Design method of an axial flow high power density water jet propulsion pump

A high-power density, water-jet propulsion technology, applied in ship propulsion, propulsion components, ship construction, etc., can solve problems such as not being able to meet high power density, improve design accuracy, design efficiency, and reduce R&D and manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Embodiment: In order to obtain a water jet propulsion pump that can meet the requirements of high power density, this embodiment introduces a design method of a marine axial flow water jet propulsion pump. The speed of the carrier ship is 30kn, the power of the main engine is 20.5MW, the displacement is 1588.6t, and the draft is 1.6m.

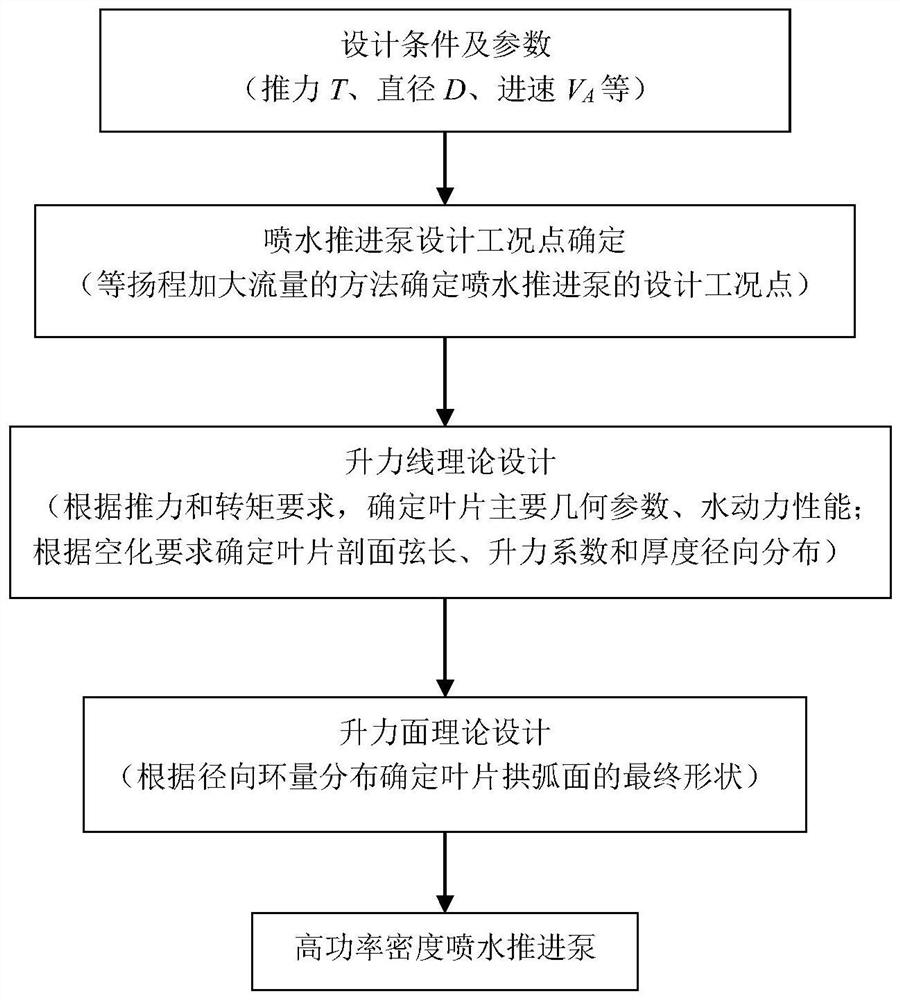

[0102] Such as figure 1 As shown, the design method of an axial-flow high power density water jet propulsion pump disclosed in this embodiment, the specific implementation steps are as follows:

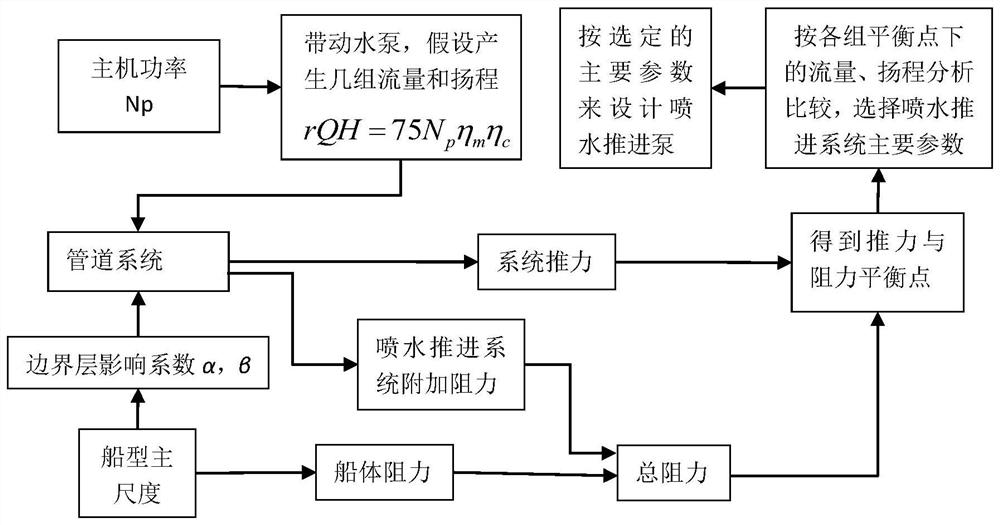

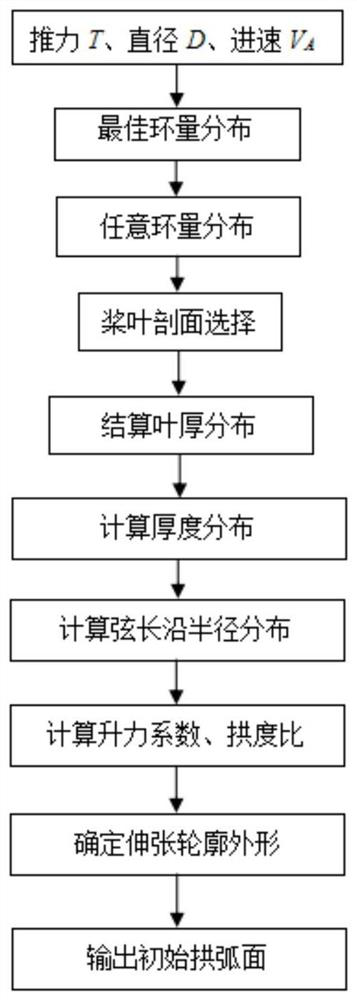

[0103]Step 1: Select the main parameters of the water jet propulsion system by comprehensively considering the performance of the power machine, the performance of the water jet propulsion system, and the interaction between the water jet propulsion system and the carrier. The parameters include: thrust T, head H, flow Q, impeller diameter D 0 , nozzle diameter D j .

[0104] On the waterjet propulsion carrier, when designing the waterjet pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com