Grouting pipe connecting structure at ground crack

A technology for grouting pipes and ground fissures, which is applied to underground chambers, underwater structures, and infrastructure engineering, etc. It can solve the problems of easy blockage of holes, troubles for construction teams, and non-reusability, etc. Filling effect, fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

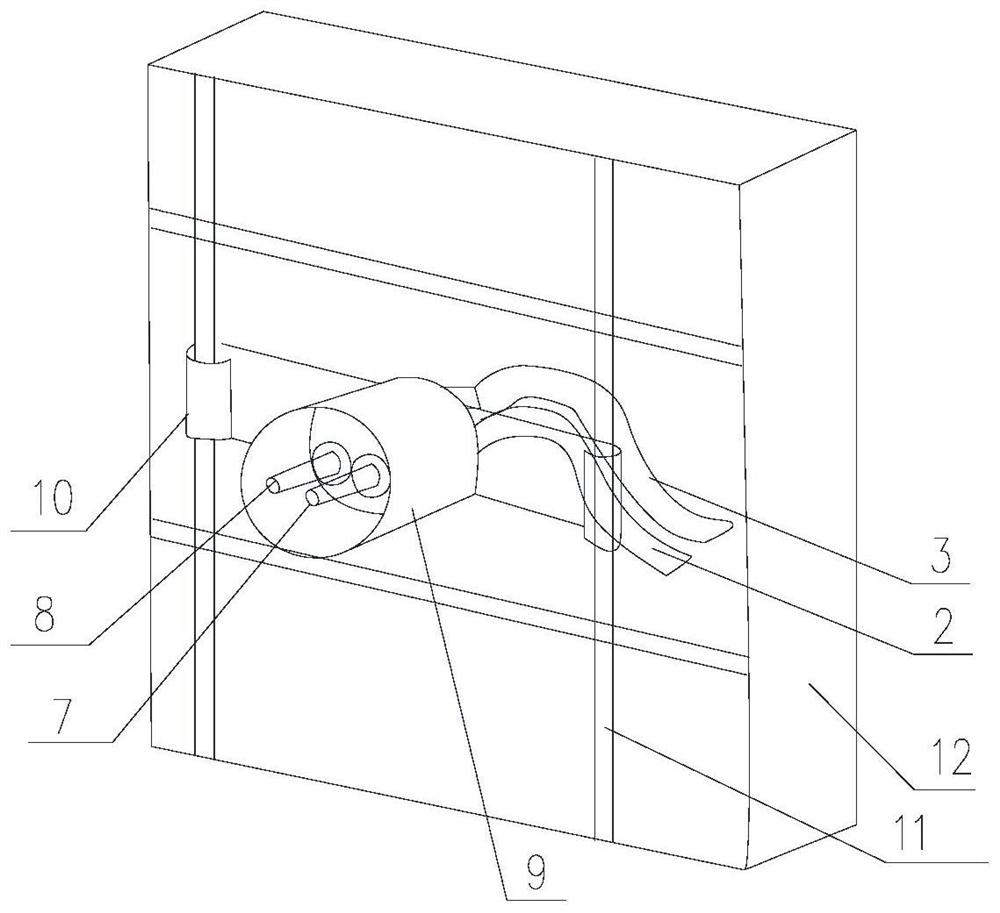

[0019] The specific implementation manners according to the present invention will be described below in conjunction with the accompanying drawings.

[0020] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from those described here, therefore, the present invention is not limited to the specific embodiments disclosed below limit.

[0021] In order to solve the problems of complex procedures, time-consuming and labor-intensive traditional construction methods, inability to be flexibly used in multiple cracks, and poor plugging effect, the invention provides a connection structure for grouting pipes at ground fissures.

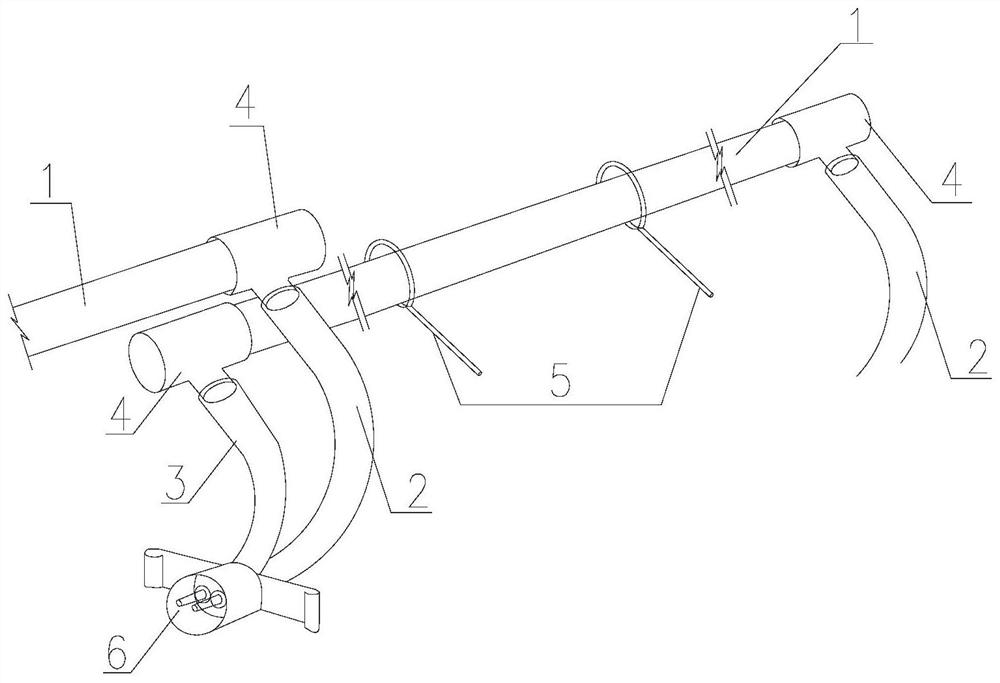

[0022] Such as figure 1 As shown, the grouting pipe connection structure at the ground fissure includes at least two grouting pipe structural units, wherein a single grouting pipe structural unit includes: grouting pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com