Self-adaptation packaging box for logistics unmanned aerial vehicle

An unmanned aerial vehicle, self-adaptive technology, applied in the direction of packaging, transportation and packaging, and containers that prevent mechanical damage, etc., can solve the problem of inability to resist rain and humid air erosion, low reuse rate of cushioning inner packaging, and difficult ideal cushioning inner packaging Effect and other issues, to achieve the effect of ensuring transportation work efficiency, high modulus, and enhanced self-adaptive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

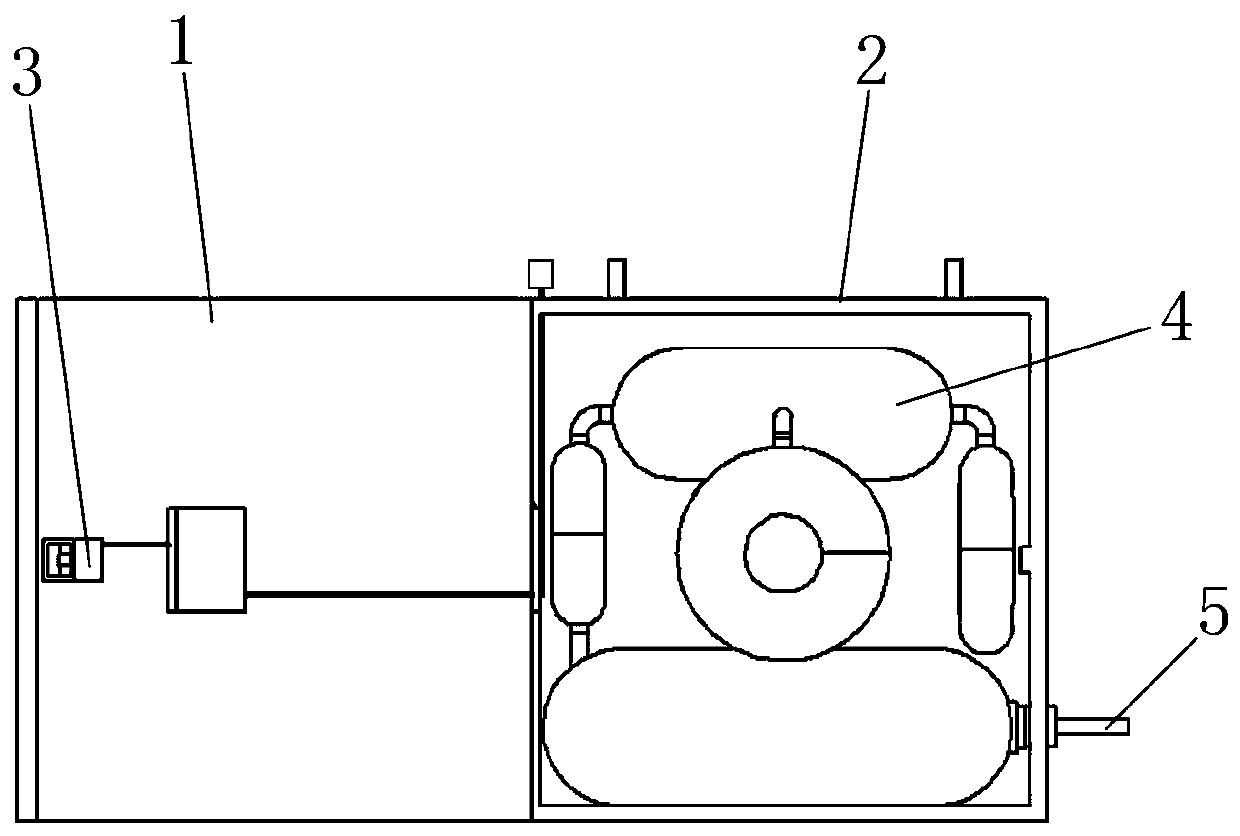

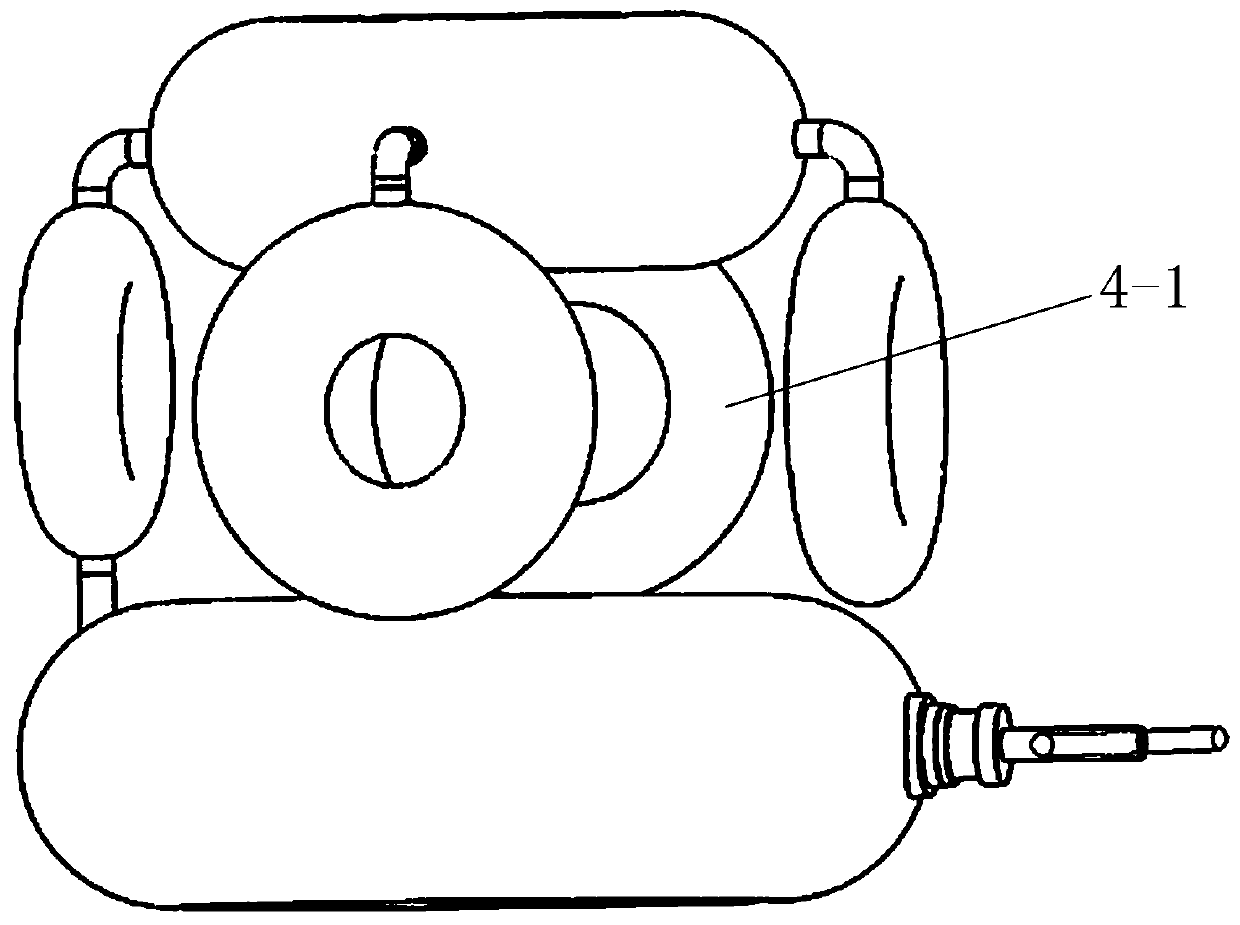

[0012] Embodiment 1, the airbag group 4 is composed of six annular airbags 4-1 connected to each other through flexible pipes, and an air nozzle 5 is arranged on one of the annular airbags 4-1; , left, right, up and down six directions form a comprehensive protection, and the annular airbag 4-1 has the advantages of being easy to inflate and expand, without sharp corners, and will not scratch the goods. The hose insertion technology is very mature, and more annular airbags 4-1 can be connected in series or in parallel as required.

Embodiment 2

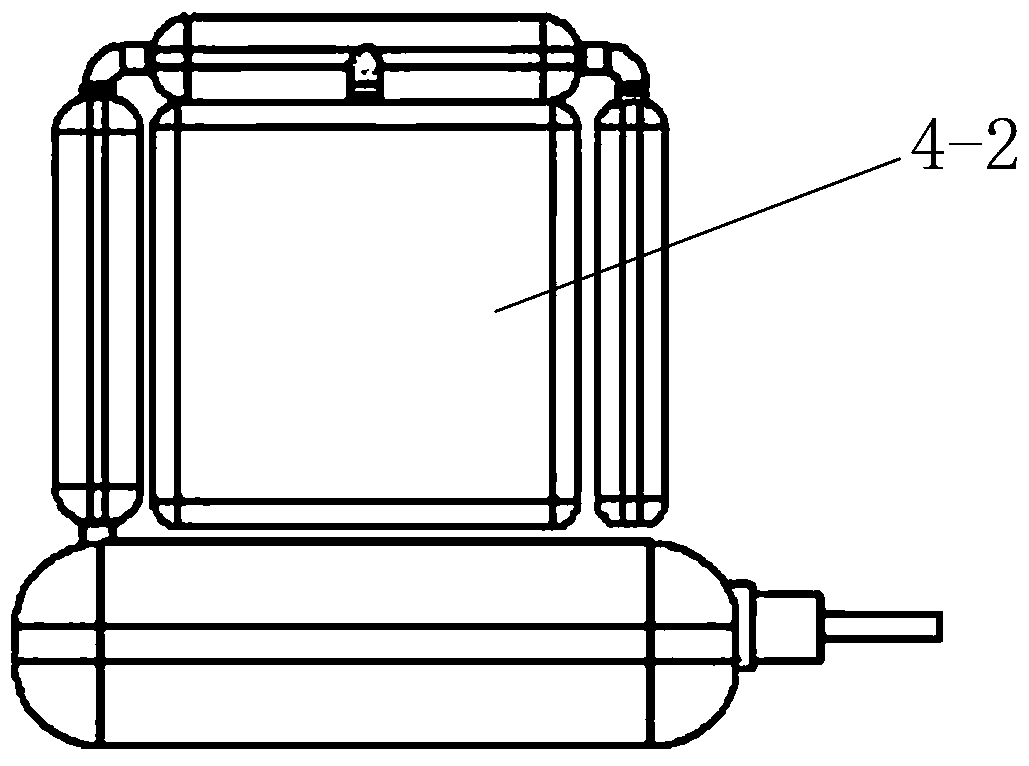

[0013] Embodiment 2, the airbag group 4 is composed of six square airbags 4-2 connected to each other through flexible tubes, and an air nozzle 5 is arranged on one of the square airbags 4-2.

Embodiment 3

[0014] Embodiment three, the airbag group 4 comprises that a square airbag 4-2 and a plurality of annular airbags 4-1 are arranged at the bottom of the casing 2, and the square airbag 4-2 is provided with an independent air nozzle 5, and all the annular airbags 4-1 are connected with Another air nozzle 5 is connected, and the square air bag 4-2 can be inflated earlier, and then other air bags are inflated after putting into the goods, and when taking out the goods, the square air bag 4-2 need not deflate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com