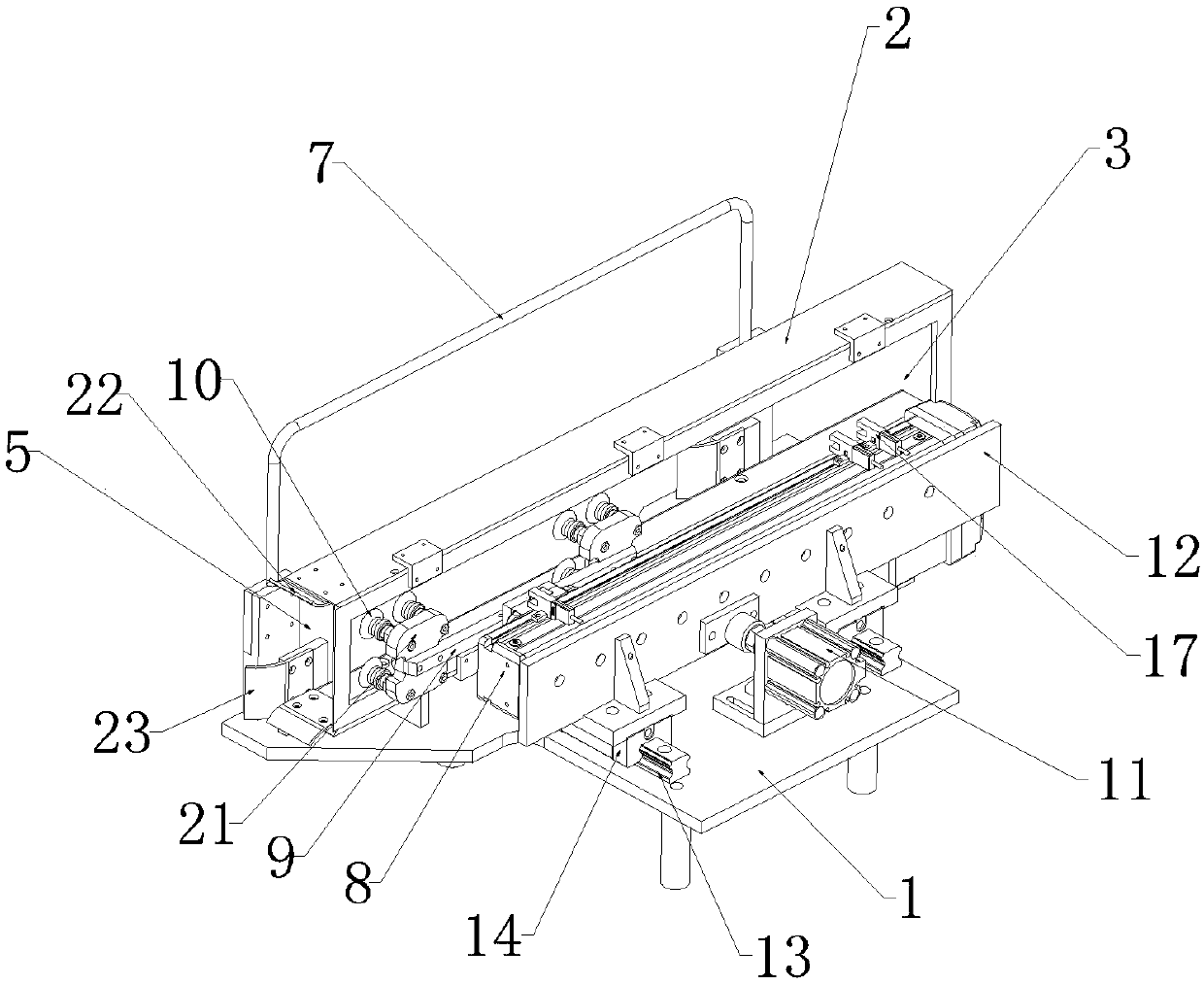

[0058] Such as Figure 1 to Figure 10 As shown, the shaping device for convenient delivery and loading of cigarettes includes a base 1;

[0059] A sizing frame 2, a first driving device 27 positioned in front of the sizing frame 2 and a second driving device 11 positioned at the rear of the sizing frame 2 are installed on the base 1;

[0060] The front end of the sizing frame 2 is concaved with a sizing groove 4, the rear end of the sizing frame 2 is provided with an opening 3 communicating with the sizing groove 4, and the left and right ends of the sizing frame 2 are respectively provided with a feed port 5 and a discharge port 6. Both the feed port 5 and the discharge port 6 are connected with the shaping frame 2;

[0061] The output end of the first driving device 27 is connected with a stretching mounting frame 28, and a supporting plate 31 and a third driving device 29 are installed on the stretching mounting frame 28. The third driving device 29 has two outputs that ca...

Embodiment 2

[0066] This embodiment makes the following further limitations on the basis of embodiment 1: the base 1 is equipped with a first guide rail 33 arranged in the front and rear directions;

[0067] The first guide slider 34 that can cooperate with the first guide rail 33 is installed on the described expansion mounting bracket 28;

[0068] The base 1 is provided with a second guide rail 14 arranged forward and backward, and a second guide rail 13 which can cooperate with the second guide rail 14 is installed on the suction cup mounting frame 12 .

[0069] In this embodiment, two first guide sliders 34 may be provided on the spreader mounting frame 28 , and the two first guide sliders 34 are slidingly matched with the two first guide rails 33 respectively. The suction cup mounting frame 12 is provided with two second guide rails 13 , and the two second guide rails 13 are slidingly matched with the two second guide rails 14 respectively.

Embodiment 3

[0071] This embodiment makes the following further limitations on the basis of embodiment 1: two supporting bases 15 are installed on the base 1;

[0072] The supporting section 7 is installed on two supporting bases 15 through the connecting section 16 .

[0073] In this embodiment, the left and right ends of the supporting section 7 are connected with connecting sections 16 , and the bottom ends of the two connecting sections 16 are respectively connected with the two supporting seats 15 . The support seat 15 is positioned at the front of the shaping frame 2, to prevent the support seat 15 from affecting the hard outer packaging from entering the feed port 5, a second guide plate 23 can be installed at the rear end of the support seat 15 near the feed port 5, The second guide plate 23 is provided with an arc segment extending outward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com