Three-dimensional measuring method and measuring device for converter furnace chamber based on three-dimensional laser radar auxiliary positioning

A three-dimensional laser, auxiliary positioning technology, applied in the field of three-dimensional measurement, can solve the problems of inability to determine the relative position of three-dimensional coordinates, destruction of markers, clumsy self-positioning technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

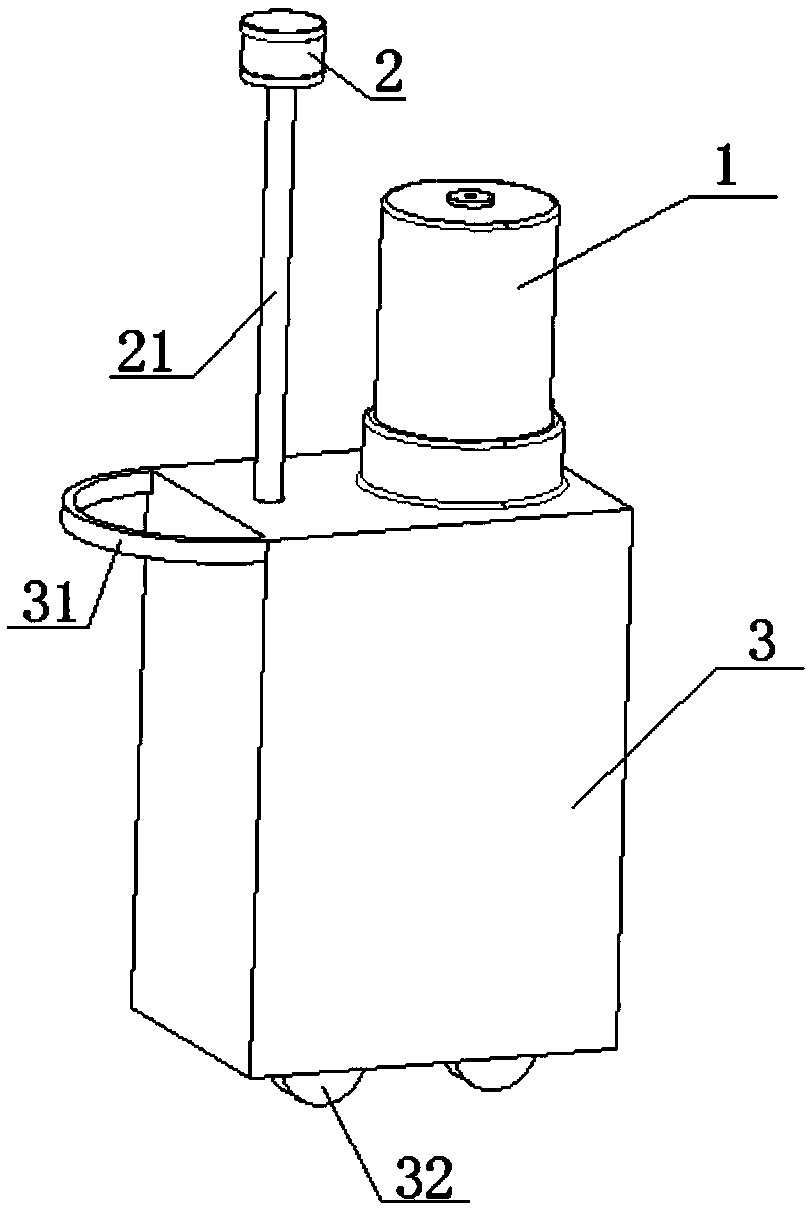

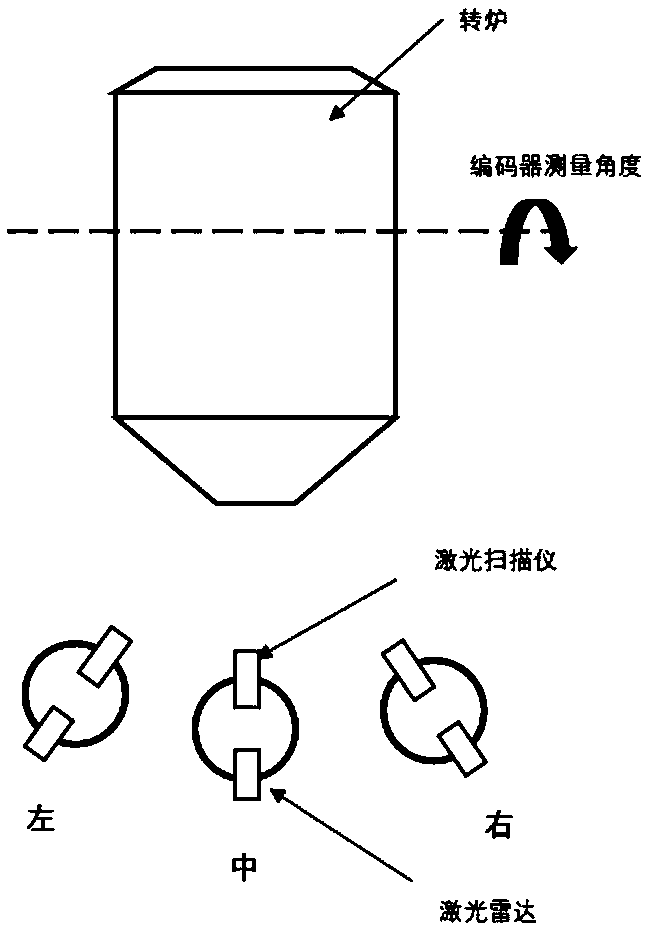

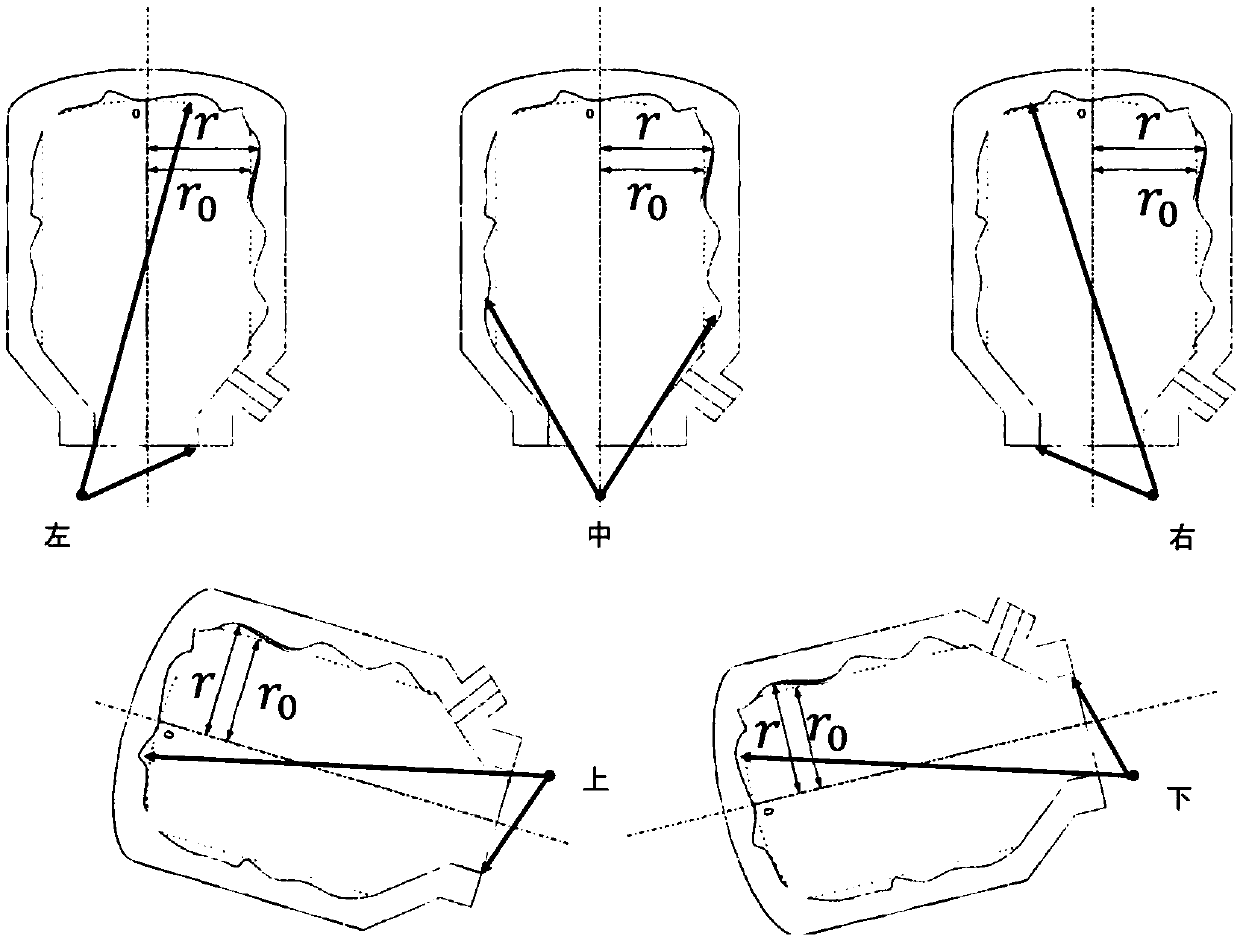

[0095] In the present invention, the three-dimensional laser scanner is fixedly connected with the three-dimensional laser radar, while the three-dimensional laser scanner is moved, the steel factory workshop environment is scanned by the three-dimensional laser radar, and the relative pose of the three-dimensional laser scanner in the three-dimensional space is obtained, and the three-dimensional The three-dimensional point cloud of the converter cavity from various angles of the laser scanner is spliced to obtain a complete three-dimensional point cloud of the converter cavity, which is compared with the CAD model to obtain the thickness change of the converter cavity, real-time monitoring of the wear of the converter cavity, and indicating the need for repair of the converter place to judge whether the converter should be scrapped.

[0096] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0097...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com