Stemming processing device

A technology of processing device and tap mud, which is applied in discharge device, clay preparation device, clay mixing device, etc., can solve the problems of difficult sealing of air leakage and water leakage, affecting engineering, long time, etc., and achieve convenient and fast sealing, Strengthen the hardness of the clay and achieve the effect of single-person operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

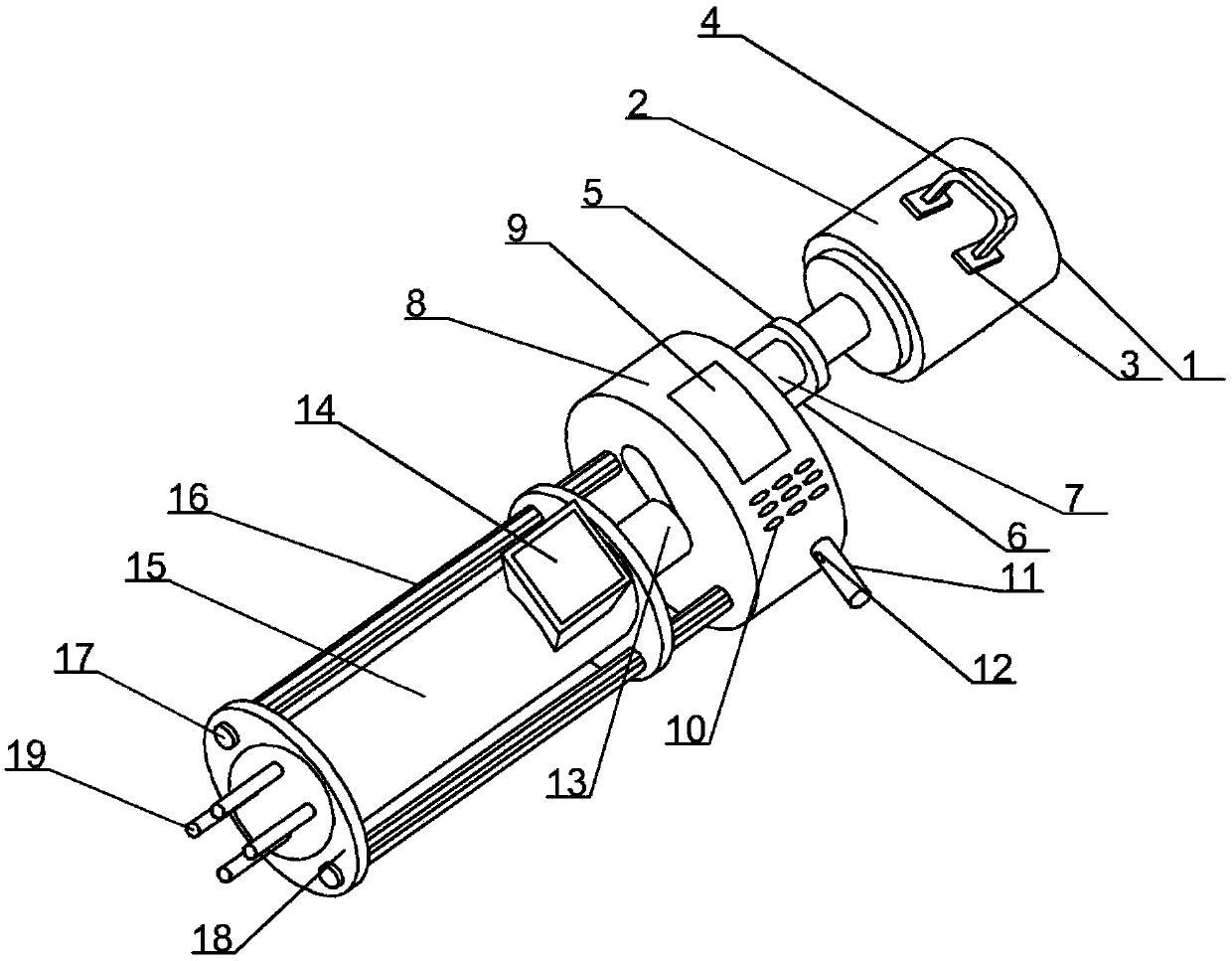

[0017] A gun mud processing device and its use method, a gun mud processing device, comprising a gun mud device main body 1, a motor 2 is provided on the gun mud device main body 1, a fixed buckle 3 is provided on the surface of the motor 2, and a fixed buckle 3 A hand handle 4 is connected to the top, a protective washer 5 is provided on the left side of the motor 2, a protective shell 6 is provided on the left side of the protective washer 5, a transmission shaft 7 is provided inside the protective shell 6, and a speed change control box 8 is provided on the left side of the protective shell 6. The variable speed control box 8 is provided with a display 9, the lower side of the display 9 is provided with a control button 10, the lower side of the control button 10 is provided with a grip handle 11, and the grip handle 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com