A multifunctional intelligent cleaning range hood

A range hood, multi-functional technology, applied in the direction of oil fume removal, household stoves/stoves, heating methods, etc., can solve problems such as uneven oil stains, loss of dynamic balance, and blade shedding, and achieve self-adjusting sensitivity, automatic cleaning, and convenience The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

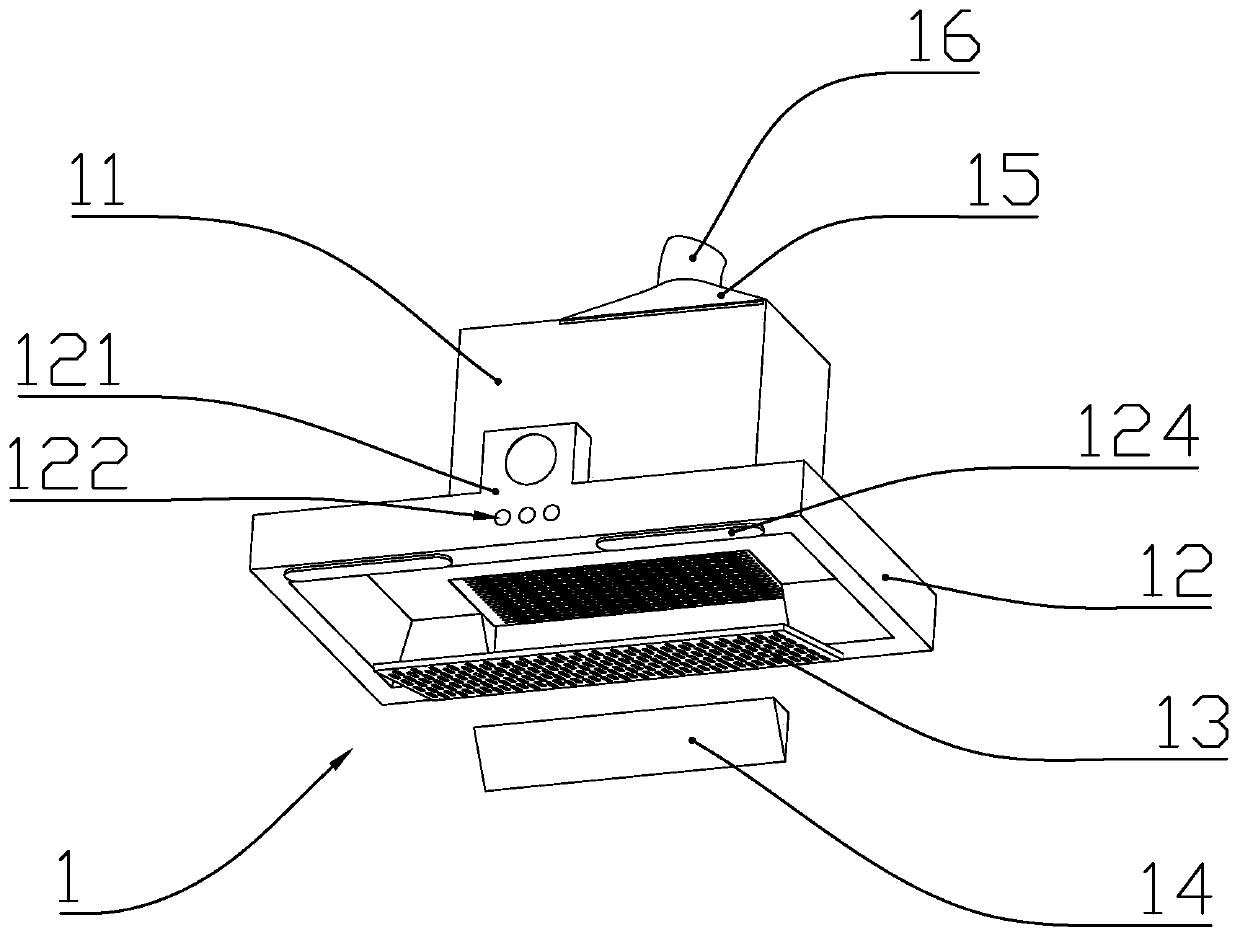

[0044] according to Figure 1 to Figure 8 As shown, the multifunctional intelligent cleaning range hood described in this embodiment includes: a casing 1 and an impeller installed in the casing, and the casing includes an upper casing and a lower casing,

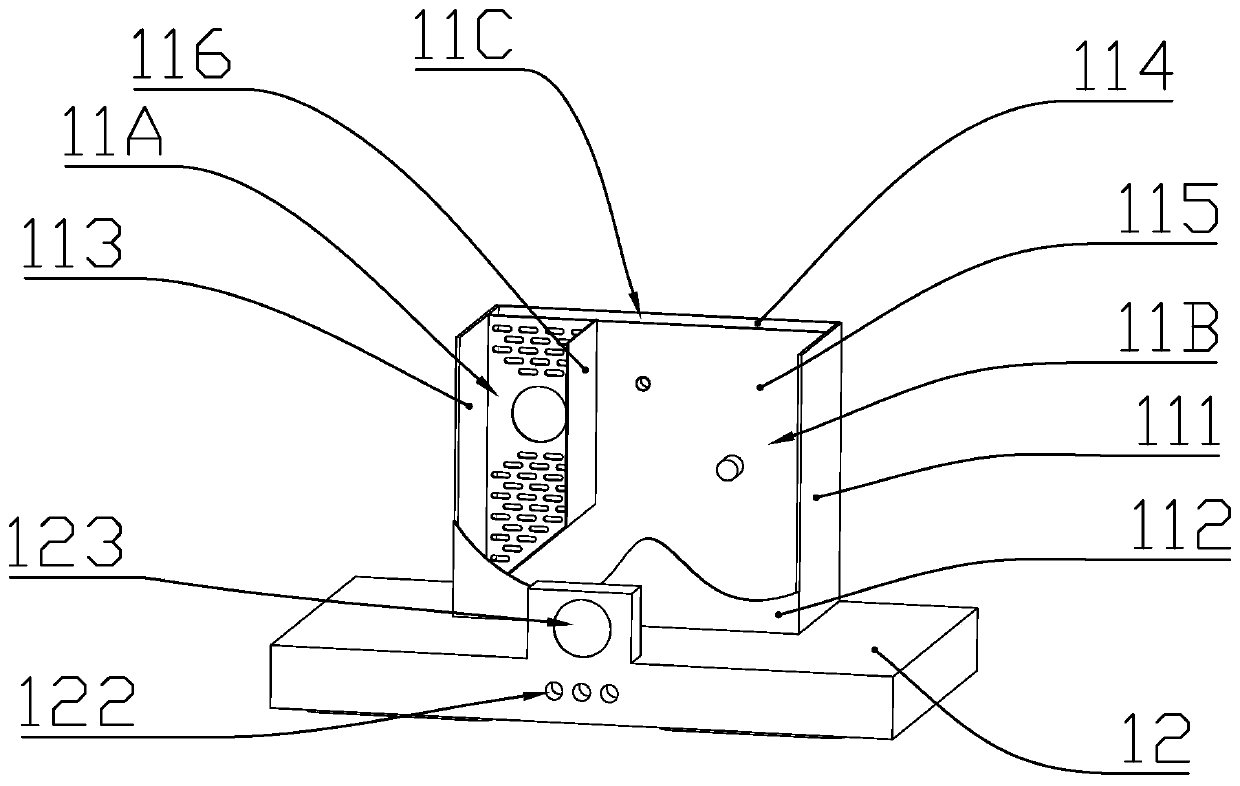

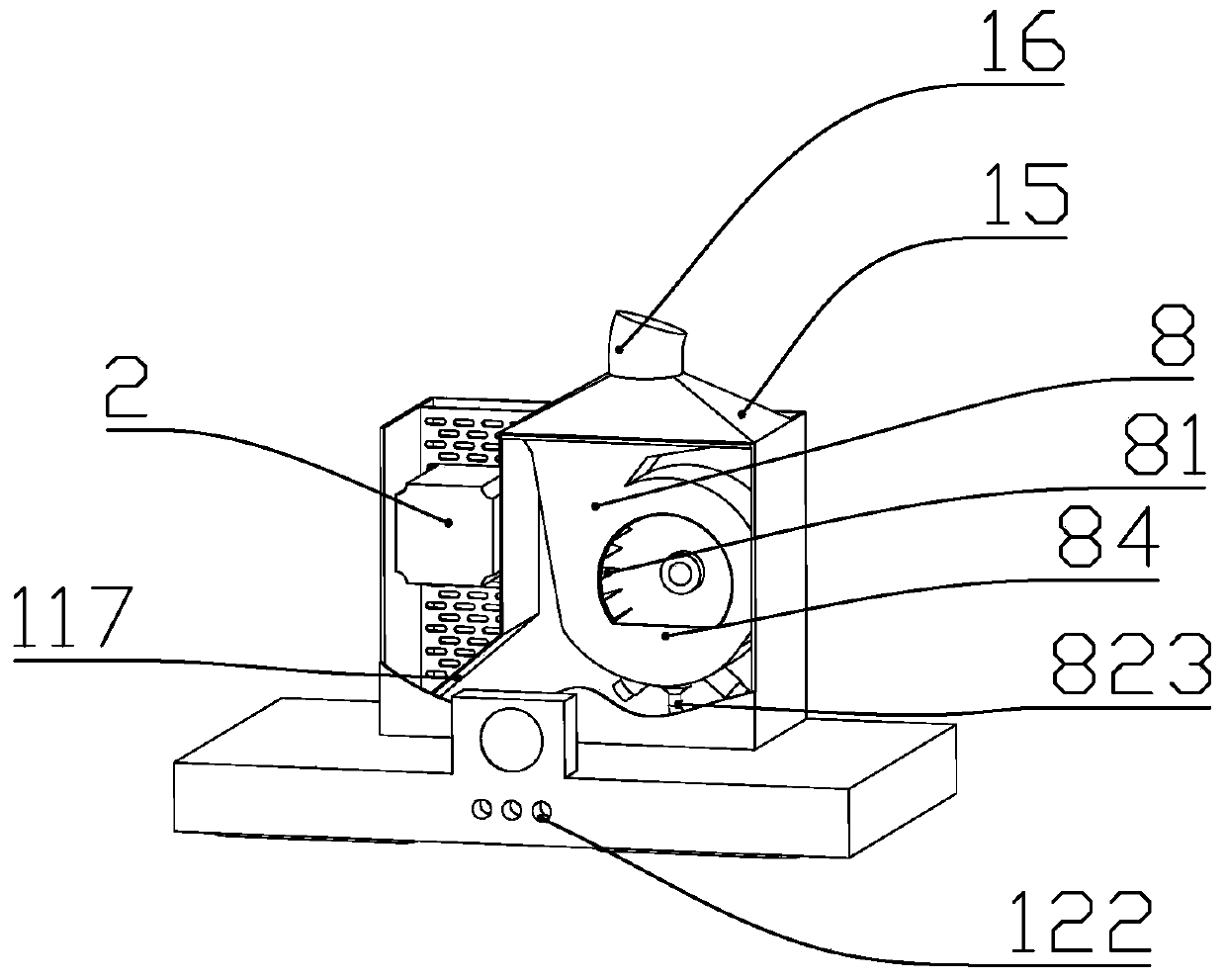

[0045] The upper casing 11 is surrounded by a right side panel 111, a front side panel 112, a left side panel 113 and a rear side panel 114; the distance between the front side panel and the rear side panel is close to one-fifth of the rear side panel The middle partition plate 115 divides the inside of the upper casing into a front cavity and a rear cavity 11C. A vertical partition plate and an inclined partition plate are arranged between the middle partition plate and the front side plate; the vertical partition plate 116 and the inclined partition plate 117 divide the front cavity into a cavity A11A and a cavity B11B. The part of the plate located in the cavity A is provided with a motor installation hole and a heat dis...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is that the control switch includes a rotary adjustment switch and a stepper motor coaxially connected to the knob of the rotary adjustment switch.

[0073] The control switch includes a rotary adjustment switch, and a stepper motor coaxially connected with the knob of the rotary adjustment switch;

[0074] When adjusting a certain rotary adjustment switch, use finger a to block the corresponding induction air outlet, so that the pressure value of the pressure sensor at the corresponding position is greater than the set pressure a, and then use another finger b to block the other two within the set time b. One of the induction air outlets to control the forward and reverse rotation of the stepping motor;

[0075] The induction air outlet blocked by finger a is defined as the target air outlet, and the induction air outlet blocked by finger b is defined as the adjustment air outlet;

[0076] 1) When the adjusting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com