Wood door processing technology

A processing technology and technology for wooden doors, which are used in wood processing appliances, wood heating, wood treatment, etc., can solve the problems that the processing technology of wooden doors cannot meet the requirements of use, the wood cannot fully absorb flame retardants, and the use time of wooden doors is not long. Achieve the effect of shortening drying time, increasing degreasing effect, and obvious flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

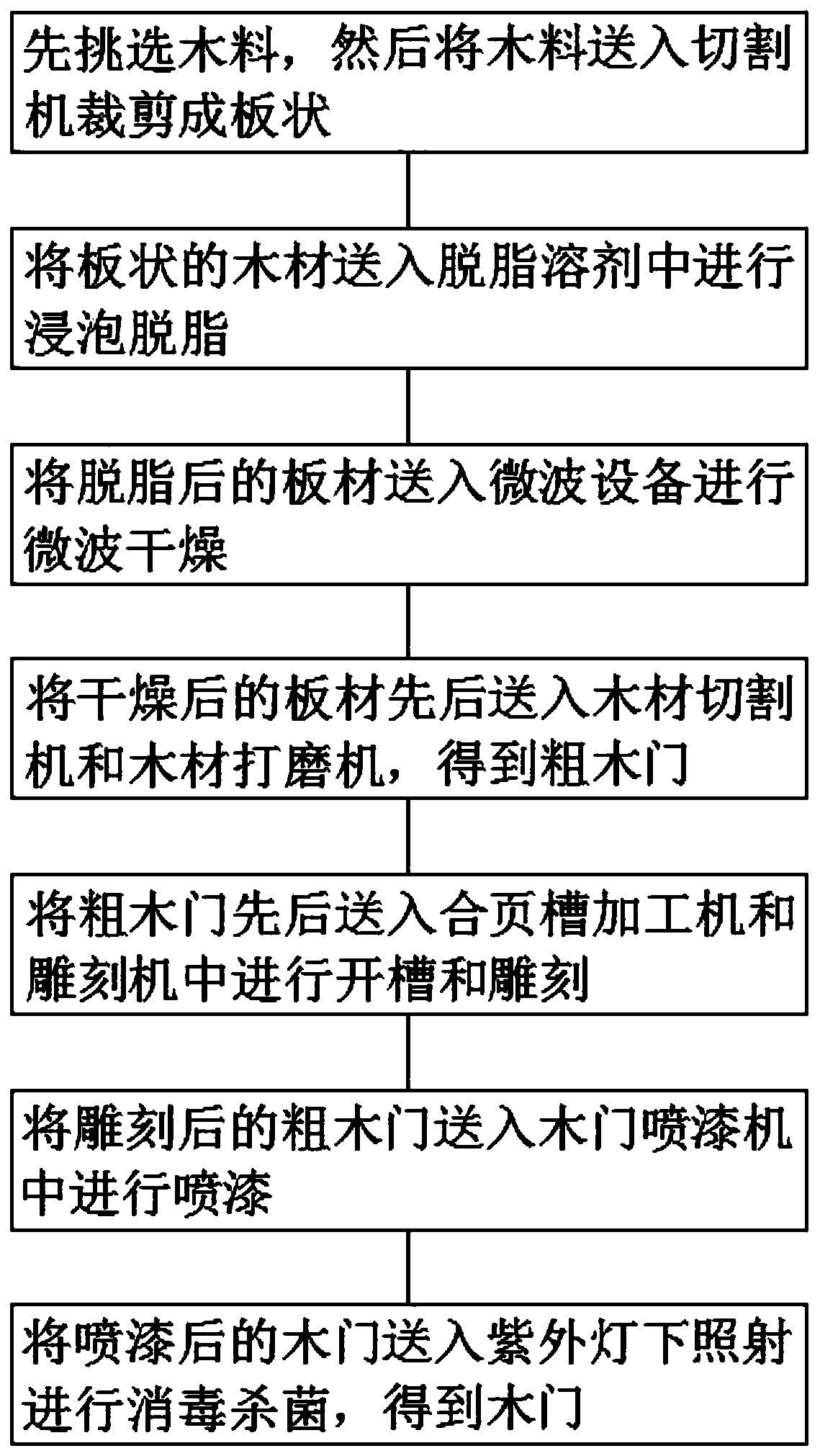

Image

Examples

Embodiment 1

[0030] (1) Select the wood first, then send the selected wood into the wood cutting machine and cut it into a plate shape. The length of the cut plate is 10mm longer than the specified wooden door length, and the width of the cut plate is wider than the specified wooden door width. 8mm, the thickness of the cut plate is 5mm thicker than the specified wooden door thickness;

[0031] (2), the board-shaped wood is sent into the degreasing solvent to soak and degrease, and the degreasing solvent adopts a concentration of 2% sodium hydroxide solution, and the degreasing time of the board is 6 hours, and the board needs to be degreased before using the degreasing solvent The plate is pretreated, and the steps of pretreatment are:

[0032] ①. Soak the plate in cold water for 24 hours;

[0033] ②. After soaking in cold water, raise the temperature of the cold water to 60°C and maintain the water temperature for 24 hours;

[0034] (3) Send the degreased board into microwave equipment...

Embodiment 2

[0040] (1) Select the wood first, then send the selected wood into the wood cutting machine and cut it into a plate shape. The length of the cut plate is 10mm longer than the specified wooden door length, and the width of the cut plate is wider than the specified wooden door width. 8mm, the thickness of the cut plate is 5mm thicker than the specified wooden door thickness;

[0041] (2), the board-shaped wood is sent into the degreasing solvent to soak and degrease, and the degreasing solvent adopts a concentration of 2% sodium hydroxide solution, and the degreasing time of the board is 6 hours, and the board needs to be degreased before using the degreasing solvent The plate is pretreated, and the steps of pretreatment are:

[0042] ①. Soak the plate in cold water for 24 hours;

[0043] ②. After soaking in cold water, raise the temperature of the cold water to 70°C and maintain the water temperature for 24 hours;

[0044] (3) Send the degreased board into microwave equipment...

Embodiment 3

[0050] (1) Select the wood first, then send the selected wood into the wood cutting machine and cut it into a plate shape. The length of the cut plate is 10mm longer than the specified wooden door length, and the width of the cut plate is wider than the specified wooden door width. 8mm, the thickness of the cut plate is 5mm thicker than the specified wooden door thickness;

[0051] (2), the board-shaped wood is sent into the degreasing solvent to soak and degrease, and the degreasing solvent adopts a concentration of 2% sodium hydroxide solution, and the degreasing time of the board is 6 hours, and the board needs to be degreased before using the degreasing solvent The plate is pretreated, and the steps of pretreatment are:

[0052] ①. Soak the plate in cold water for 24 hours;

[0053] ②. After soaking in cold water, raise the temperature of the cold water to 80°C and maintain the water temperature for 24 hours;

[0054] (3) Send the degreased board into microwave equipment f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com