Conveying belt of bag feeding type intelligent vacuum packaging machine

A vacuum packaging machine and conveyor belt technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of slowing down the conveying speed of finished products, affecting the efficiency of transmission, and stacking of finished products. Keep it clean and tidy, easy to limit the effect of fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

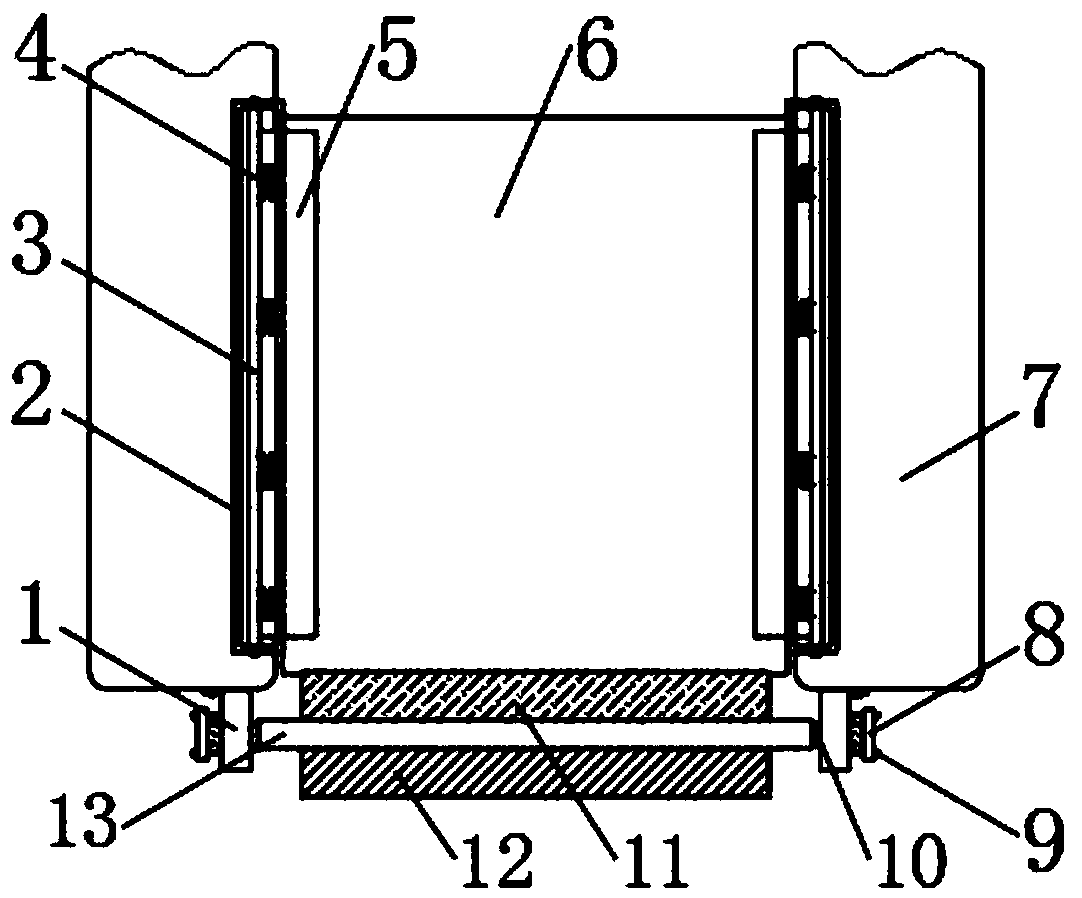

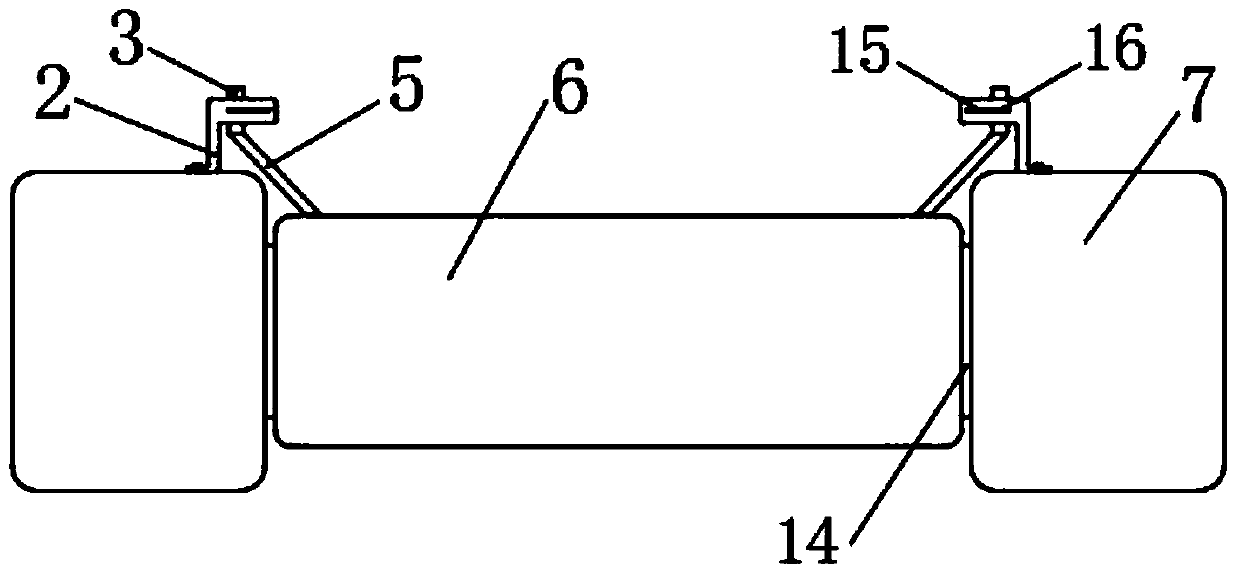

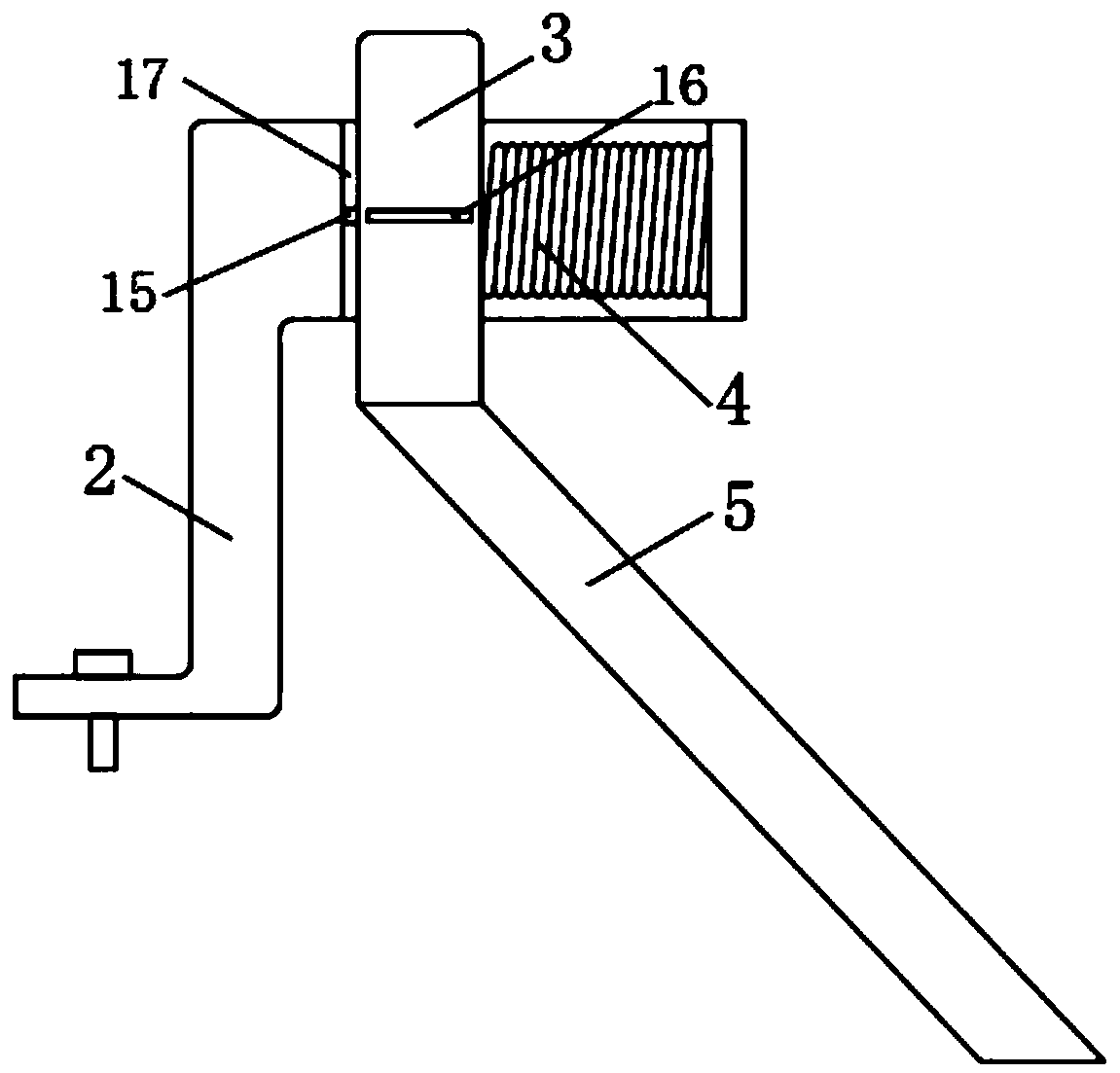

[0020] See Figure 1-Figure 4 , The present invention provides a technical solution: a conveyor belt for a bag-type intelligent vacuum packaging machine includes a main frame 7, a barrier mechanism, and a cleaning protection mechanism. The barrier mechanism includes a bracket 2, which is fixedly connected to the main frame 7. On the top surface, the top of the bracket 2 is provided with a rectangular groove 17 inside. One side of the inner wall of the rectangular groove 17 is fixedly connected with a spring 4, one end of the spring 4 is fixedly connected with a vertical plate 3, and the bottom of the vertical plate 3 is integrated and fixedly connected with a diagonal Plate 5, through the design of the inclined plate 5 and the vertical plate 3, the inclined plate 5 can prevent the finished product from overflowing from the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com