Preparation method of high-surface-area aluminum oxide micro powder

A technology of alumina micropowder and high specific surface, which is applied in the field of materials, can solve the problems of unresolved contradiction between micropowder and high specific surface, high-salt wastewater cannot be recycled, environmental risks and high production costs, and achieve the purpose of inhibiting particle agglomeration, inhibiting Capillary collapse and the effect of breaking through technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

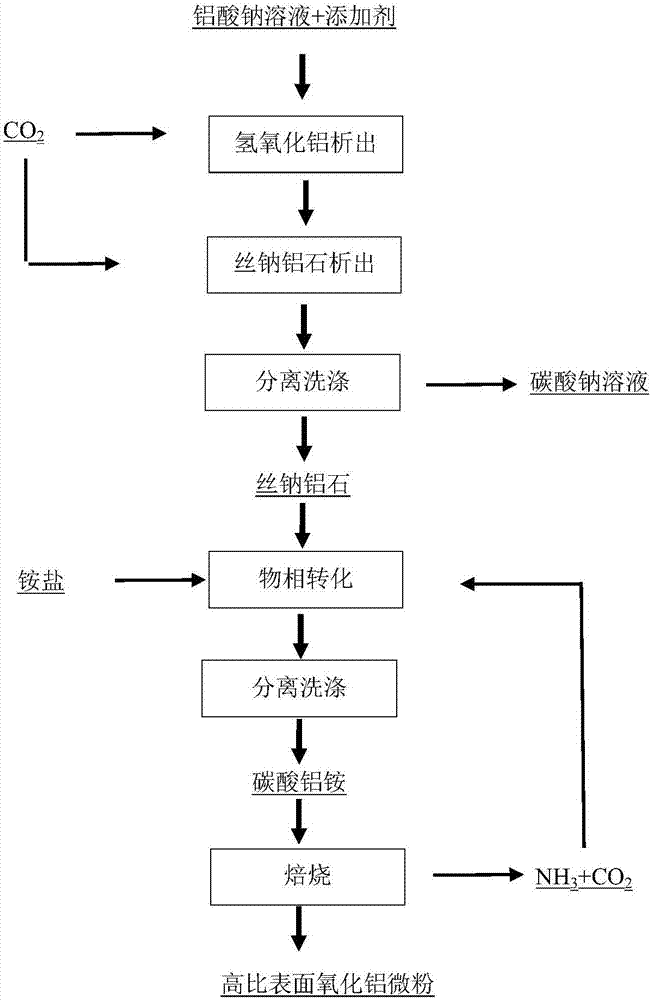

[0037] A kind of preparation method of high specific surface alumina micropowder of the present invention, see figure 1 , including the following steps:

[0038] (1) At 35°C, in 500 mL sodium aluminate solution (Na 2 o K (caustic) = 10 g / L, Al 2 o 3 =12.2g / L, caustic ratio α K =1.4), add 10 ppm stearic acid and polyethylene glycol mixture (the mass ratio of stearic acid and polyethylene glycol is 1:1), and introduce 10% (volume percentage) of CO 21 h, aluminum hydroxide slurry was obtained.

[0039] (2) At 50°C, continue to feed 10% CO into the aluminum hydroxide slurry 2 4 h, to get the snarbite slurry. Vacuum filtration of the sponsonite slurry, separating the filter residue and filtrate, taking the filter residue and washing it fully with hot water to obtain the sponsonite. The filtrate is the sodium carbonate solution, and the sodium carbonate solution is reacted with lime to generate sodium hydroxide solution and calcium carbonate, and the evaporated and concentr...

Embodiment 2

[0044] A kind of method of high specific surface alumina micropowder of the present invention, see figure 1 , including the following steps:

[0045] (1) At 65°C, in 500 mL sodium aluminate solution (Na 2 o K (caustic) = 130 g / L, Al 2 o 3 =120g / L, caustic ratio α K =1.8), add 200 ppm stearic acid, mannitol and polyethylene glycol mixture (the mass ratio of stearic acid, mannitol and polyethylene glycol is 3:1:6), and introduce 30% CO 2 5 h, aluminum hydroxide slurry was obtained. The aluminum hydroxide slurry is subjected to solid-liquid separation, the filter residue is washed with hot water to obtain aluminum hydroxide, and the filtrate is sodium aluminate solution.

[0046] (2) At 70°C, add the aluminum hydroxide in step (1) to 100 g / L sodium carbonate solution, and pass in 30% CO 2 6h, to obtain the sialonite slurry. Vacuum filtration of the sponsonite slurry, separating the filter residue and filtrate, taking the filter residue and washing it fully with hot wate...

Embodiment 3

[0051] A kind of method of high specific surface alumina micropowder of the present invention, see figure 1 , including the following steps:

[0052] (1) At 55°C, in 500 mL sodium aluminate solution (Na 2 o K (caustic) = 50 g / L, Al 2 o 3 =49.8g / L, caustic ratio α K =1.6), add 50 ppm stearic acid and polyethylene glycol mixture (the mass ratio of stearic acid and polyethylene glycol is 1:2), and introduce 15% CO 2 5 h, aluminum hydroxide slurry was obtained.

[0053] (2) At 50°C, continue to feed CO into the aluminum hydroxide slurry 2 6 h, to get the sarsonite slurry. Vacuum filtration of the sponsonite slurry, separating the filter residue and filtrate, taking the filter residue and washing it fully with hot water to obtain the sponsonite. The filtrate is sodium carbonate solution. The sodium carbonate solution is reacted with lime to generate sodium hydroxide solution and calcium carbonate. The evaporated and concentrated sodium hydroxide solution dissolves aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com