Method for preventing intermetallic compounds from agglomeration and growth at high temperature and application

An intermetallic compound and high temperature technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of nanomaterial agglomeration and growth without universal applicability, complex process, etc., to prevent easy agglomeration and growth, and inhibit particle agglomeration , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Make GO plus deionized water to make a 10 mg / ml solution, add H in sequence 2 PtCl 6 , FeCl 3 and PVA so that H 2 PtCl 6 The concentration is 12 mmol / L, FeCl 3 The concentration of 4 mmol / L and the concentration of PVA 20 mg / mL, ultrasonically mixed, then freeze-dried, first at -40 o C for 6 h, and then vacuum-dried for 24 h. The resulting product was heated at 8% H 2 / High temperature quenching treatment in Ar environment, calcination temperature 600 o C, time 6h. The product is filtered, washed and then dried to obtain the fuel cell electrode active material Pt 3 Fe / C.

Embodiment 2

[0035] Make GO plus deionized water to make a 10 mg / ml solution, add H in sequence 2 PtCl 6 , CoCl 2 and PVA so that H 2 PtCl 6 The concentration is 12 mmol / L, CoCl 2 The concentration of 4 mmol / L and the concentration of PVA is 20 mg / mL, ultrasonically mixed, then freeze-dried, at -40 o C for 6 h, and vacuum-dried for 24 h. The resulting product was heated at 8% H 2 / High temperature quenching treatment in Ar environment, calcination temperature 700 o C, time 6h. The product is filtered, washed and then dried to obtain the fuel cell electrode active material Pt 3 Co / C.

Embodiment 3

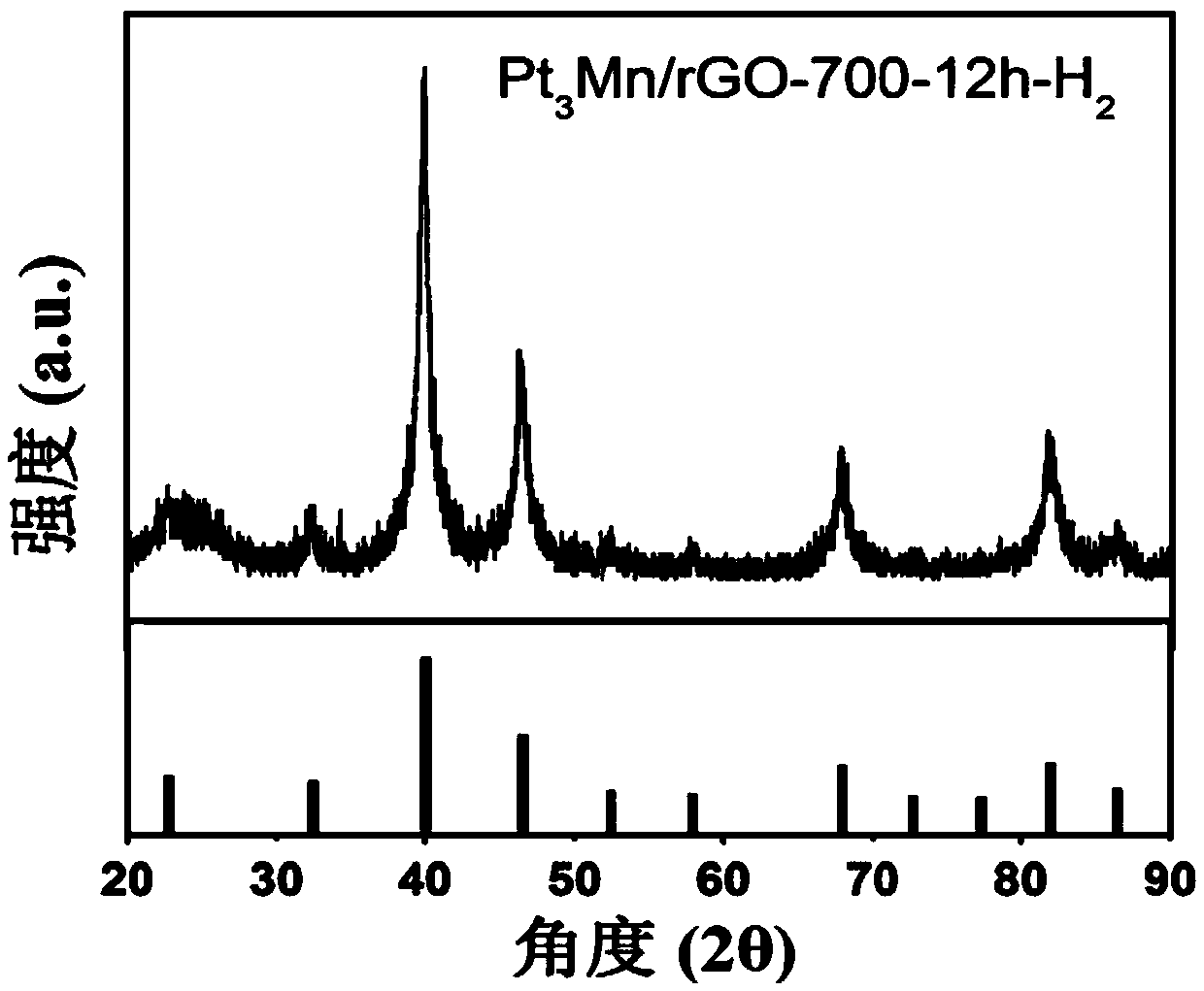

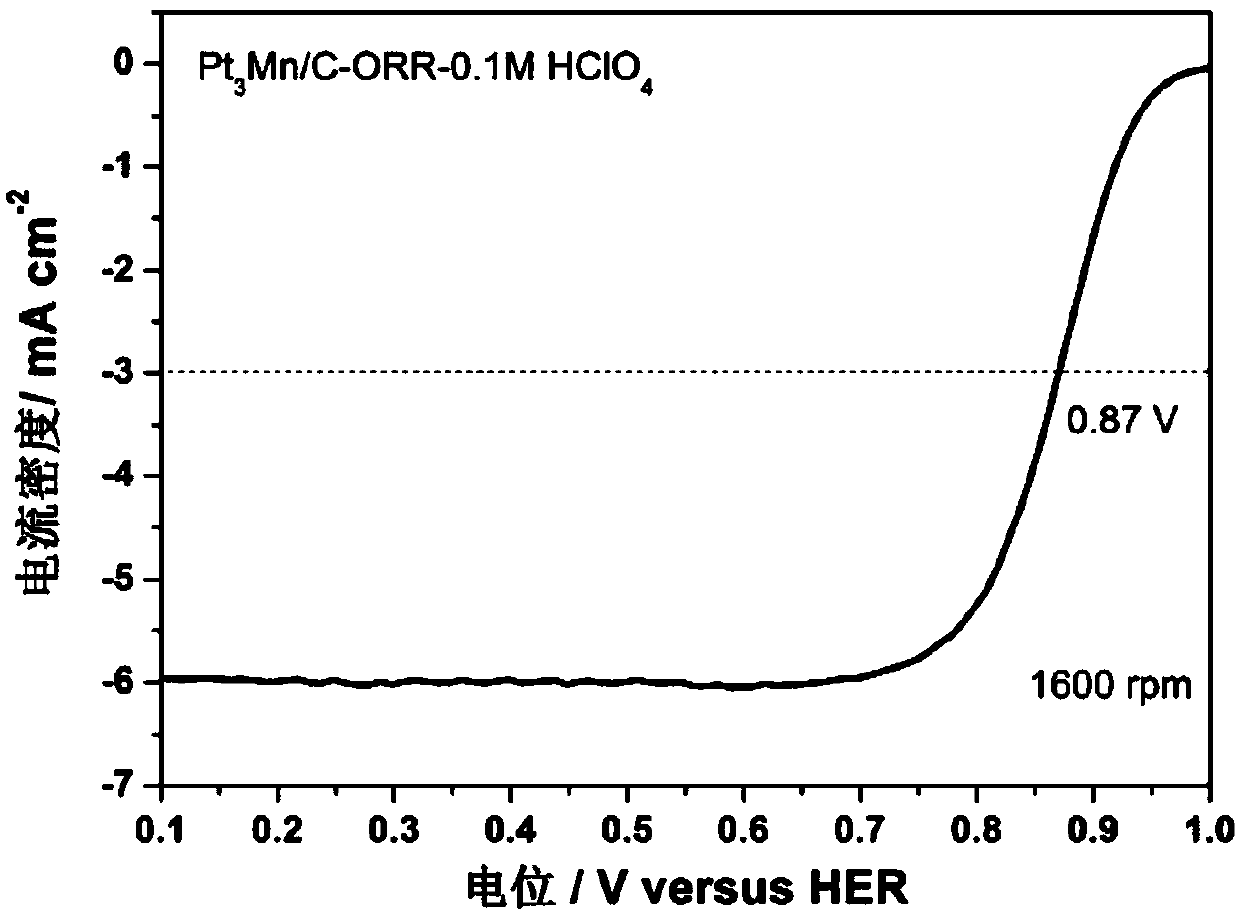

[0037] Add XC-72 and deionized water to make a 10 mg / ml solution, add H in sequence 2 PtCl 6 , MnCl 2 and PVA so that H 2 PtCl 6 The concentration is 12 mmol / L, MnCl 2 The concentration of 4 mmol / L and the concentration of PVA is 20 mg / mL, ultrasonically mixed, then freeze-dried, at -40 o C for 6 h, and vacuum-dried for 24 h. The resulting product was heated at 8% H 2 / High temperature quenching treatment in Ar environment, calcination temperature 700 o C, time 6h. The product is filtered, washed and then dried to obtain the fuel cell electrode active material Pt 3 Mn / C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com