Bag grouting well wall sealing structure

A bagging and grouting technology, which is applied in infrastructure engineering, construction, etc., can solve the problems that the backfill water-stopping effect is not easy to control, the grouting effect cannot be tested, and the well wall is gushing water, etc., so as to improve the well wall water-stopping effect, Guarantee the effect of well wall water stop and fast well wall water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

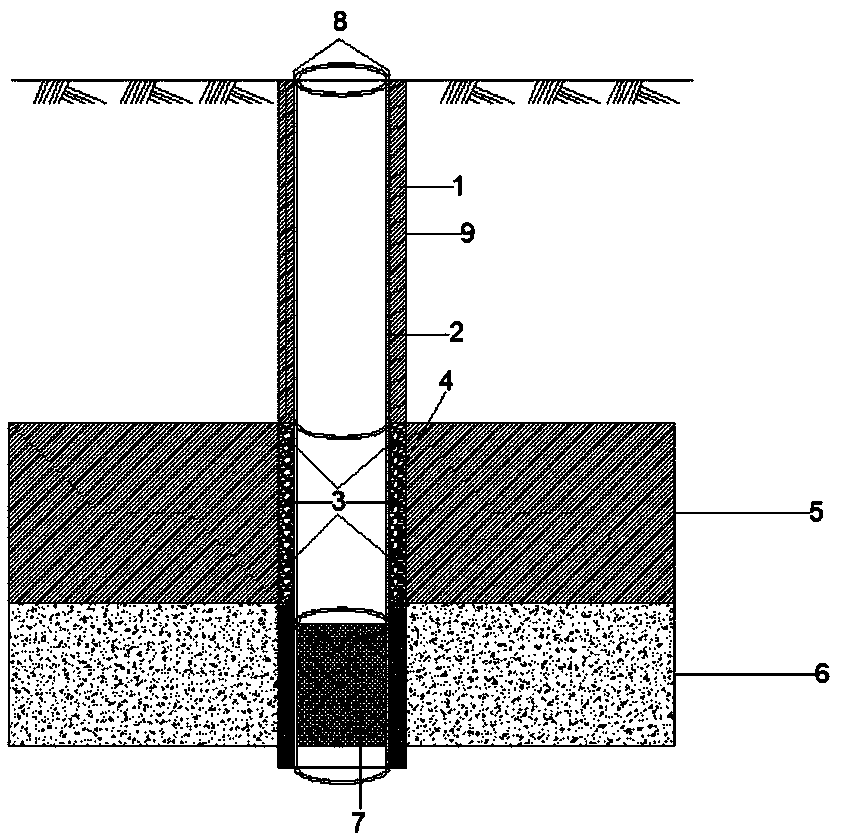

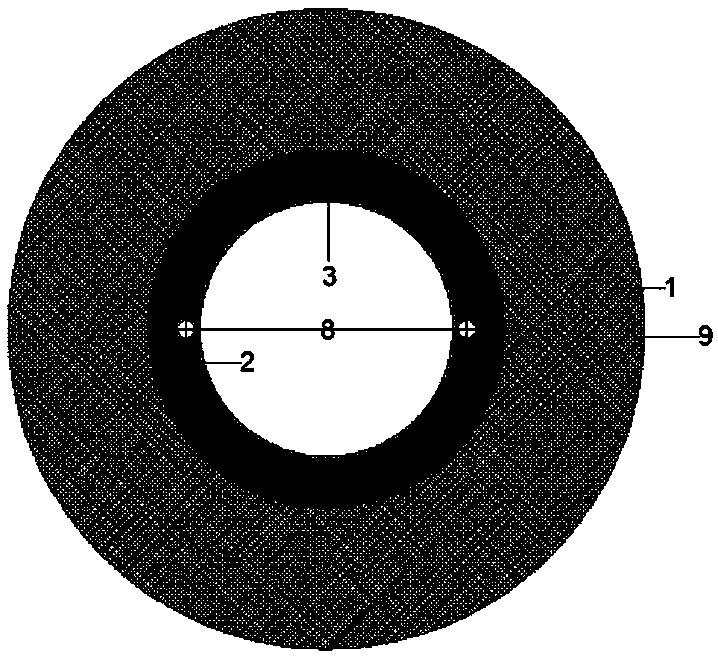

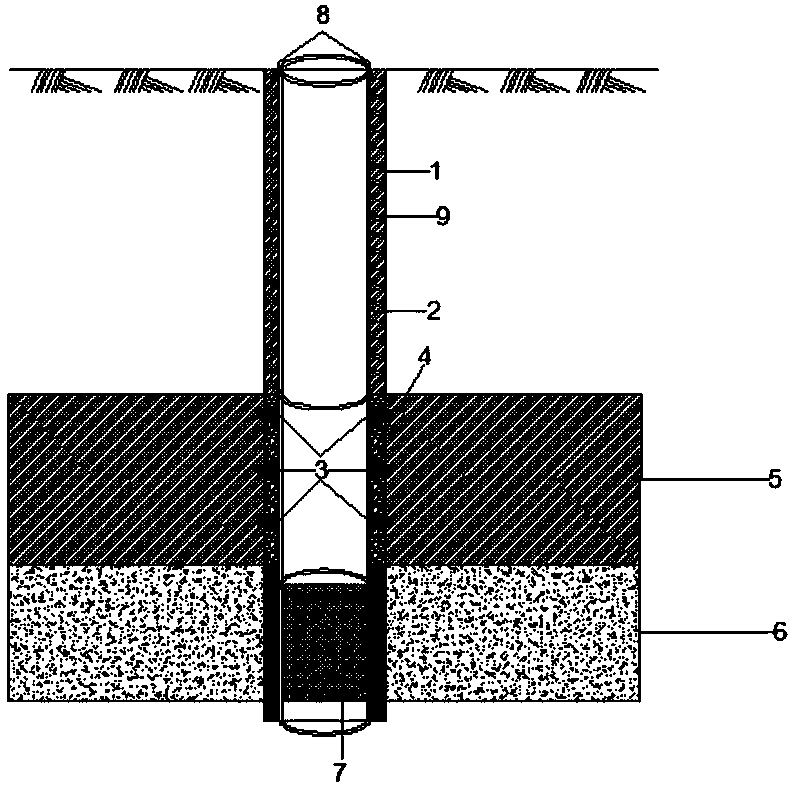

[0019] Embodiment: A bag grouting well wall water-stop structure, characterized in that it includes a bag 3 and a grouting pipe 8; the bag 3 is fixed on the outer wall of the well pipe 2; the bag 3 is connected to the grouting Pipe 8; after grouting in the pocket 3, the pocket 3 expands until the hole wall 9 is fully in contact with the original soil body or expanded and embedded in the original soil body.

[0020] The bladder 3 is fixedly arranged on the outer wall of the well pipe 2 in layers.

[0021] Between the outer wall of the well pipe 2 and the hole wall 9 is a packing layer 4 .

[0022] The packing layer 4 includes a filter material layer and a water-stop layer.

[0023] The lower part of the well pipe 2 is backfilled with filter material corresponding to the aquifer 6 to form a filter material layer, and the upper part of the filter material layer is backfilled with clay 1 corresponding to the water-resistant layer 5 to form a water-stop layer.

[0024] The pouch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com