Main frame for modular combined anti-seismic support and hanger anti-seismic performance detection equipment

A technology for seismic performance and testing equipment, which is used in the testing of mechanical equipment, machine/support, machine/structural components, etc. Achieve the effect of modular production and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

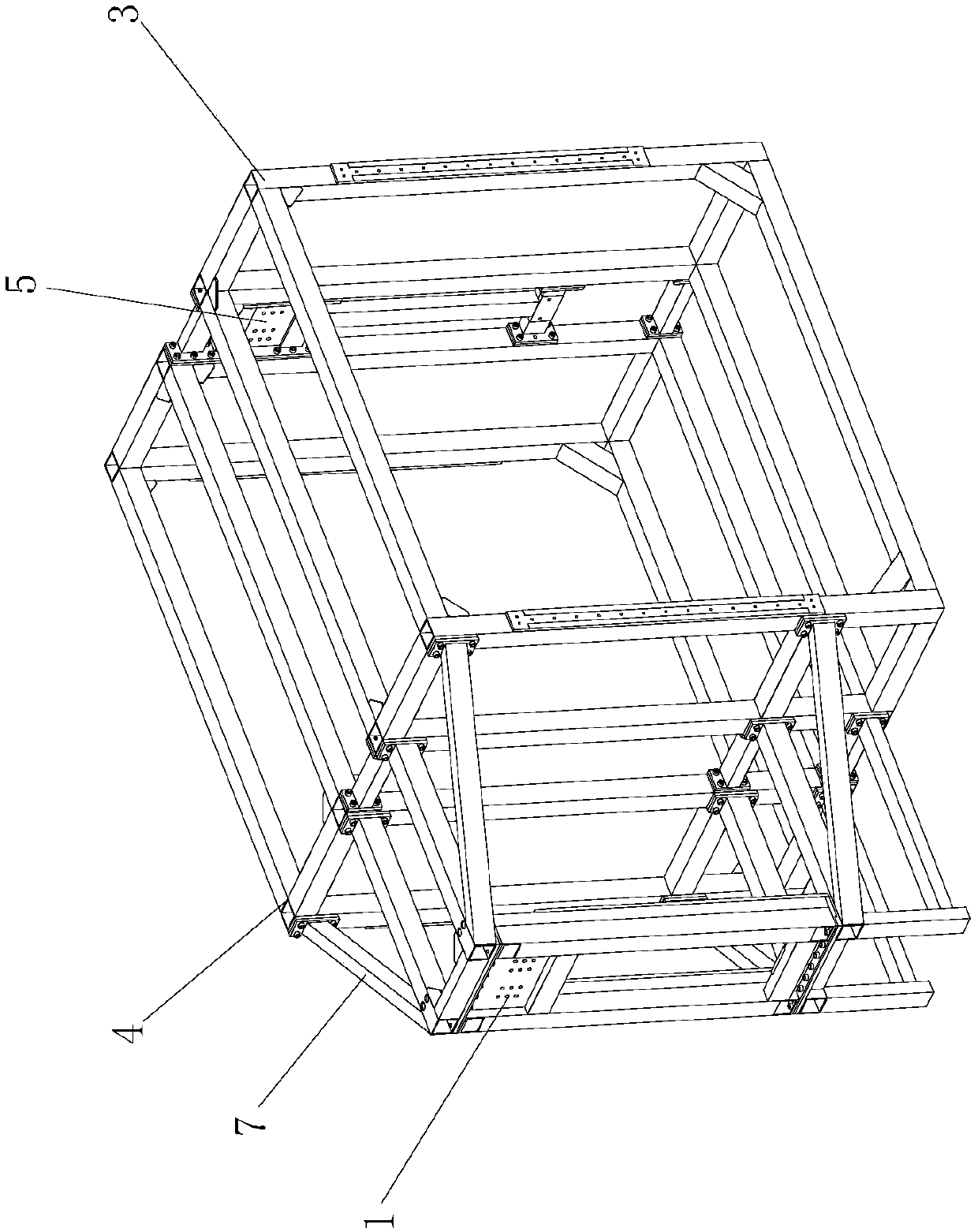

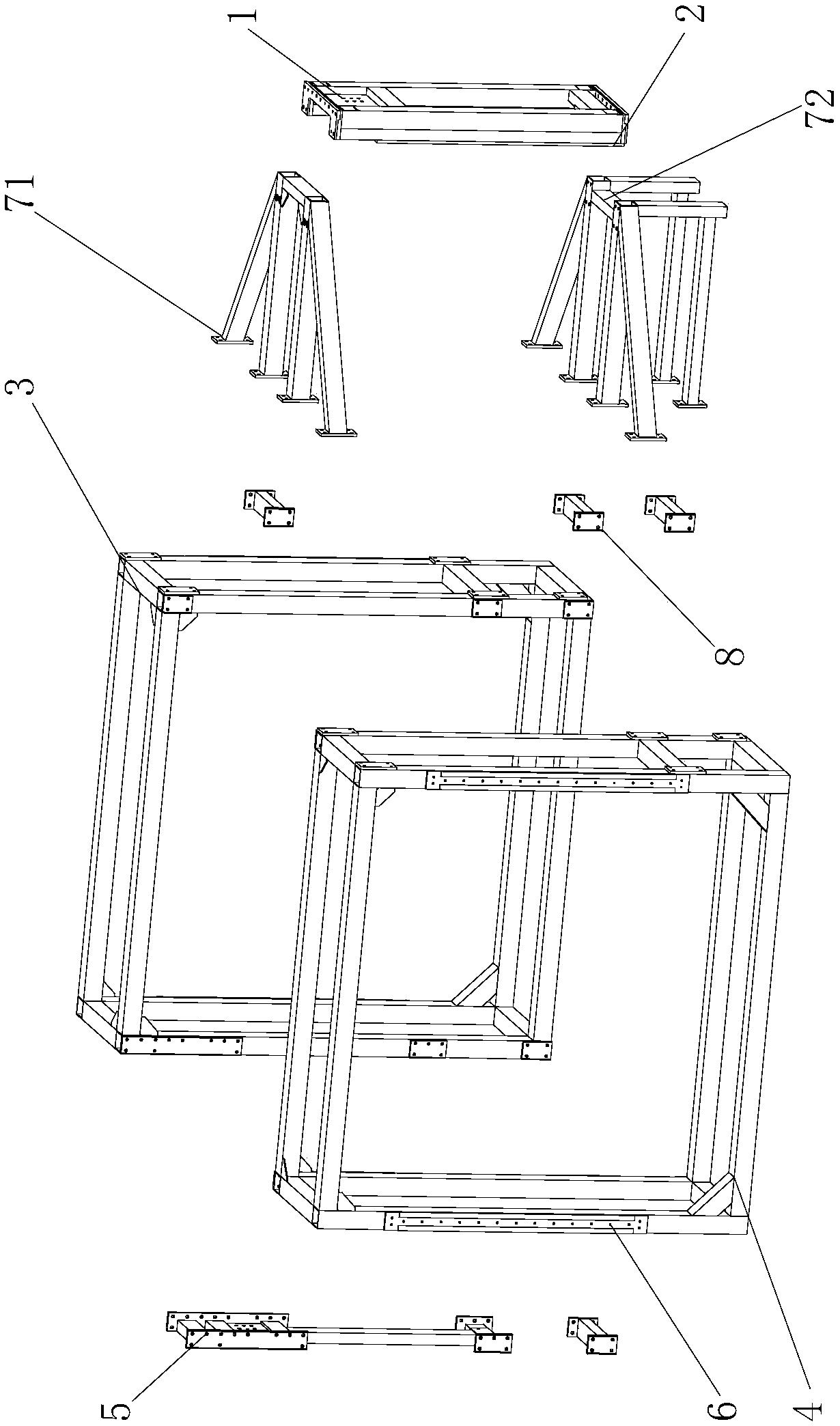

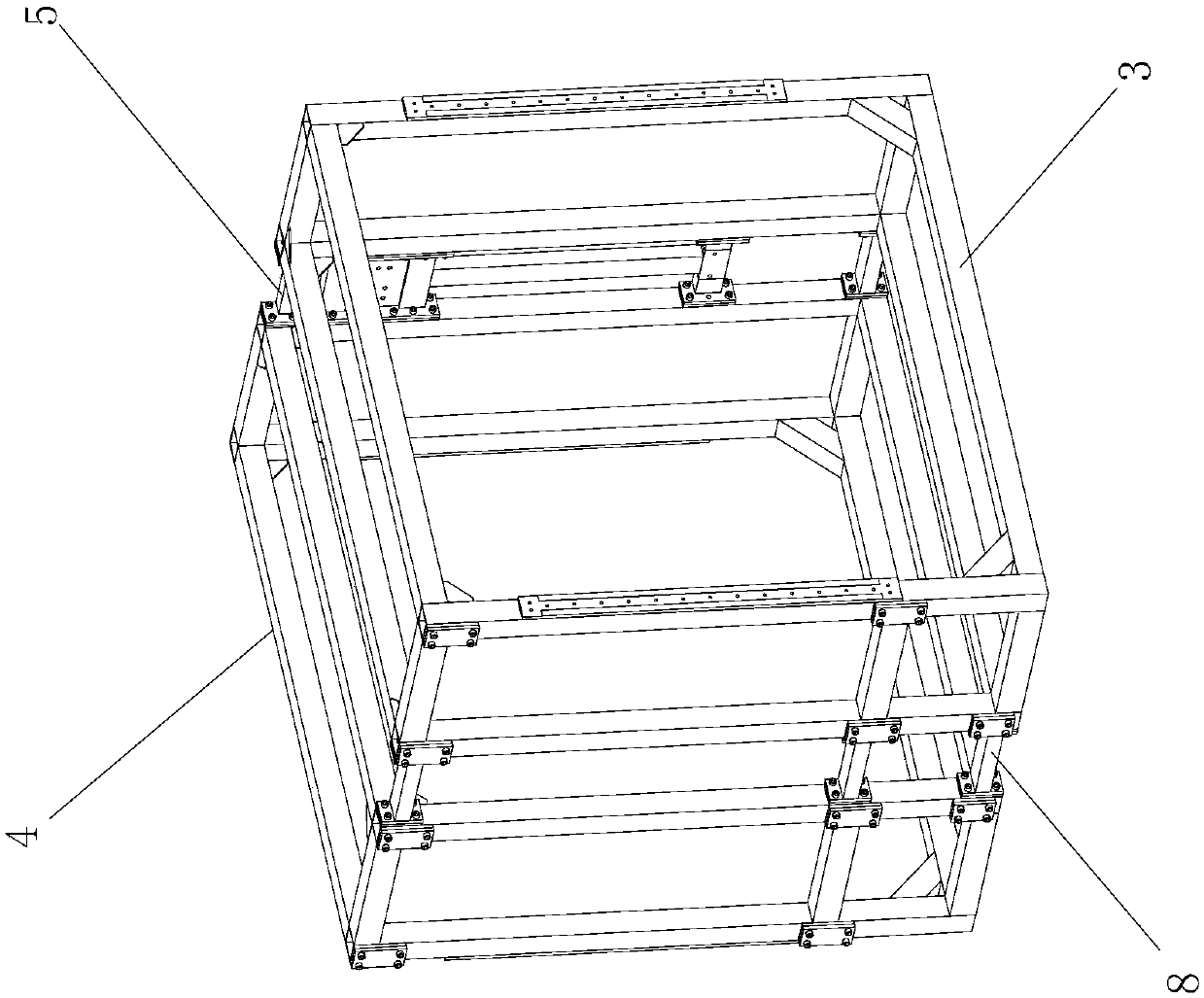

[0028] Example: see Figure 1 to Figure 7 , a main frame of the testing equipment for the seismic performance of a modular combined anti-seismic support and hanger, including:

[0029] The left frame 3 and the right frame 4 form the frame main body for fixing the support hanger. The vertical mobile frame or the horizontal mobile frame is installed on the frame main body. The rear ends of the left frame 3 and the right frame 4 are connected by the lifting motor base 5. The front side of the right frame is provided with frame connection 7 phase connection;

[0030] The frame connection, including the upper frame connection 71 and the lower frame connection 72, is used to connect the left frame 3 and the right frame 4, and each of the upper and lower frame connections has four pins 70 respectively connected to the corresponding connections of the left and right frames 3 and 4 bit;

[0031] The main motor seat 1 is arranged between the upper frame connection 71 and the lower fra...

specific Embodiment approach

[0035] A specific embodiment of the present invention includes left and right frames, the left and right frames are connected, the lifting motor base and the main motor base are connected up and down. The main motor base 1 includes a connecting plate 101 , a connecting plate positioning slot 102 , a motor assembly mounting seat 103 , and a supporting mounting seat 104 . The connecting plate 101 and the connecting plate positioning slot 102 are used for positioning and connecting the main motor base 1 . The motor assembly mount 103 and the support mount 104 are used for mounting and fixing the main motor. The main motor lifting line rail seat 2 is installed on the main motor seat 1. The left and right frames 3, 4 are combined into the frame main body. The lifting motor is fixed on the lifting motor seat 5. The lifting motor base 5 includes a connecting plate 501 , a connecting plate positioning slot 502 , a motor assembly mounting seat 503 , and a supporting mounting seat 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com