Range hood

A range hood and flue gas technology, applied in the field of "L" type range hood, can solve the problems of limited suction and flue gas escape, and achieve the effect of improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

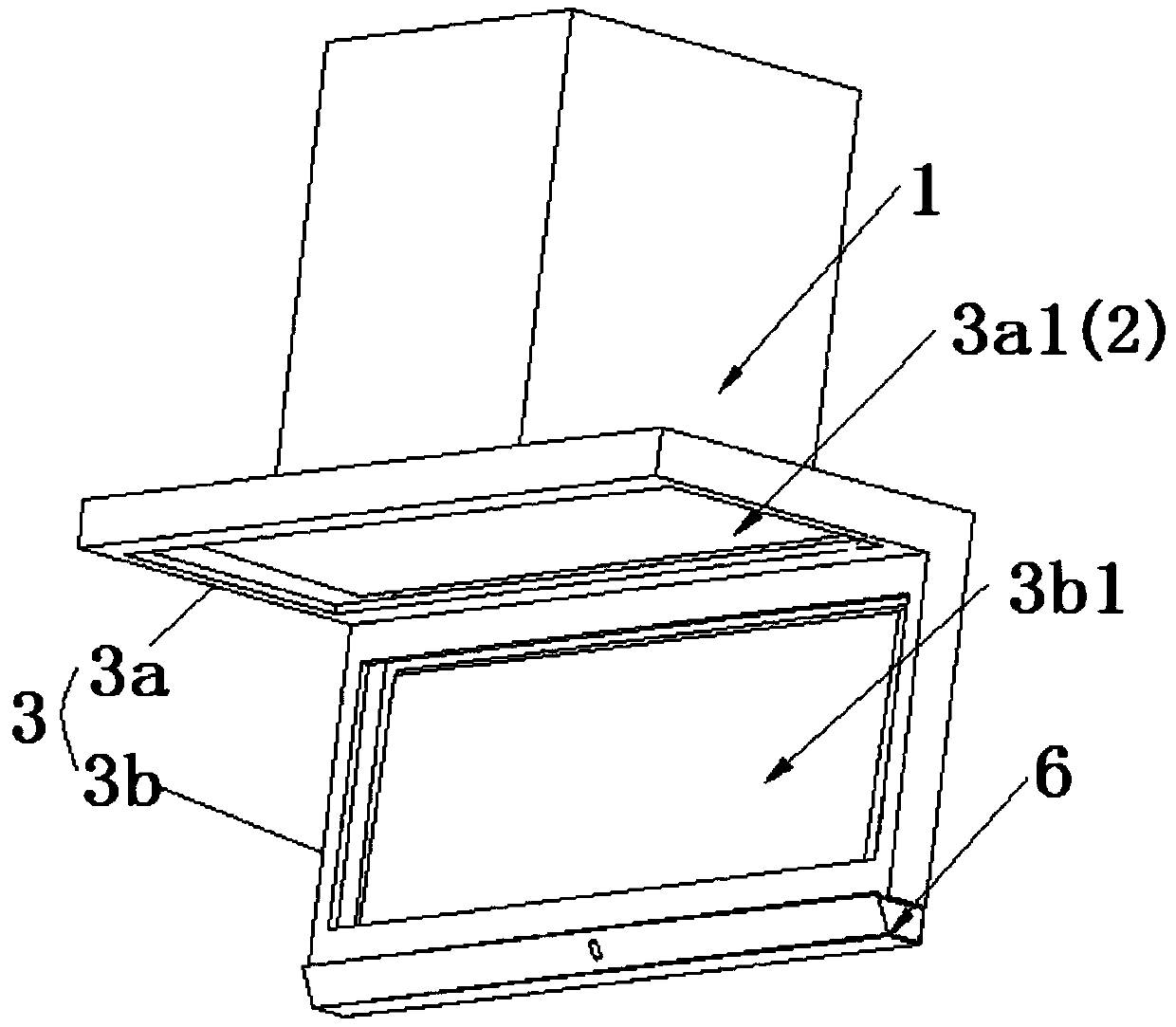

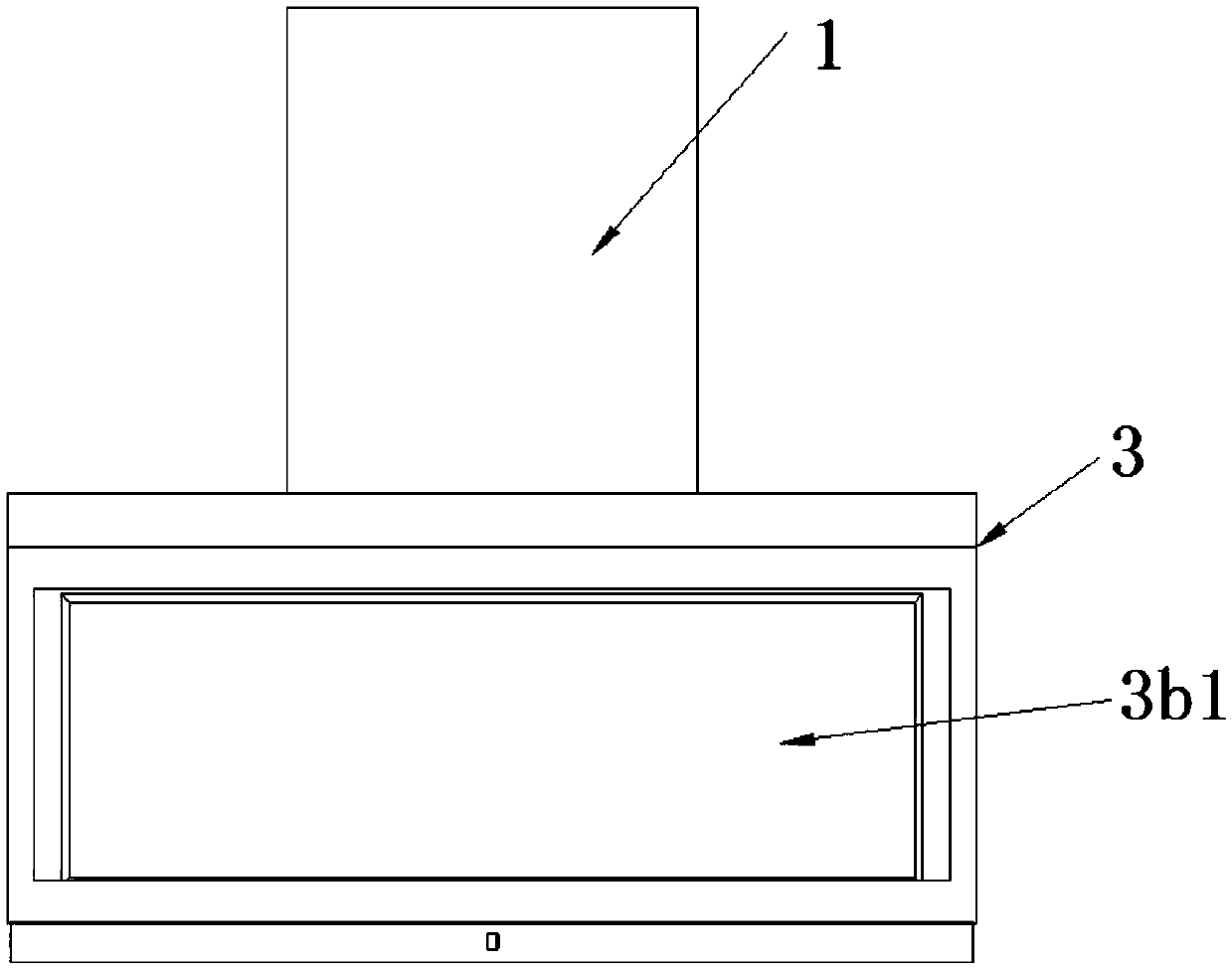

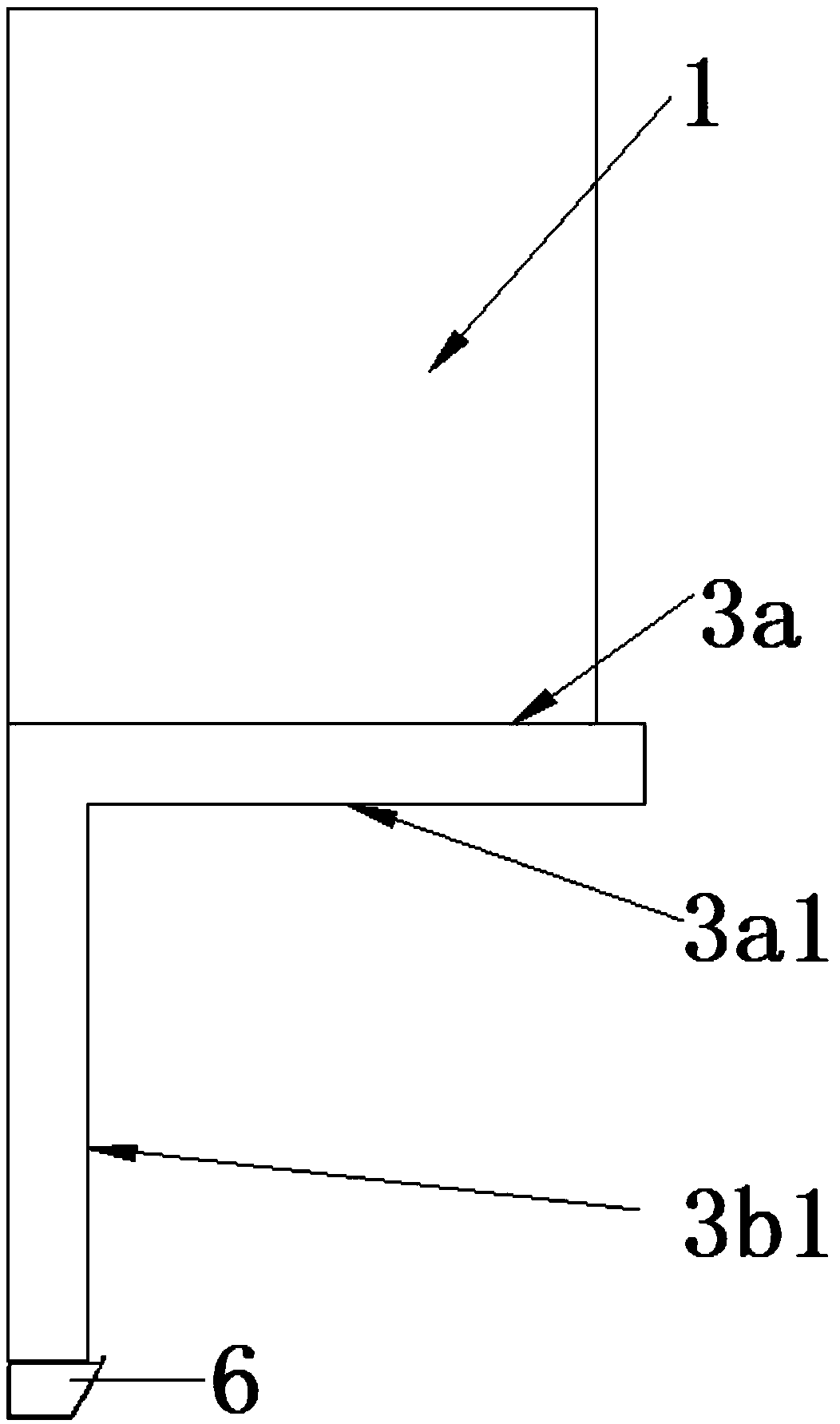

[0037] This embodiment provides a range hood, such as figure 1 , figure 2 with image 3 As shown, it includes: a chassis 1, which is provided with a housing cavity inside, and the housing cavity is provided with an air inlet 2 and an air outlet. Specifically, the air inlet 2 and the air outlet are not shown in the figure; as Figure 4 with Figure 7 As shown, the smoke collecting hood 3 includes a horizontal air-introduction part 3a and a vertical air-induction part 3b arranged at a certain angle to each other, the horizontal air-induction part 3a is provided with a top smoke inlet 3a1, and the vertical air-induction part 3b A side smoke inlet 3b1 is provided, and the smoke flowing out from the horizontal air induction part 3a and the vertical air induction enters the air inlet 2; Figure 4 The blower system 4 shown in the figure is arranged inside the accommodating cavity, including: a wind wheel 4a; a first smoke inlet 4b and a second smoke inlet 4c, which are arranged a...

Embodiment 2

[0049] This embodiment is made on the basis of Embodiment 1. This embodiment specifically provides another setting method of the partition 5. The range hood also includes at least one partition 5, and the partition 5 is installed on the On the wind wheel 4a, the partition plate 5 is arranged between the first smoke inlet 4b and the second smoke inlet 4c, and the above solution is not shown in the accompanying drawings. At the same time, there is a gap between the partition plate 5 and the wind wheel 4a in this embodiment, and the partition plate 5 is arranged on the inner wall of the cabinet 1. By setting the gap, it can be ensured that there will be no contact with the partition plate during the rotation of the wind wheel 4a. Interference between plates 5 occurs.

[0050] Specifically, the partition plate 5 can be provided in multiple pieces, so as to divide the area where the wind wheel 4a is located into a plurality of different areas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com