Floor drain for three-stage sewage separation

A floor drain and sewage technology, which is applied in petrochemical and marine engineering fields, to achieve the effect of convenient maintenance, simple structure and anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

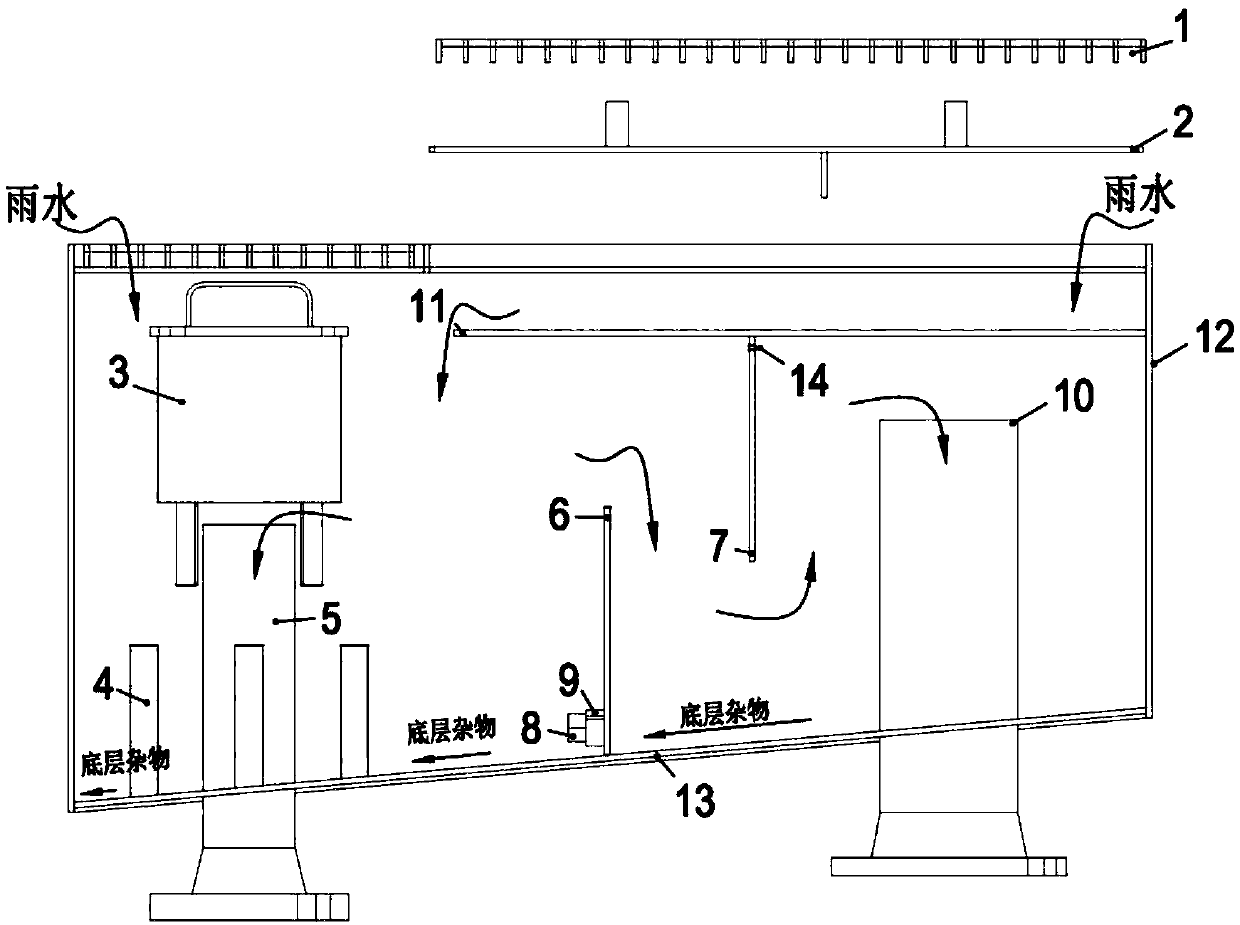

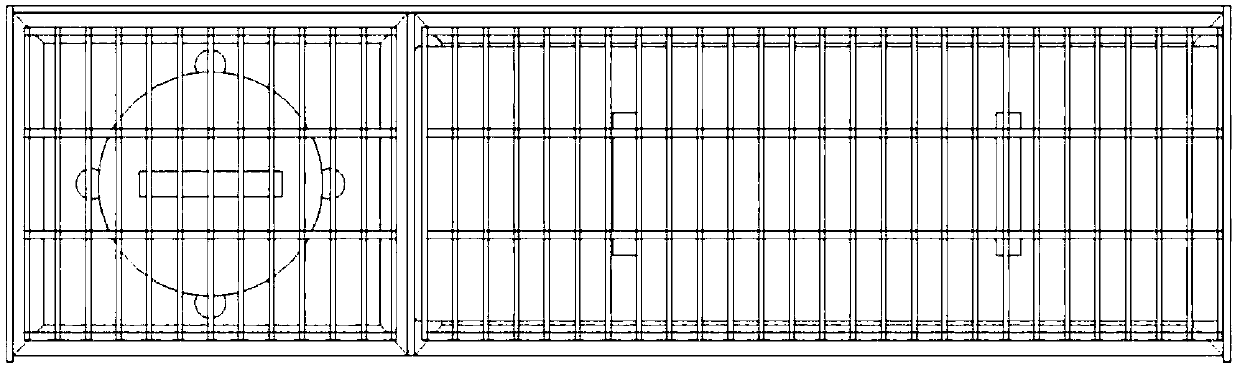

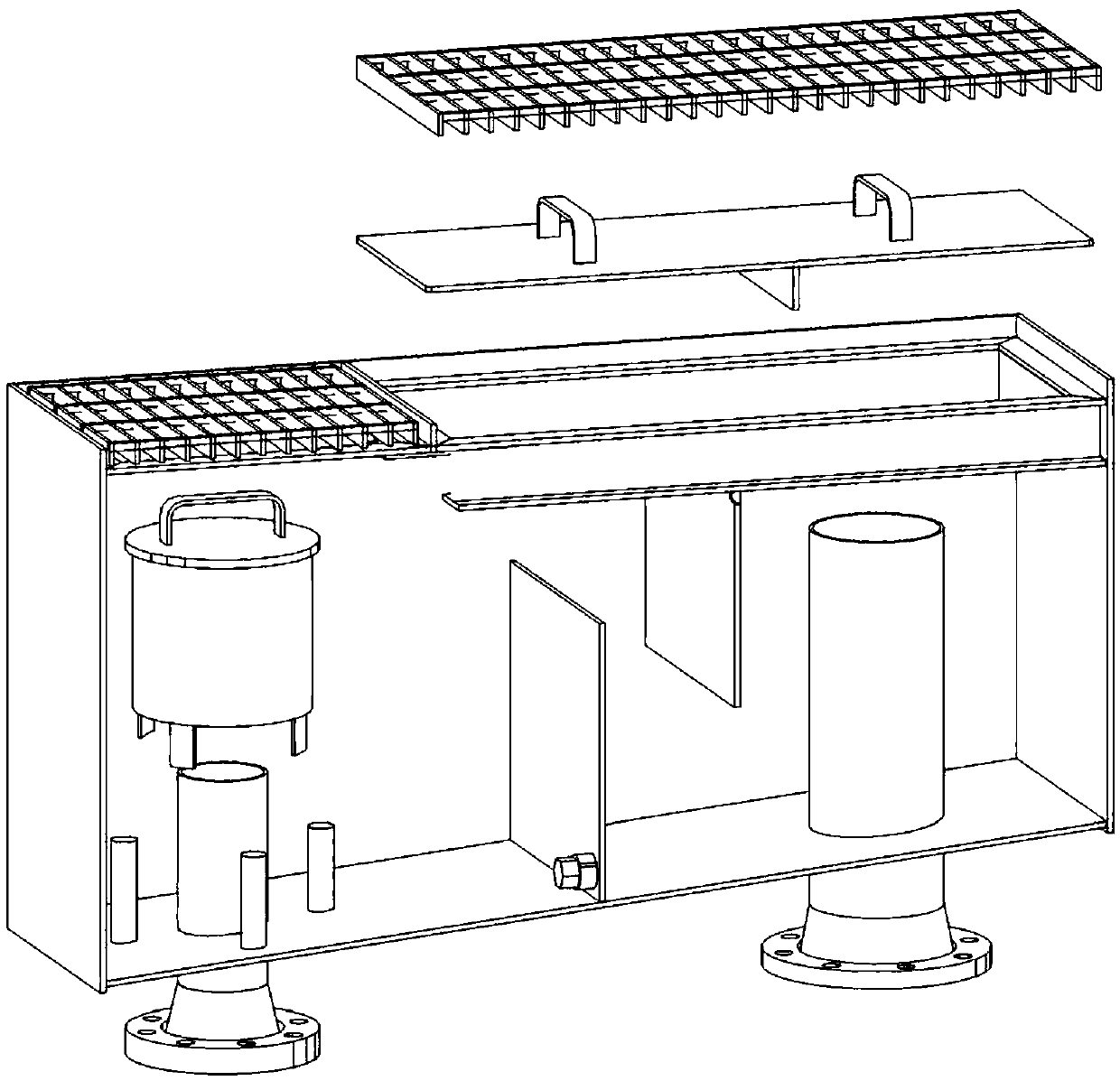

[0019] Such as Figure 1-Figure 3 As shown, the present invention comprises: box body, the grille 1 that is arranged on the box body and movable cover plate 2, wherein, the inside of box body is equipped with cover bucket 3, and the bottom of cover bucket 3 is oppositely installed with main drainage pipe 5 and Several partitions (this implementation is: the first partition 6 and the second partition 7); the first partition 6 and the second partition 7 are provided with threaded plugs 8 and process holes 14; and A movable cover plate support 11 is horizontally installed on the second partition 7; a spare drain pipe 10 is arranged inside the casing, and several round steels 4 (four in this embodiment) are installed on the periphery of the above-mentioned main drain pipe 5; The steel 4 is installed on the bottom plate 13 of the box body by welding; and the bottom plate 13 is arranged obliquely.

[0020] The above-mentioned main drain pipe 5 passes through the bottom plate 13 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com