Hanging basket and rear anchor connection structure for municipal bridge engineering construction

A technology for bridge engineering and connecting structures, which is applied in bridges, bridge construction, erection/assembly of bridges, etc. It can solve problems such as deflection of anchorages, reliable connection of tie rods that are difficult to hang, and achieve high dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

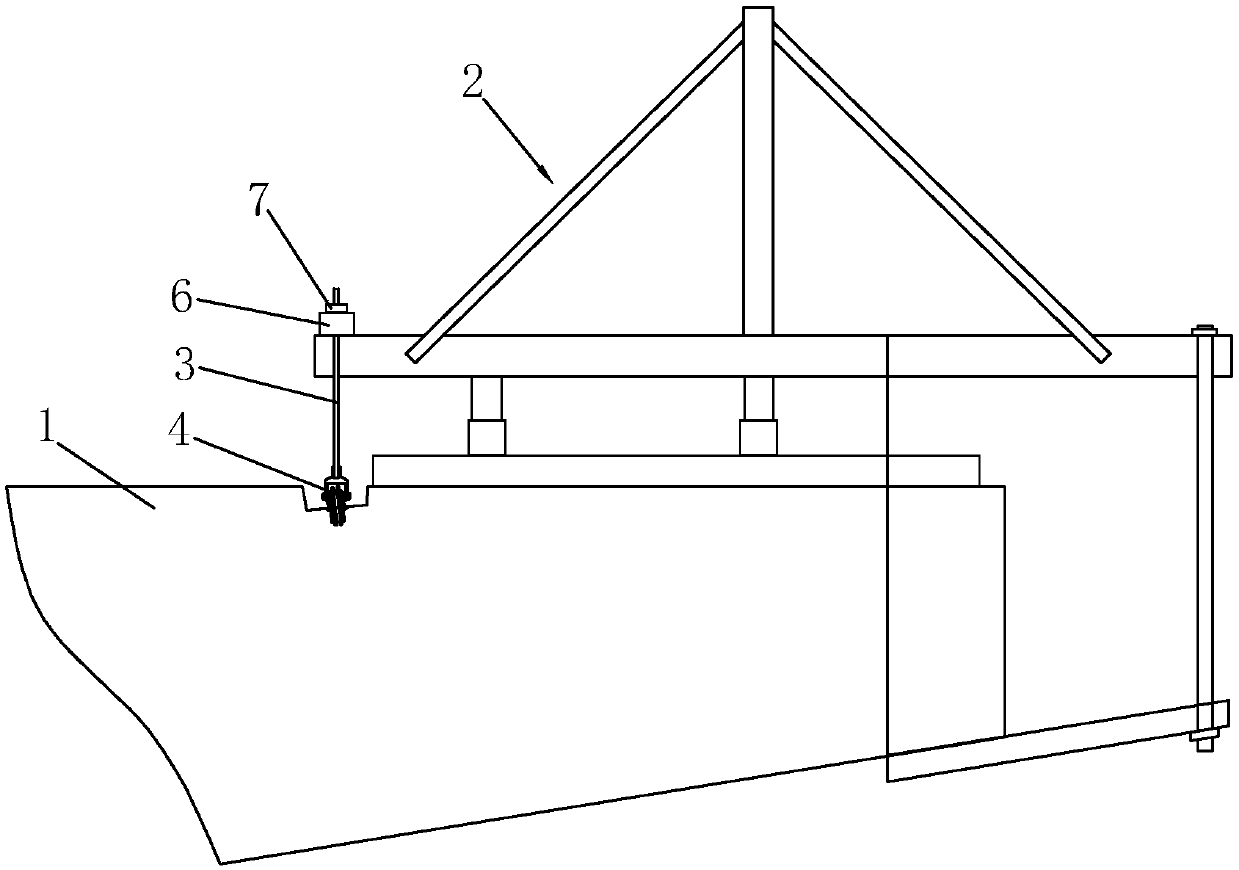

[0025] A kind of municipal bridge engineering construction hanging basket rear anchor connection structure, such as figure 1 As shown, the rear anchor system including the box girder 1, the hanging basket 2 and the hanging basket 2, the rear anchor system includes a tie rod 3, and a vertical secondary tension anchor 4 arranged on the box girder 1; the tie rod 3 is a fine-rolled thread rebar. One end of the tie rod 3 is connected with the vertical secondary tensioning anchor 4, and the other end is anchored with the rear upper beam 6 of the hanging basket 2 through the threaded end cap 7.

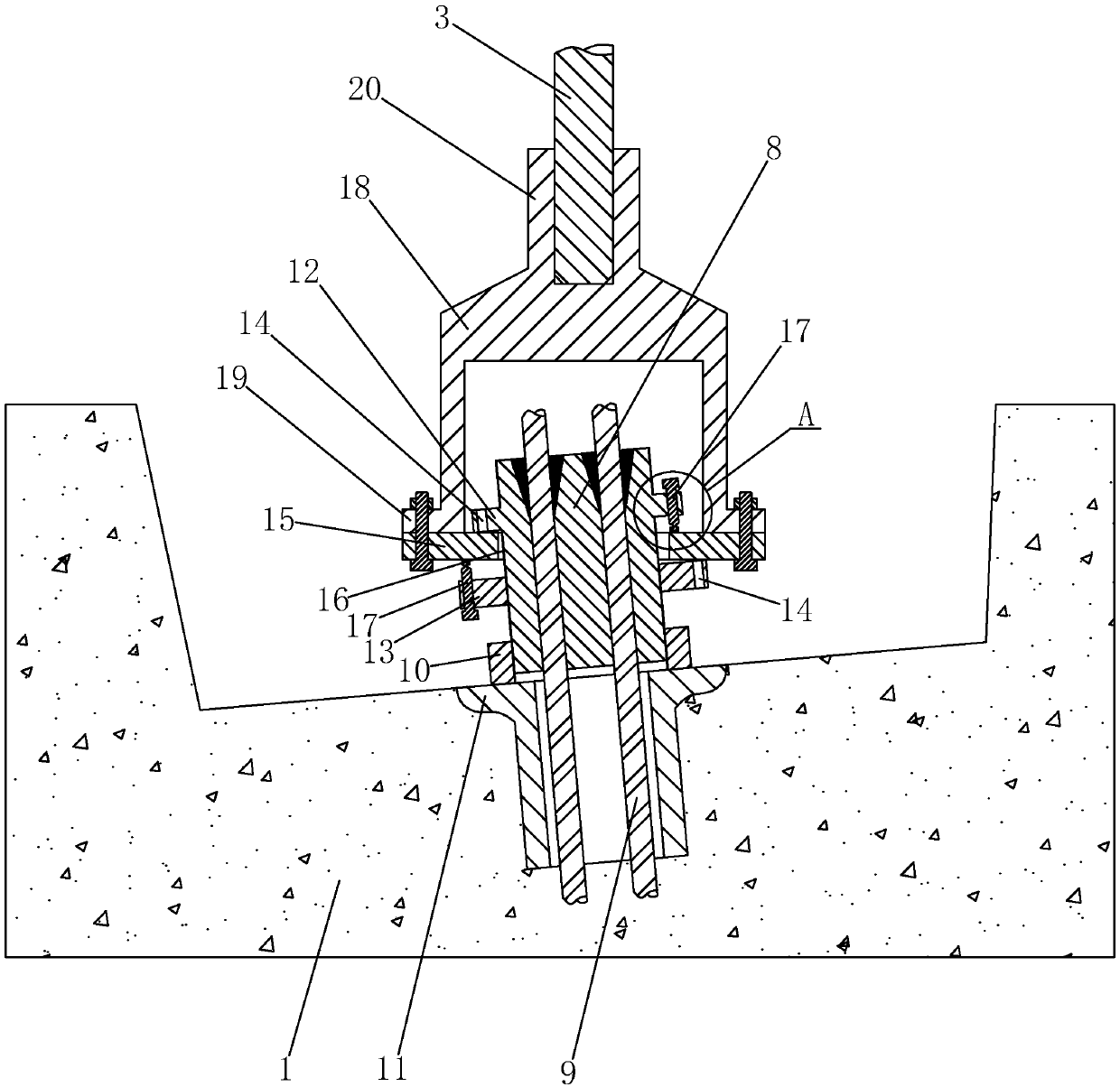

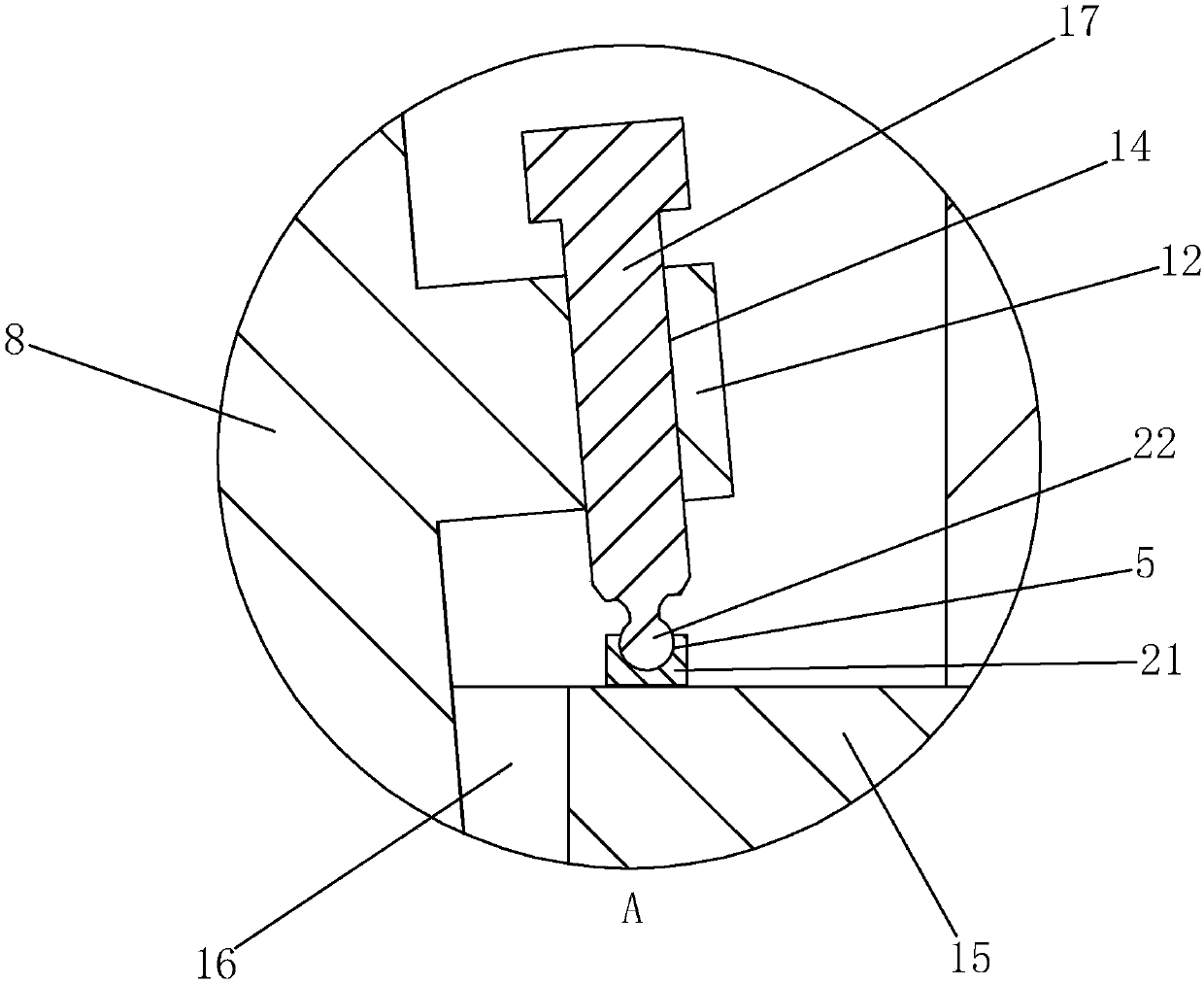

[0026] Such as figure 2 As shown, the vertical secondary tension anchor 4 includes an anchor cup 8, a steel strand 9, a support nut 10 and an anchor backing plate 11; And conflict with the anchor backing plate 11. The outer wall of the anchor cup 8 is provided with a flanging 12, and the flanging 12 is arranged on the middle and upper part of the anchor cup 8; The anchor cup 8 is screwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com