Discharge port connecting device for rotary equipment

A technology of connecting device and discharge port is applied in the field of connecting device of discharge port, which can solve the problems of easy retention, foreign matter mixing, deterioration, etc., and achieve the effects of avoiding material leakage, avoiding pollution, and having a simple and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

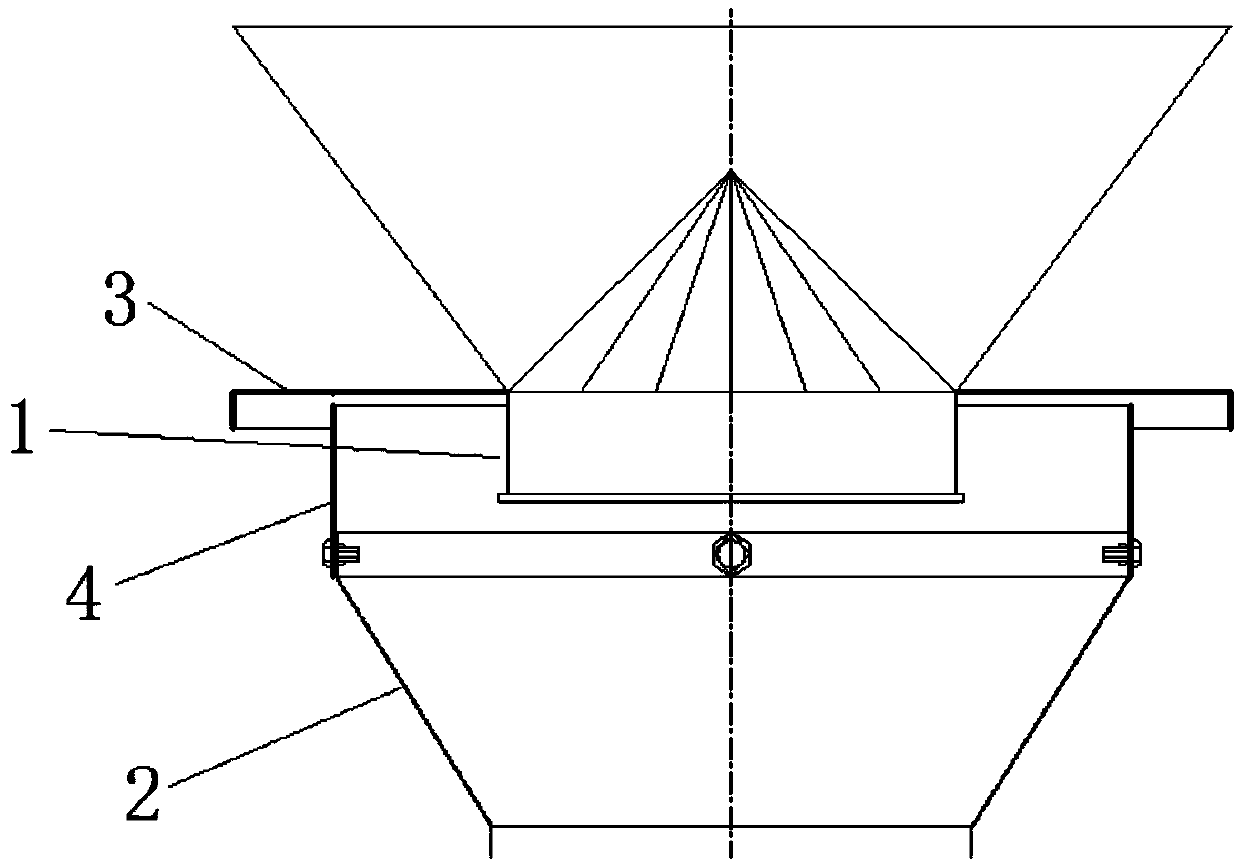

[0042] Such as figure 1 As shown, the present invention provides a connection device for the discharge port of the rotary device. The rotary device includes a discharge port 1 and a hopper 2 located below the discharge port 1. The discharge port 1 is the top feed pipe of the rotary device. The discharge port 1 at the bottom of the rotary equipment or the discharge port 1 at the bottom of the rotary equipment, the receiving hopper 2 is used to accept the materials transported through the discharge port 1; the connection device includes:

[0043] Cover plate 3, the cover plate 3 is ring-shaped, sleeved on the outer wall of the discharge port 1;

[0044] The baffle 4, the baffle 4 is cylindrical, connected to the top of the hopper 2 and surrounds the discharge port 1, and the outer periphery of the cover 3 is located radially outward of the baffle 4.

[0045] In this embodiment, the cover plate 3 is fixedly connected to the discharge port 1 by welding.

[0046] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com