Heat shaping device used for wall plate cover shell

A heat setting and cover technology, applied in heat treatment furnaces, furnace types, heat treatment equipment, etc., can solve the problem that the diameter of the inner hole of the flange cannot reach the size of the inner hole of the flange, the diameter of the inner hole of the flange is difficult to maintain, and the wall plate cover cannot be put into use. Use and other issues to achieve the effect of convenient processing and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

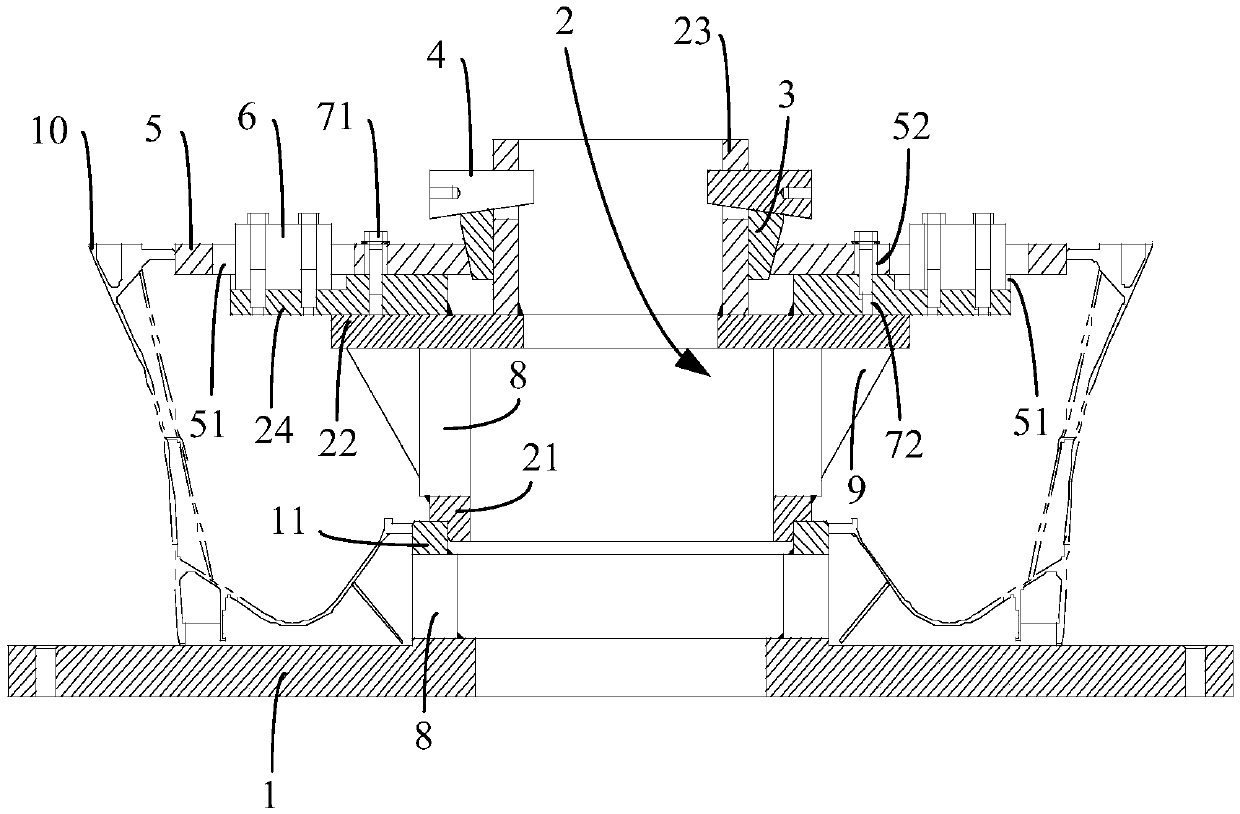

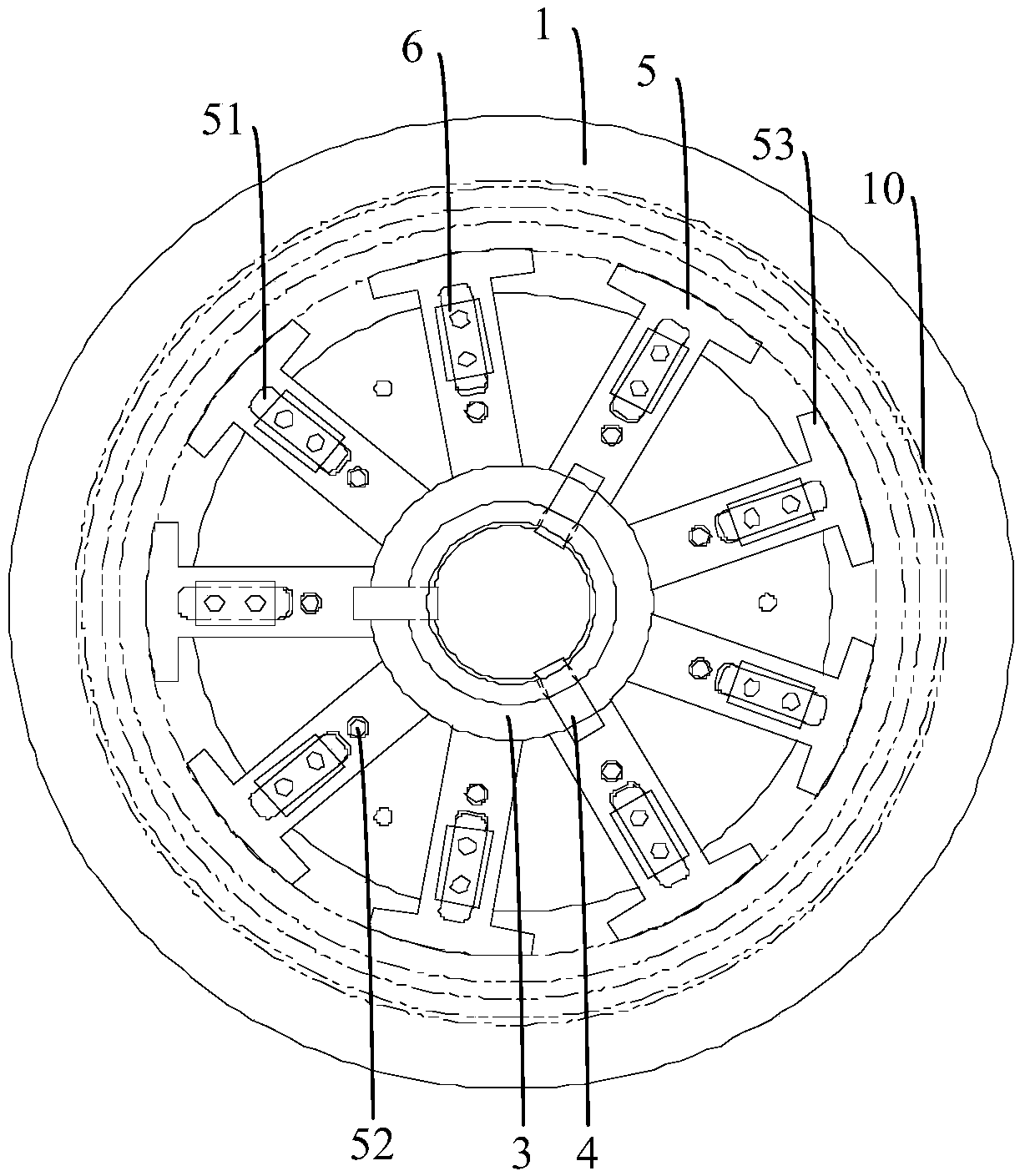

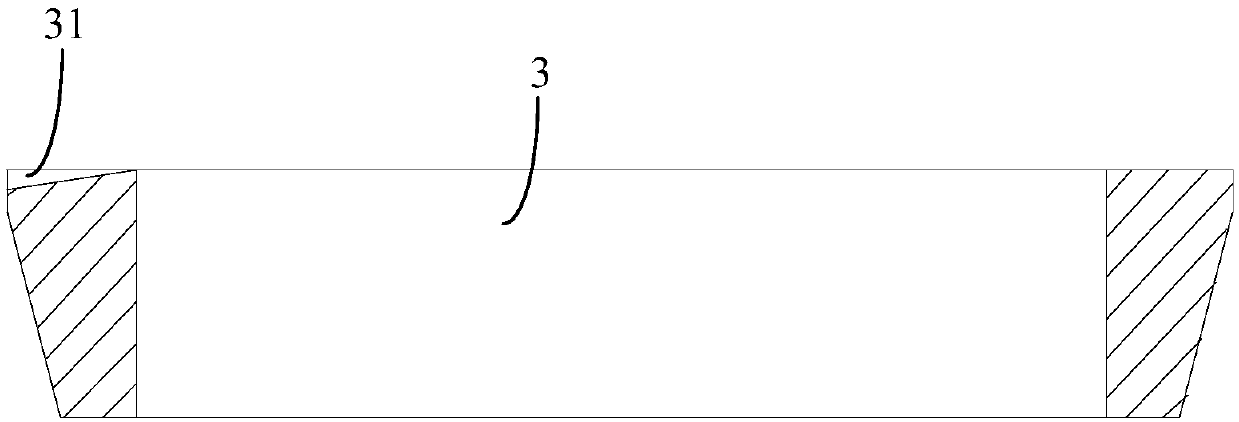

[0026] figure 1 It is a structural schematic diagram of a heat setting device for a wall panel shell provided by an embodiment of the present invention, figure 2 It is a top view of a heat setting device for a wall panel shell provided by an embodiment of the present invention. Such as figure 1 , 2 As shown, the heat setting device includes: a positioning chassis 1 , a positioning bracket 2 , a positioning cone ring 3 , a positioning cone block 4 , a positioning expansion block 5 and a guide block 6 . One side of the positioning chassis 1 is provided with a housing positioning ring 11 coaxially arranged with the positioning chassis 1, and the positioning bracket 2 includes: installing a positioning ring 21, a support plate 22, a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com