Toothed rail train drive clutch device

A clutch device and train technology, applied in the transmission system of locomotives, locomotives, motor vehicles, etc., can solve the problems of severe clutch vibration, fast clutch wear, large meshing vibration, etc., to achieve convenient maintenance, stable function conversion, and safety factor. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

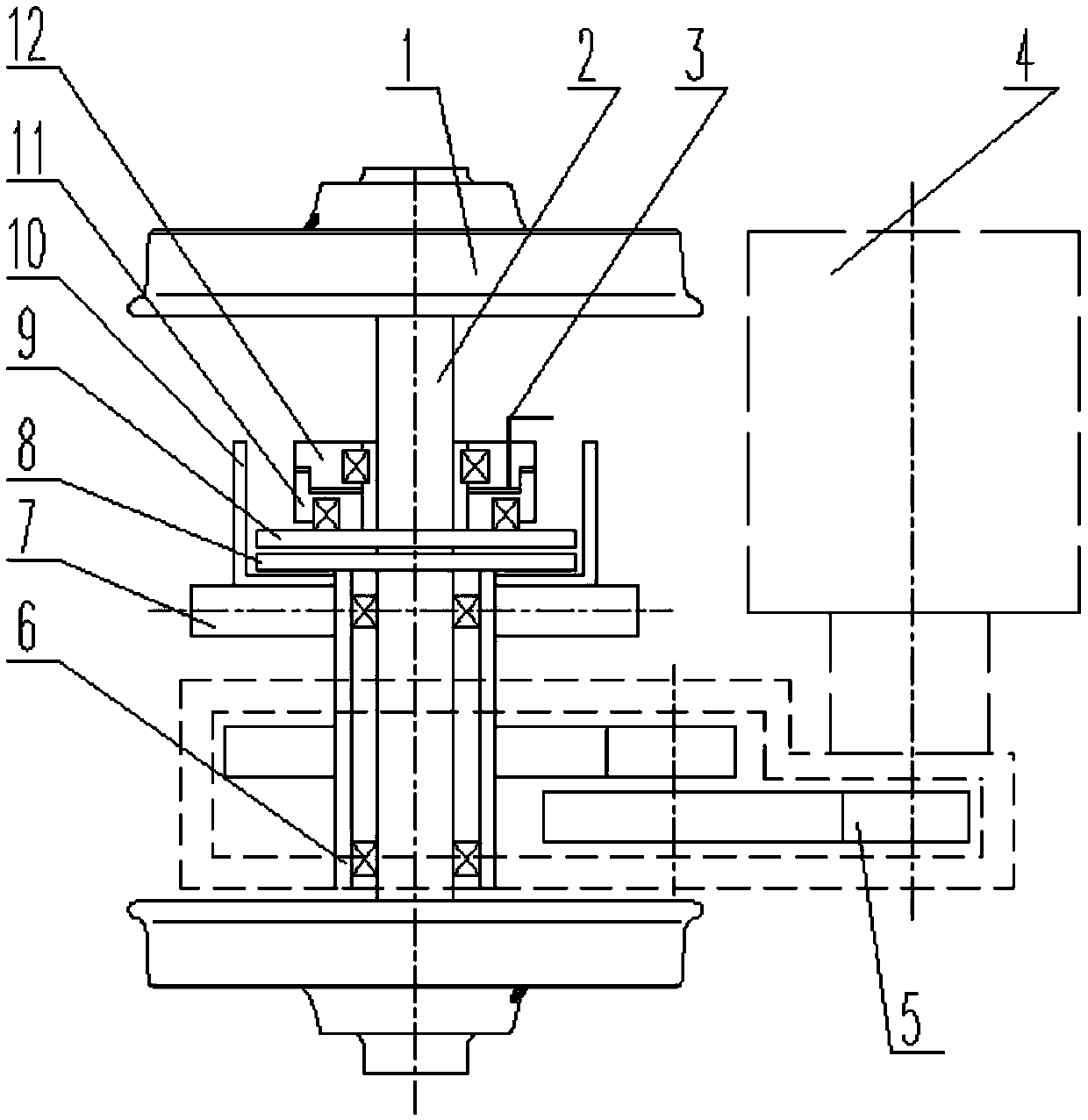

[0028] This embodiment provides a rack train drive clutch device, please refer to figure 1 , this cog train drive clutch device includes a drive part, a clutch part and a wheel part;

[0029] The wheel 1 part includes an axle 2 and a hollow shaft 6 sleeved on the outside of the axle 2, a bearing is arranged between the axle 2 and the hollow shaft 6 to ensure that they can rotate independently of each other, and the two ends of the axle 2 are fixedly connected to the wheel 1; One end of the clutch part is connected with the axle shaft 2 in the circumferential limit, and the other end is connected with the hollow shaft 6 in the circumferential limit; the outside of the hollow shaft 6 is provided with a drive gear 7 for cooperating with the rack line; the output end of the drive part is connected with the hollow shaft 6 The outer mating connection.

[0030] The hollow shaft 6 can be directly driven to rotate through the driving part, and the hollow shaft 6 drives the driving gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com