Rapid printing and drying equipment for paperboard for packaging

A technology for drying equipment and packaging, which is applied in the field of rapid printing and drying equipment for packaging cardboard, and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

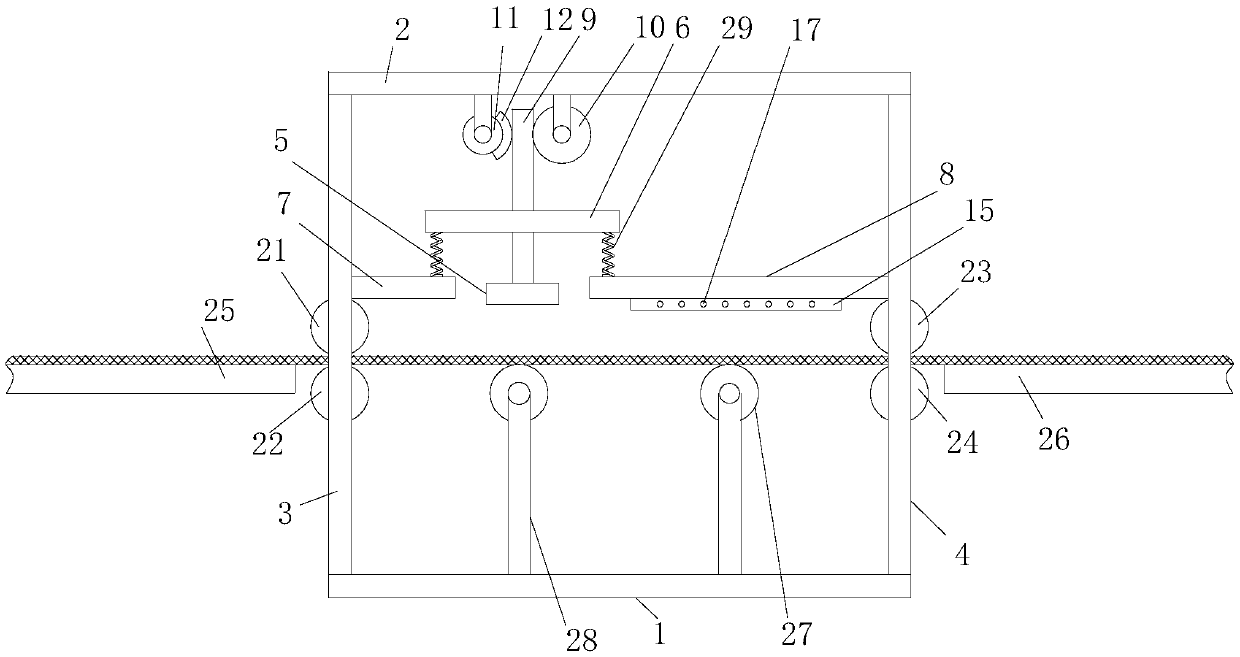

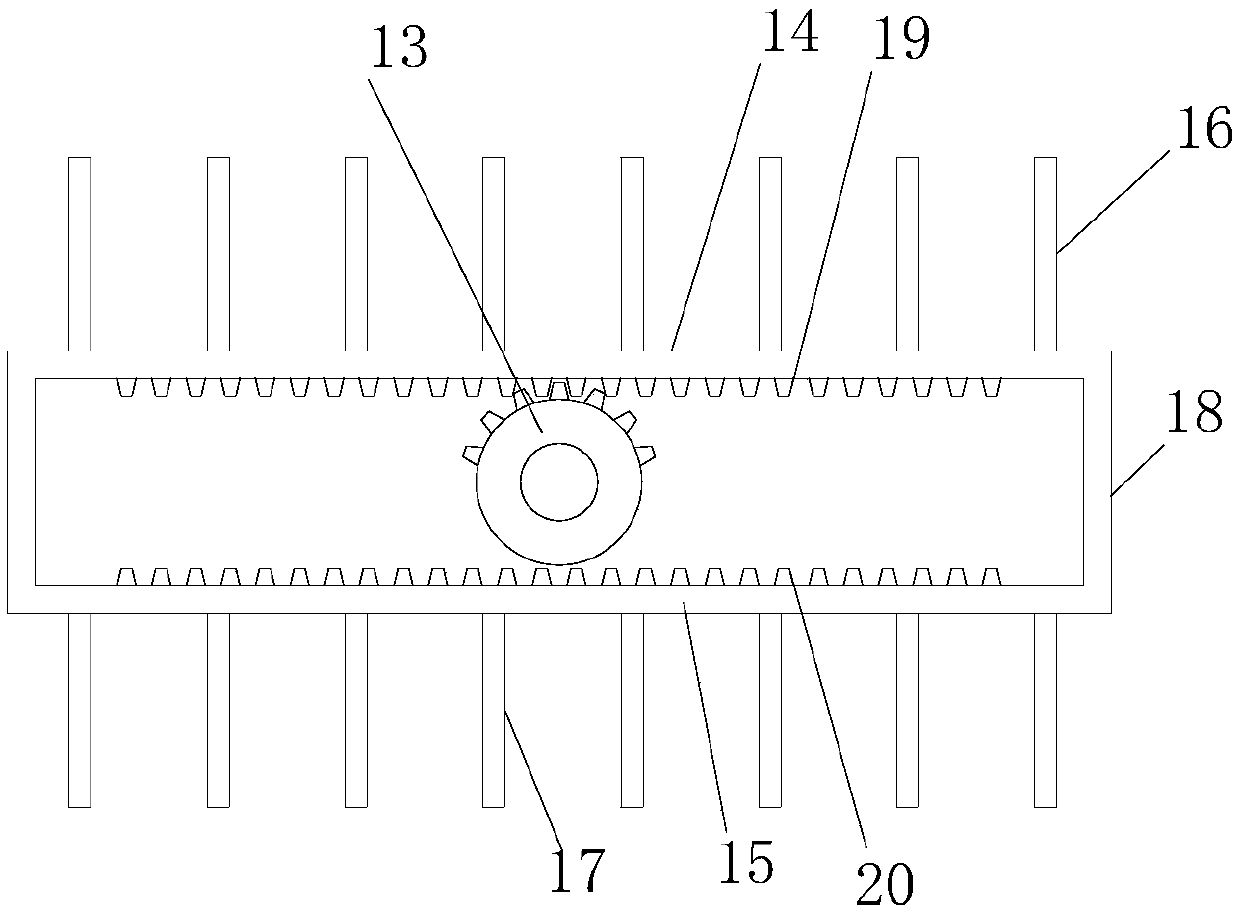

[0020] refer to figure 1 , figure 2 , the present invention proposes a fast printing and drying equipment for packaging cardboard, including a fixing mechanism, a cardboard conveying mechanism, a printing mechanism and a drying mechanism, wherein:

[0021] The fixing mechanism includes a first fixing frame 1, a second fixing frame 2, a first supporting frame 3 and a second supporting frame 4, the first fixing frame 1 is arranged horizontally, and the second fixing frame 2 is located above the first fixing frame 1 and parallel to The first fixed frame 1, the first support frame 3 are vertically arranged and the two ends of the first support frame 3 are respectively connected with the first end of the first fixed frame 1 and the first end of the second fixed frame 2, and the second support frame 4 is vertical Arranged and the two ends of the second supporting frame 4 are respectively connected with the second end of the first fixing frame 1 and the second end of the second fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com