Orthopedic clinical fracture continuation device

A technology for bone replacement and orthopedics, which is applied in the field of bone replacement devices for clinical fractures in orthopedics. It can solve the problems of aggravating the disease, suffering patients, increasing the labor intensity of medical staff, etc., and achieve the effect of reducing labor intensity and avoiding pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

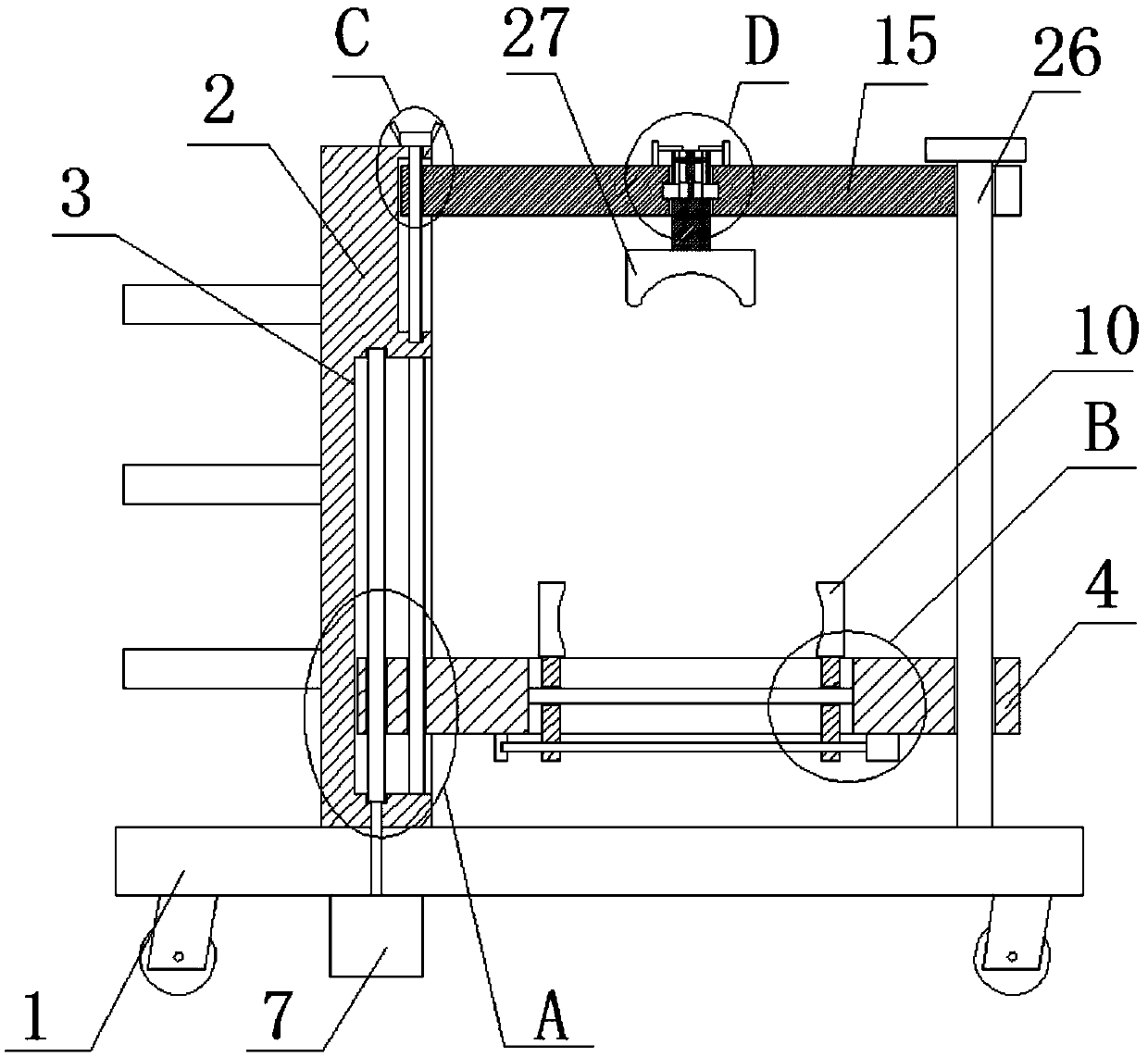

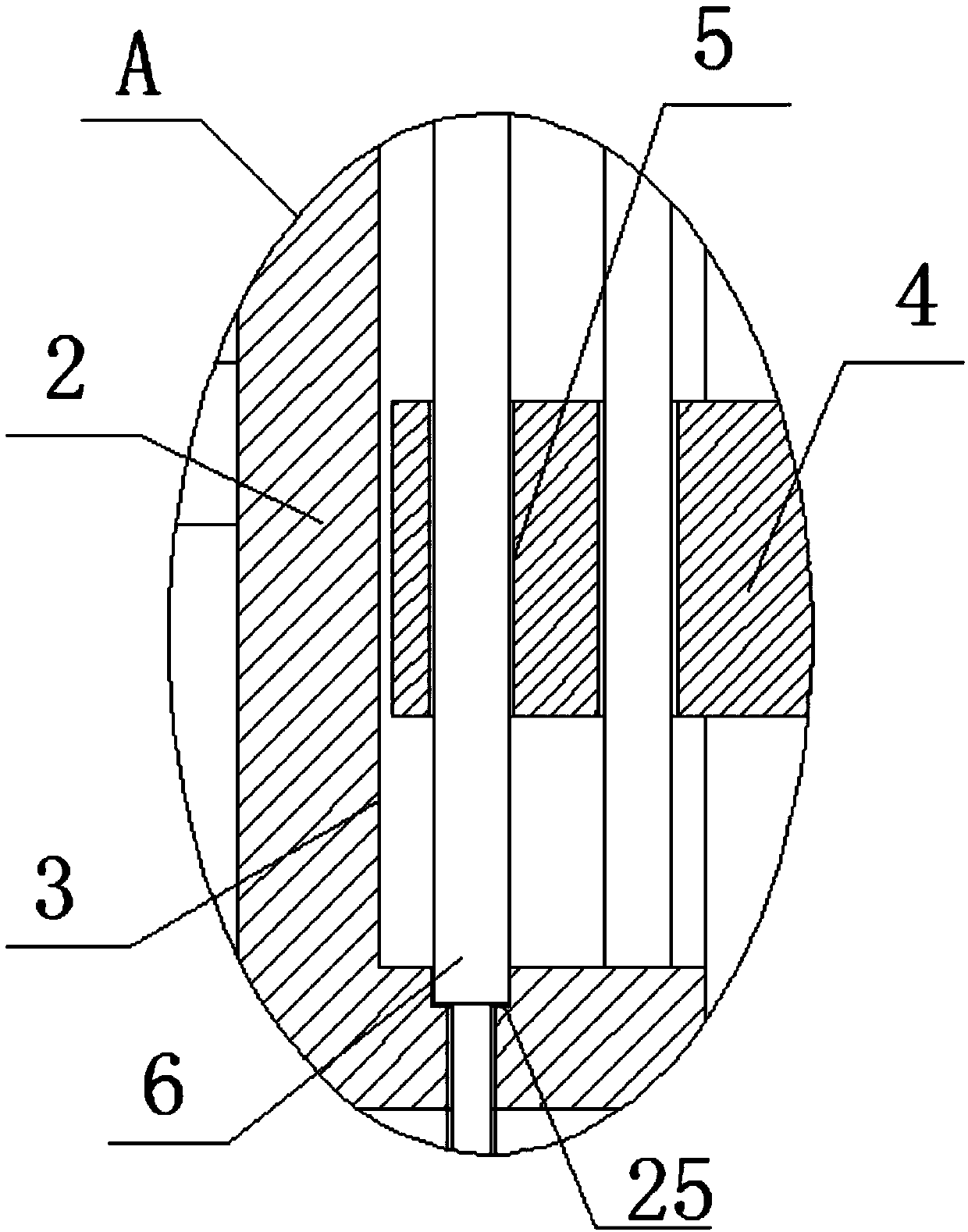

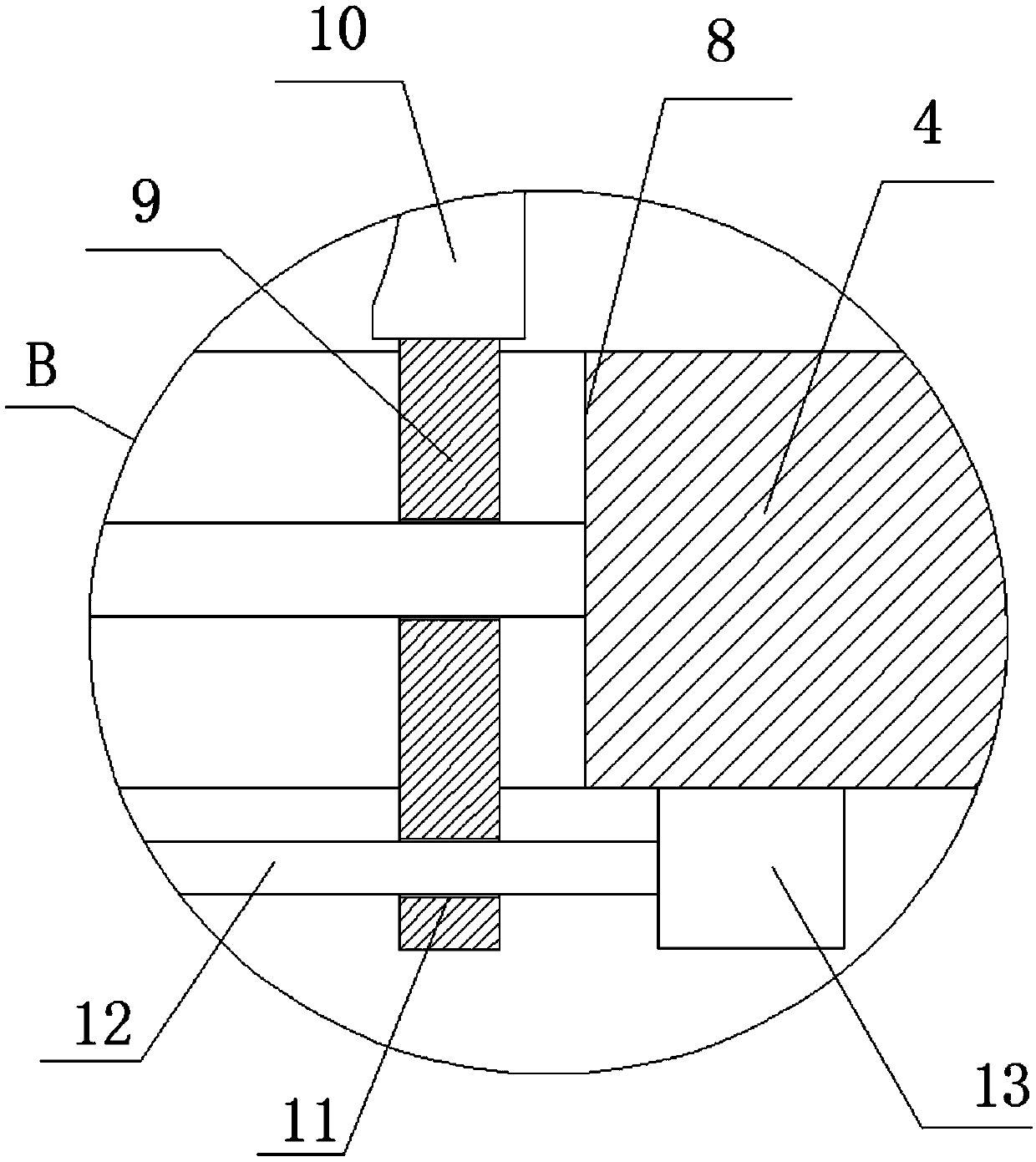

[0023] refer to Figure 1-5, the present embodiment proposes a kind of orthopedic clinical fracture bone device, including a base 1, the top of the base 1 is welded with a vertical plate 2, a groove 3 is opened on one side of the vertical plate 2, and an auxiliary device is slidably installed in the groove 3. Plate 4, the top of the auxiliary plate 4 is welded with a first threaded hole 5, the internal thread of the first threaded hole 5 is installed with a ball screw 6, the bottom of the base 1 is welded with a first forward and reverse motor 7, and the first forward and reverse motor The output shaft of 7 is welded to the bottom of the ball screw 6, and the top of the auxiliary plate 4 is provided with a sliding hole 8, and two moving rods 9 are slidably installed in the sliding hole 8, and the tops of the two moving rods 9 are welded with clamping Seat 10, the two clamping seats 10 are compatible, one side of the two moving rods 9 is provided with a second threaded hole 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com