Product and waste separation device of plastic piece

A technology for separating equipment and plastic parts, applied in the field of injection molding parts production equipment, can solve the problems of low efficiency, heavy workload, low injection molding efficiency, etc., and achieve the effect of not easy to shift and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

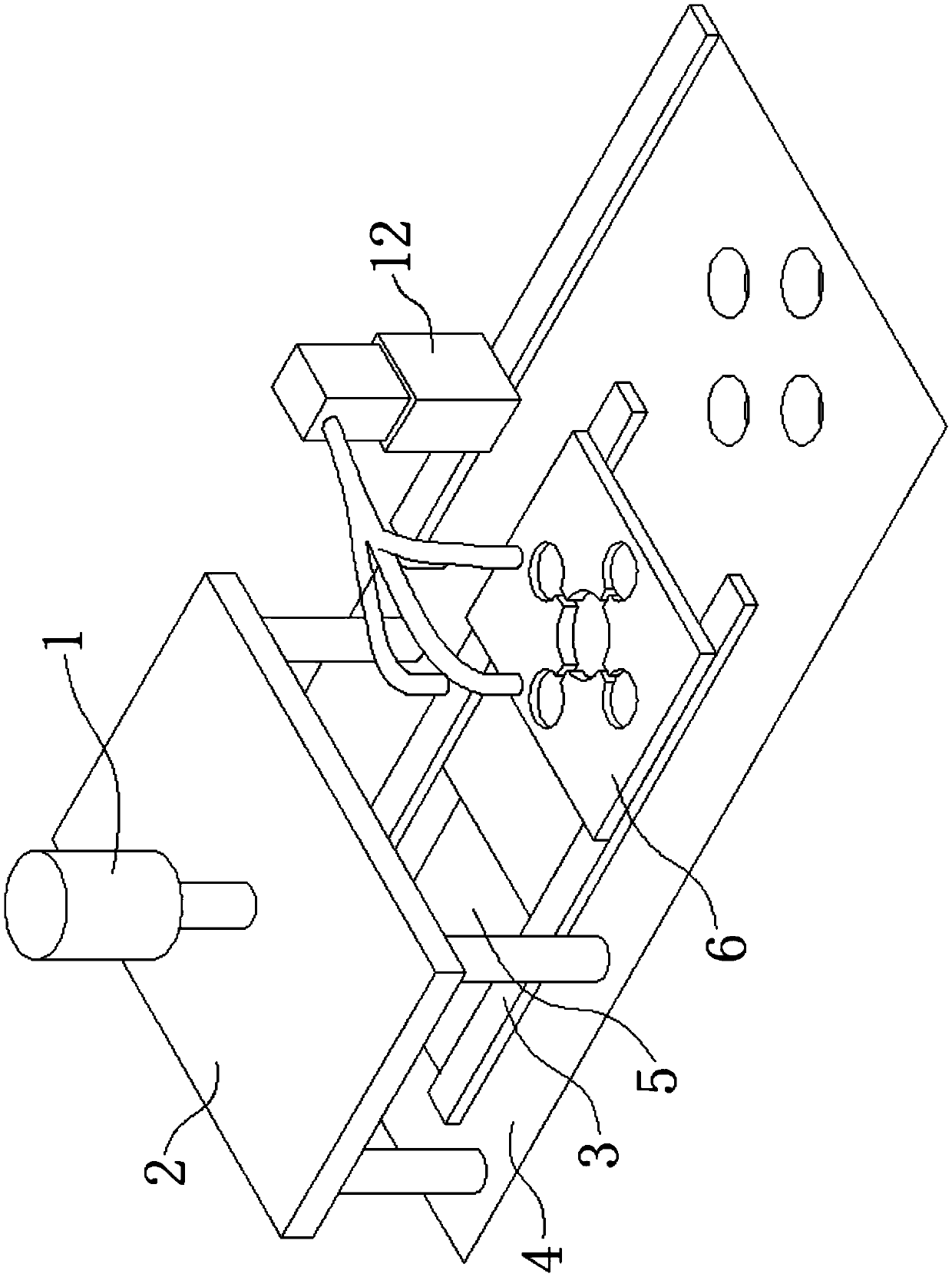

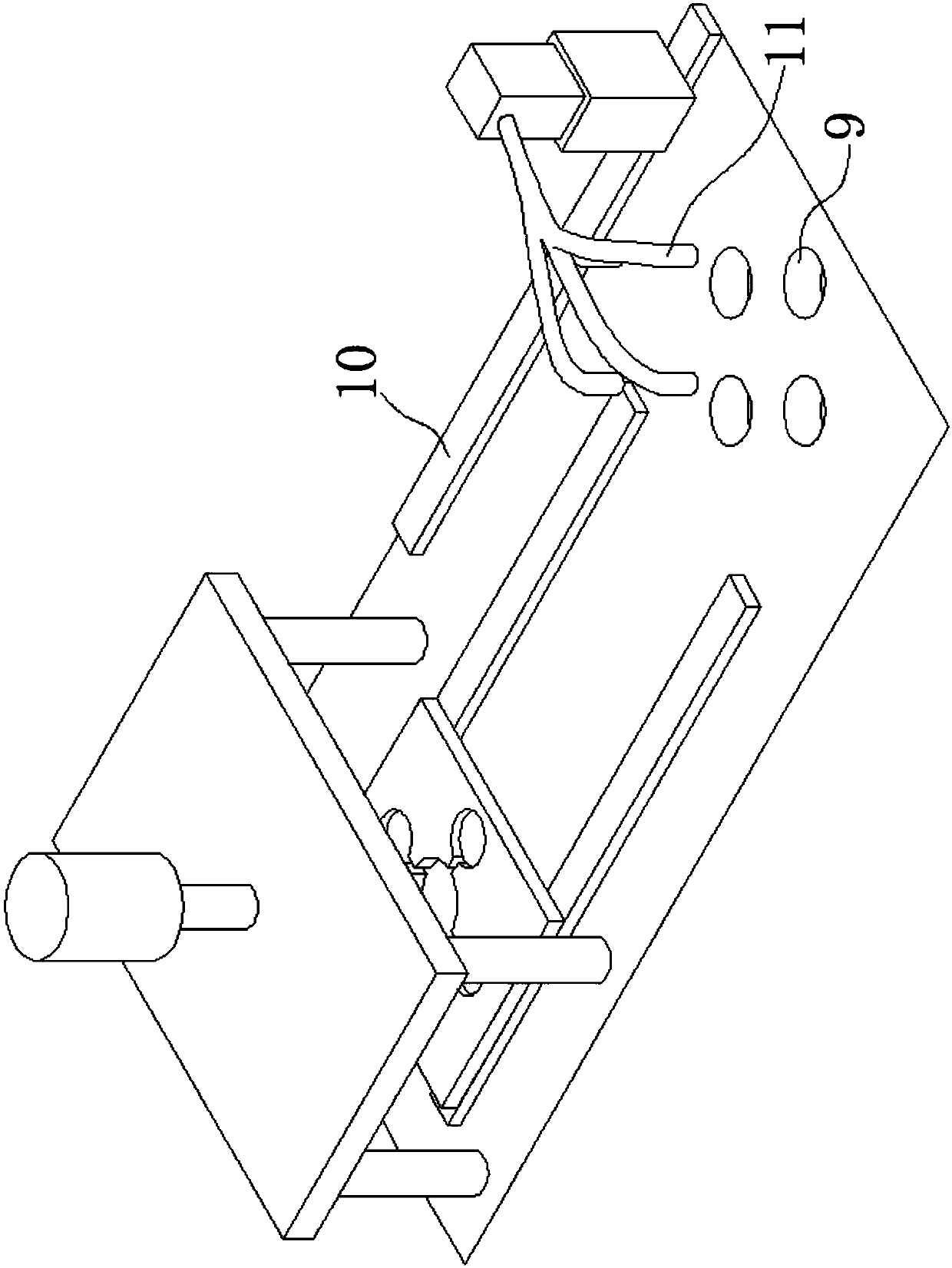

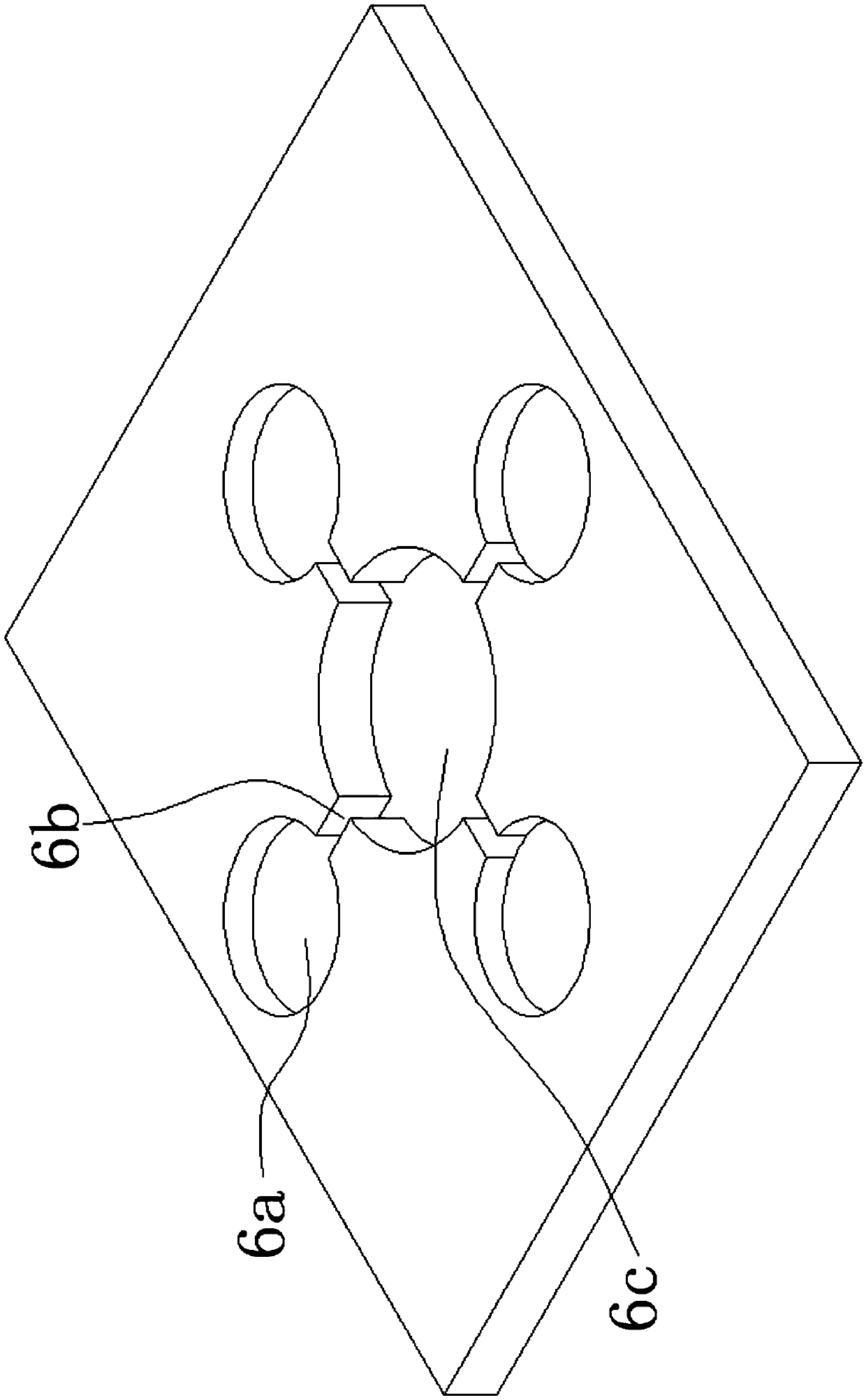

[0033] In order to achieve the purpose of the present invention, a product and waste separation equipment for plastic parts includes: a cutting mechanism with a cutter that cuts off from the junction of the product 7 and waste 8; a waste blanking mechanism with a workbench below the cutting mechanism 4. A waste material discharge opening 6 is provided directly below the cutter, and a sliding plate 6 is provided on the waste material discharge opening 5. The sliding plate 6 is provided with several product storage grooves 6a for accommodating products 7, and the product storage grooves 6a are in the shape of a ring array, the sliding plate 6 is equipped with a radial hole 6b for the waste material 8 to pass through and fall into the waste material discharge port 5, the radial hole 6b runs through the upper and lower surfaces of the sliding plate 6, and the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com