Bridge Dynamic Weighing Method Based on Distributed Long Gauge Fiber Bragg Grating Sensor

A fiber grating and long gauge technology, which is applied in the field of bridge-type dynamic weighing based on distributed long gauge fiber grating sensors, can solve the problems of system life and accuracy not being guaranteed, electromagnetic interference and chemical erosion, structural cracking failure, etc. problems, to achieve the effect of low-cost large-scale application, auxiliary road traffic management, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

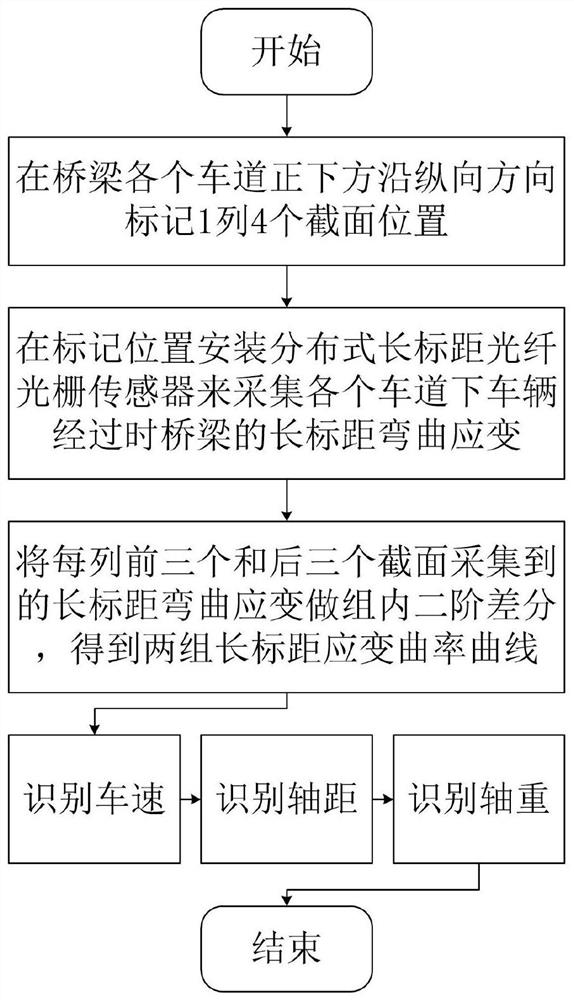

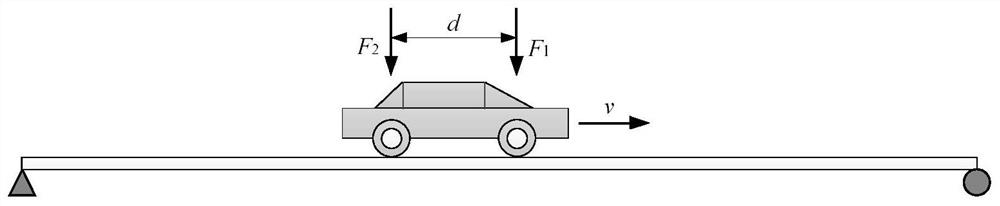

[0035] like figure 1 and 2 As shown, for a bridge under the load of a vehicle, the present invention has the following steps:

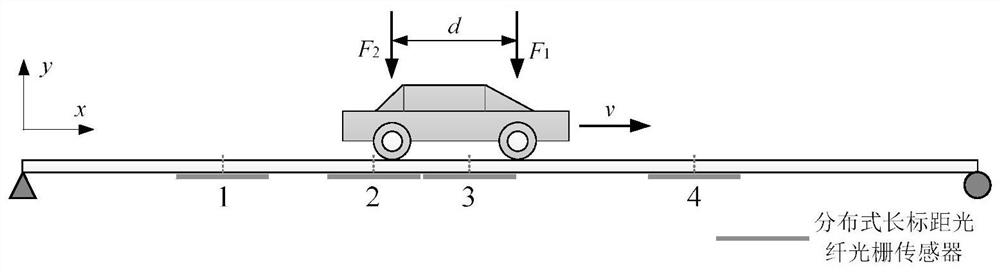

[0036] S1: Mark 1 column and 4 cross-sectional positions directly under each lane of the bridge along the longitudinal direction according to the surface condition of the structure, such as figure 2 Sections 1-4 shown, the relative distance between sections is l 12 , l 23 , l 34 , according to the total number of lanes, mark the corresponding number of cross-sections. For the convenience of description, only a single lane is introduced here;

[0037] S2: set the gauge length to l g The distributed long-gauge fiber grating sensor 1-4 is glued to the corresponding cross-section 1-4, and a column of four sensors is connected in series to form a sensor sequence through a fiber fusion splicer, which is connected to the input end of the fiber opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com